Ferro-nickel-cobalt-titanium alloy with room-temperature sheet martensitic structure and preparation method thereof

A technology of martensite and iron-nickel-cobalt, which is applied in the field of heat treatment, can solve the problems of not obtaining thin-sheet martensite, not obtaining the magnetic control shape memory effect, insufficient research on the composition design of iron-nickel-cobalt-titanium alloy and heat treatment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Composition: Ni: 29.05-31.88%, Co: 10-20%, Ti: 3.76-4.94%, and the rest is Fe;

[0026] Casting process: select 99.9% pure iron, 99.9% pure nickel, 99.9% pure cobalt, 99.9% pure titanium, mix according to weight percentage, and carry out vacuum arc melting or induction melting under the protection of argon to obtain block alloy materials.

[0027] Processing technology: After the alloy is cast, it is homogenized at about 1000-1200°C for 5-30 hours; forged at 900-1100°C to form a plate. Heat treatment at 1100-1200°C for 30 minutes, recrystallization treatment, and water quenching.

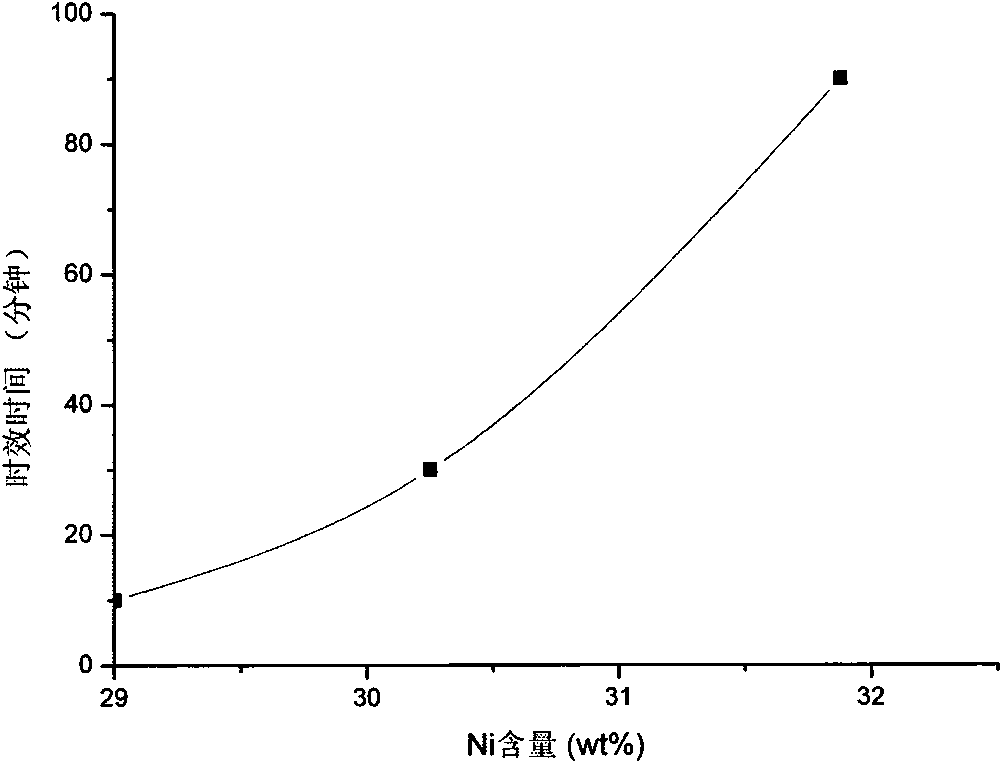

[0028] Aging process: The aging temperature is 500°C to 650°C, and the aging time is selected according to the change of the alloy composition. When the transformation start temperature is close to room temperature, the martensite is maintained at room temperature, with the largest amount of lamellar martensite.

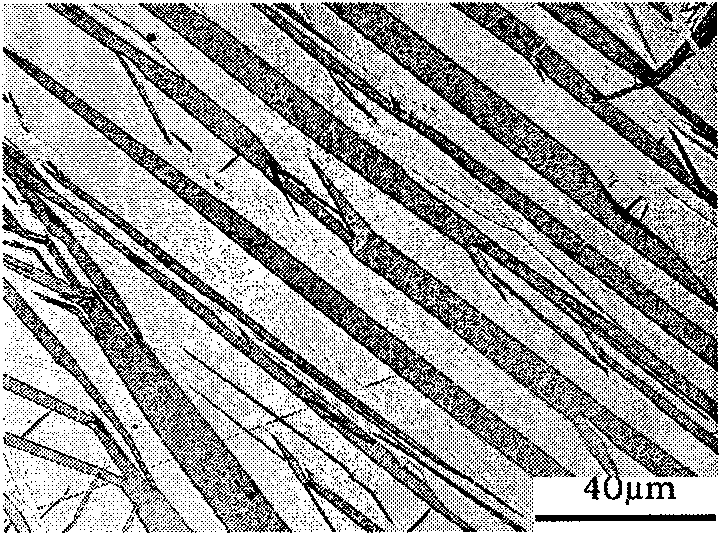

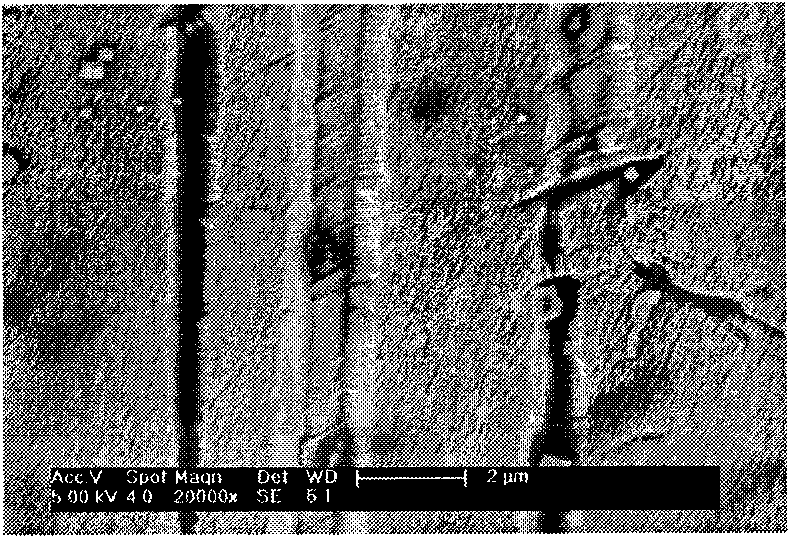

[0029]As shown in Figure 2, Fig. 2 (a) is the optical metallographic photogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com