Air textured yarn of full-dull flame-resistant terylene, preparation method and applications thereof

A technology of full-dull polyester and flame-retardant polyester, which is applied in the field of textured yarn to achieve good flame-retardant effect, good durability and water resistance, and good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

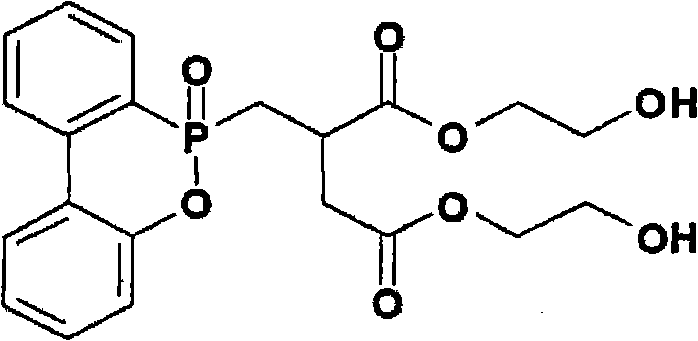

Image

Examples

Embodiment 1

[0027] According to the weight ratio, blend 1 part of flame-retardant masterbatch and 99 parts of full-dull polyester fiber-forming polyester (PET) in a plastic pelletizer, blending temperature: 260 ° C, screw speed: 100 rpm; and then use conventional screw extrusion The method of machine extrusion and pelletizing is used to prepare special resin chips for full-dull flame-retardant polyester fibers.

[0028] Pre-oriented PET fibers with flame retardant properties were prepared by pre-orienting the above slices through a conventional spinneret: the spinneret was produced by Wuzhong Spinneret Co., Ltd., the spinning temperature in the spinning machine: 280 ° C, the spinning speed : 4000m / min, the number of spinneret holes is 36.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com