Flame-retardant decorative veneer and manufacturing method thereof

A veneer and veneer layer technology, which is applied in the direction of wood layered products, wood veneer bonding, chemical instruments and methods, etc., can solve the problems of difficult promotion, small heating area, low heating efficiency, etc. Good performance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1. Cut the beech wood into 0.3mm veneer to make beech veneer material;

[0067] 2. Soak the beech veneer material in the BL-environmentally friendly flame retardant solution with a concentration of 30% by mass, keep the soaking temperature at 50°C, soak for 40 minutes, take it out to obtain soaked beech veneer, and then spread the soaked beech veneer, Drying treatment is carried out at a temperature of 25-30°C until the moisture content of the beech veneer is 14%, and the flame-retardant beech veneer 3 is obtained;

[0068] The prepared flame-retardant veneer has a moderate moisture content, so as to ensure that the composite veneer has good flexibility and will not crack when the wood is bent due to low moisture content. At the same time, it will not crack due to shrinkage of the veneer due to excessive moisture content after construction. The flame retardant used in the embodiment of the present invention selects BL-environmental protection flame retardant for use, ex...

Embodiment 2

[0080] 1. Cut the beech wood into 0.4mm veneer to make beech veneer material;

[0081] 2. Soak the beech veneer material in the BL-environmentally friendly flame retardant solution with a concentration of 40% by mass. Keep the soaking temperature at 40°C. After soaking for 30 minutes, take it out to obtain soaked beech veneer, and then spread the soaked beech veneer. Drying treatment is carried out at a temperature of 30-40°C until the moisture content of the beech veneer is 16%, and the flame-retardant beech veneer is obtained;

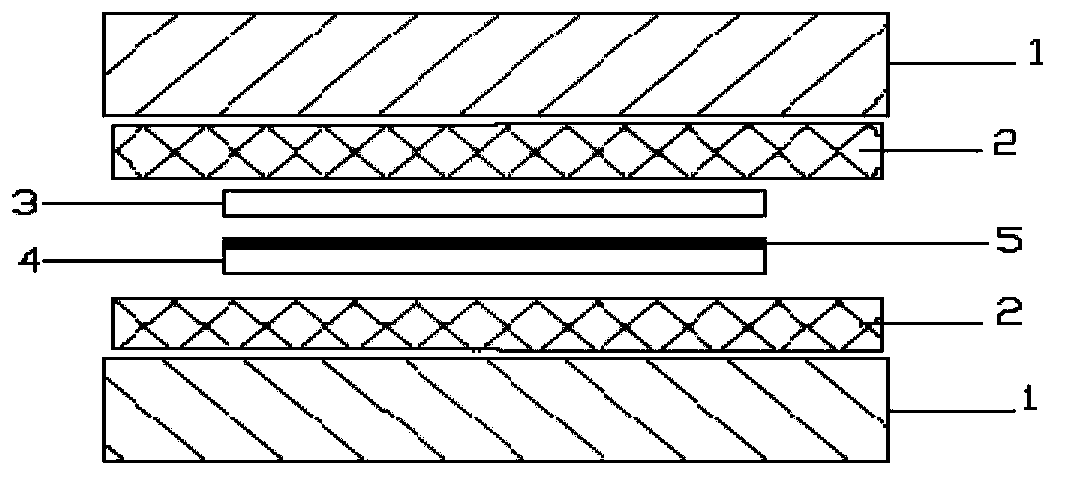

[0082] 3. Set two PTFE films 2 between the upper and lower hot-pressed steel plates 1 of the wood-based panel hot press, and then assemble the blanks between the upper and lower PTFE films 2 in the order from bottom to top , that is, place cotton mesh cloth, PES film and flame-retardant veneer 3 in sequence from bottom to top to form a blank to obtain a pre-pressed slab. The schematic diagram of flame-retardant decorative veneer assembly is as follow...

Embodiment 3

[0091] 1. Cut beech wood into 0.20mm veneer to make beech veneer material;

[0092]2. Soak the beech veneer material in the BL-environmentally friendly flame retardant solution with a concentration of 50% by mass, keep the soaking temperature at 70°C, soak for 20 minutes, take it out to obtain soaked beech veneer, and then spread the soaked beech veneer, Carry out drying treatment at a temperature of 20-25°C until the moisture content of the beech veneer is 15% to obtain a flame-retardant beech veneer;

[0093] 3. Set two PTFE films 2 between the upper and lower hot-pressed steel plates 1 of the wood-based panel hot press, and then assemble the blanks between the upper and lower PTFE films 2 in the order from bottom to top , that is, place cotton mesh cloth, PES film, and flame-retardant veneer 3 in sequence from bottom to top to prepare a pre-pressed slab. The schematic diagram of the flame-retardant decorative veneer assembly is as follows figure 1 As shown, the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com