Variable compression ratio device of automobile engine

An automotive engine and compression ratio technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of large changes to the engine, complex mechanical structure, and low development cost of variable compression ratio engines, achieving light weight, Low cost and low motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

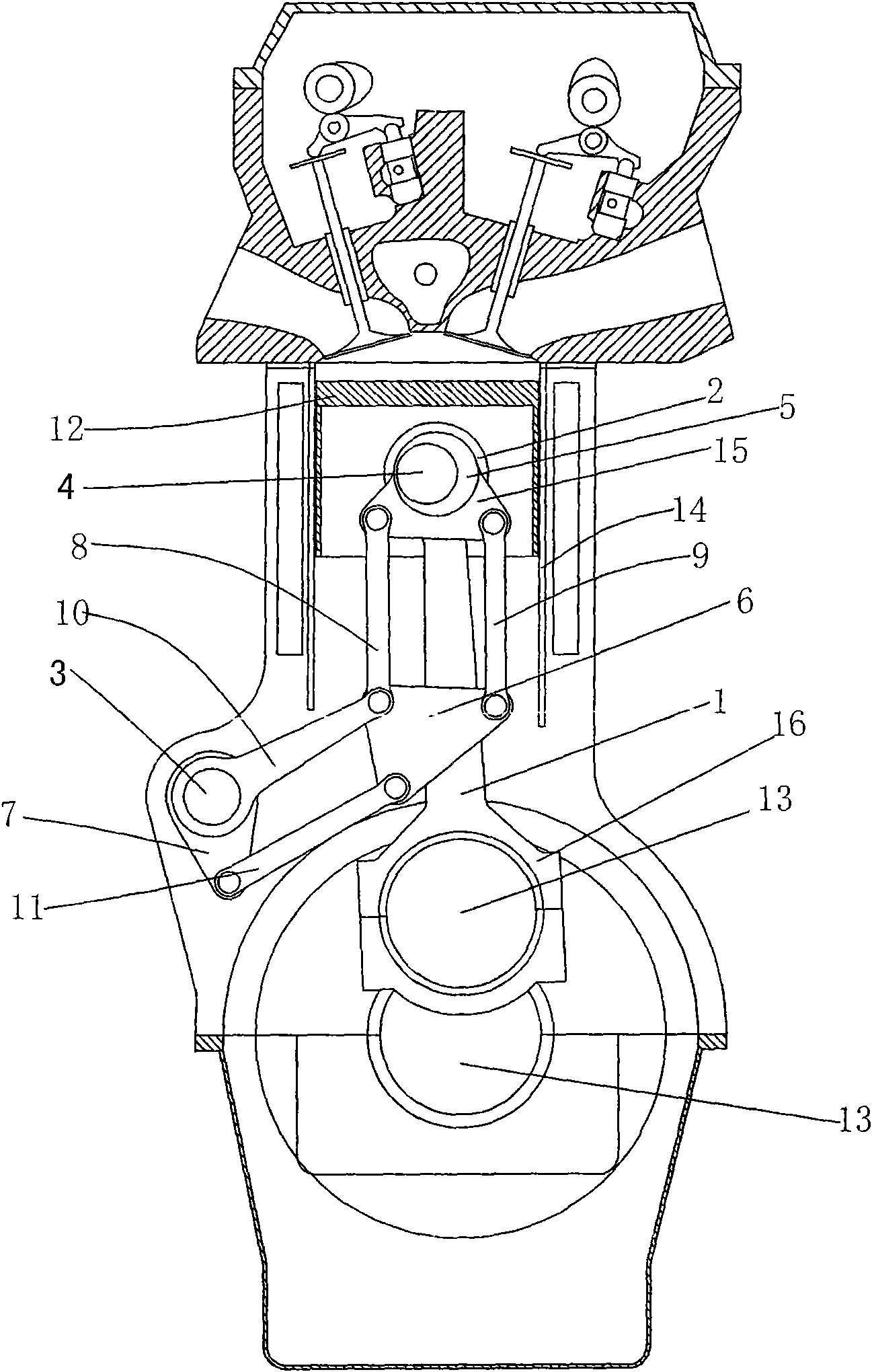

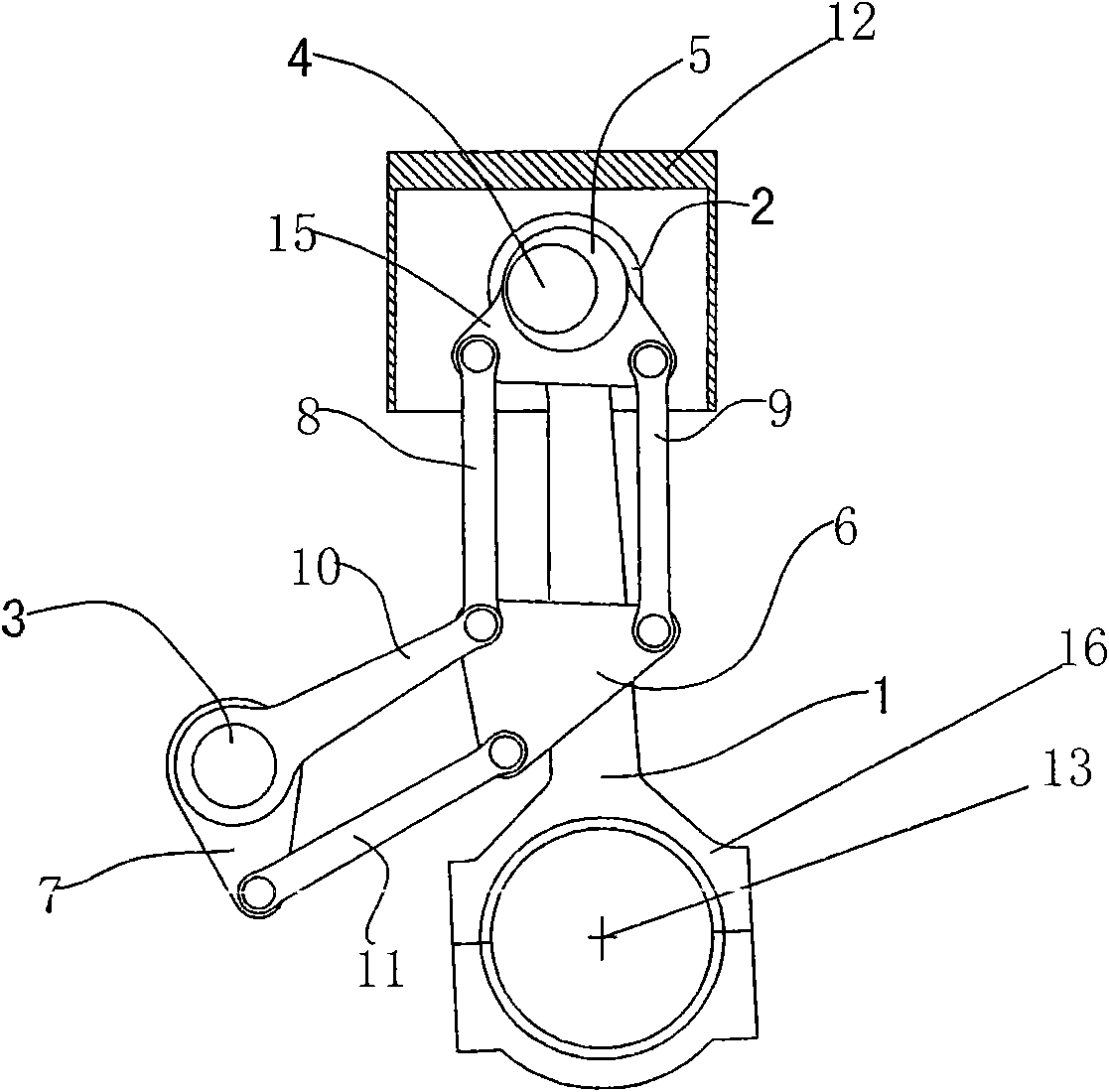

[0015] Such as figure 1 , figure 2 As shown, the main connecting rod 1 of the engine is connected to the crankshaft 13, the piston 12 in the cylinder 14 is connected to the small head 2 of the main connecting rod through the piston pin 4, and an eccentric bushing is arranged between the piston pin 4 and the small head 2 of the main connecting rod The sleeve 5 and the eccentric bushing 5 are fixedly connected with two ear arms 15, and the two ear arms 15 are respectively hinged with the first connecting rod 8 and the second connecting rod 9, and the first connecting rod 8 and the second connecting rod 9 are respectively connected with the replacement The reversing frame 6 is hinged with the third link 10 and the fourth link 11 respectively, and the third link 10 is hinged with the adjustment shaft 3, and the fourth link 11 is hinged with the drive arm 7 connected to the adjustment shaft 3, thereby forming a second parallelogram hinge four-bar mechanism; the drive arm 7 is con...

Embodiment 2

[0017] The eccentric bushing 5 is arranged between the main journal of the crankshaft 13 and the main bearing seat hole of the crankcase, and the others are the same as in the first embodiment.

Embodiment 3

[0019] The eccentric bushing 5 is arranged between the big end 16 of the main connecting rod and the connecting pin of the crankshaft 13, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com