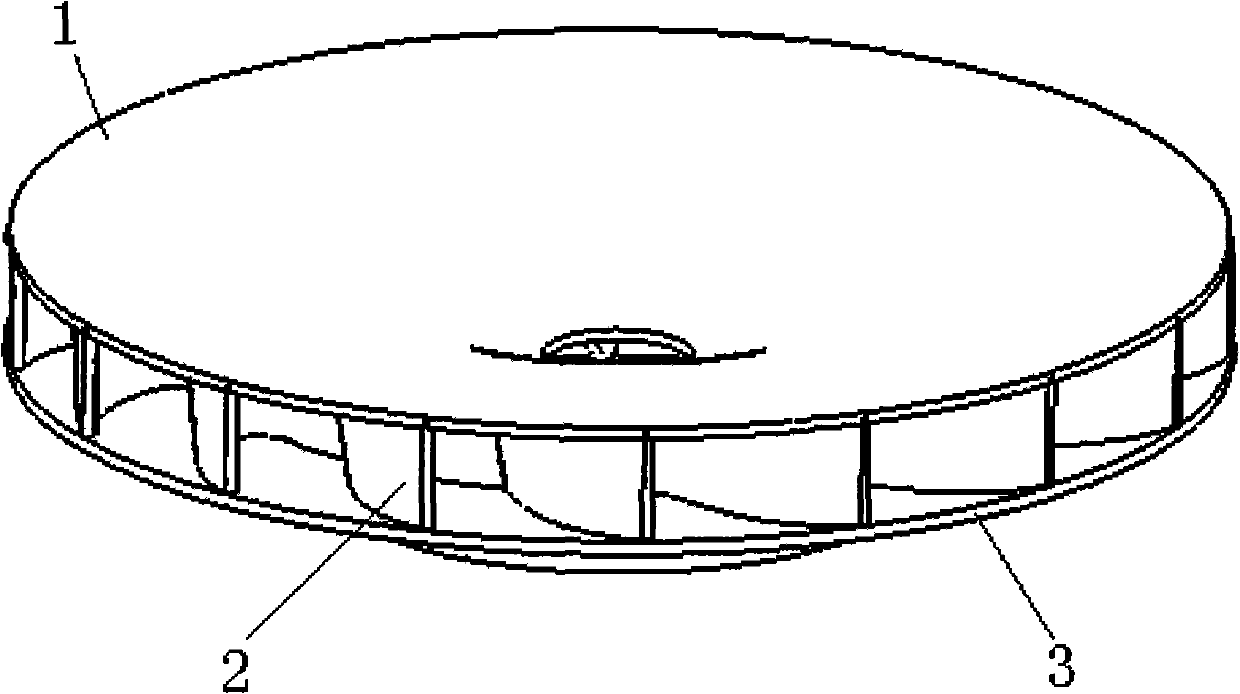

Runner used for direct connection low-speed small-scale mixed-flow turbine of hydrodynamic energy-saving cooling tower

An energy-saving, cooling tower technology, applied in the field of cooling towers, can solve the problems of easy failure, manufacturing cost, high noise, etc., and achieve the effect of simple structure, convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

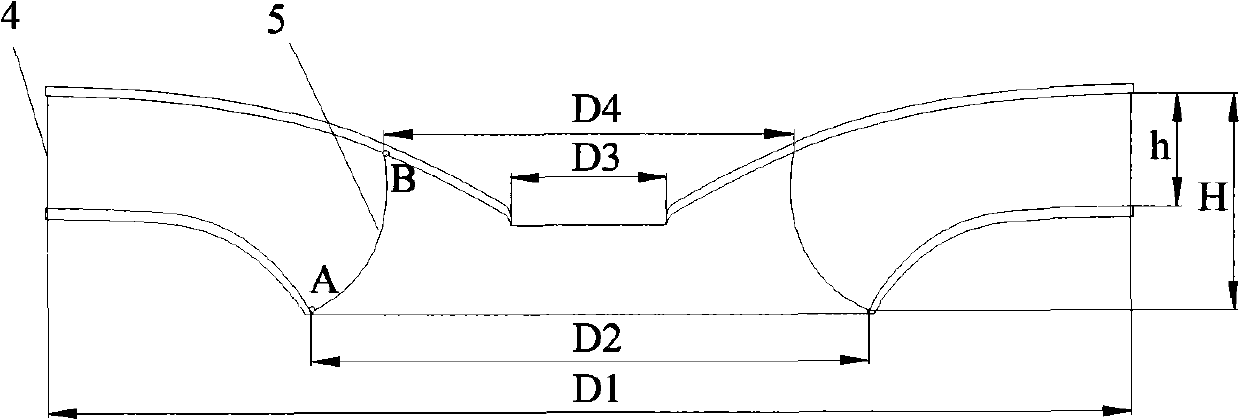

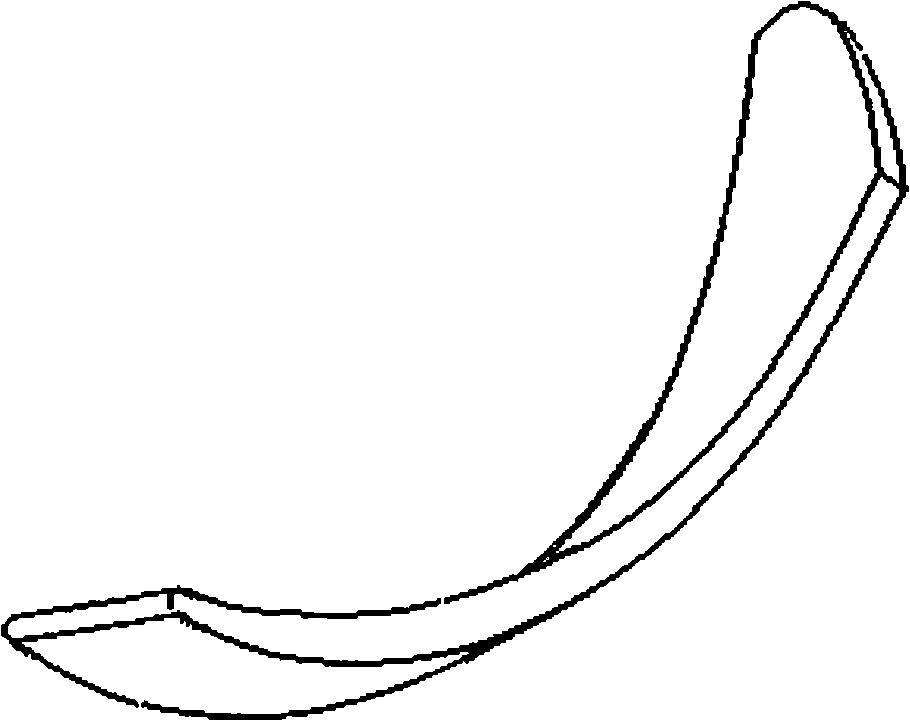

[0023] Let n11 be 35, the water pressure H entering the tower is 13m, the rated speed n of the fan blade is 136r / min, and D1 is 0.928m, and the shape of a curved blade is designed as image 3 , 4 shown. Installed and measured fan blade speed is 137r / min, in line with the design requirements.

example 2

[0025] Let n11 be 30, the water pressure H entering the tower is 15m, the rated speed n of the fan blade is 140r / min, and D1 is 0.830m, and the shape of a curved blade is designed as image 3 , 4 shown. The speed of installed and measured fan blades is 138r / min, which meets the design requirements.

example 3

[0027] Let n11 be 40, the water pressure H entering the tower is 15m, the rated speed n of the fan blade is 130r / min, and D1 is 1.192m, and the shape of a curved blade is designed as image 3 , 4 shown. Installed and measured fan blade speed is 131r / min, in line with the design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com