Method and device for drying material in vacuum

A vacuum drying and vacuum technology, which is applied in the direction of static material dryers, dry solid materials, local agitation dryers, etc., can solve the problems of easy failure of sealing devices, changes in temperature and humidity, and reduced dehumidification efficiency, and achieve dehumidification time Shortening, improved dehumidification efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

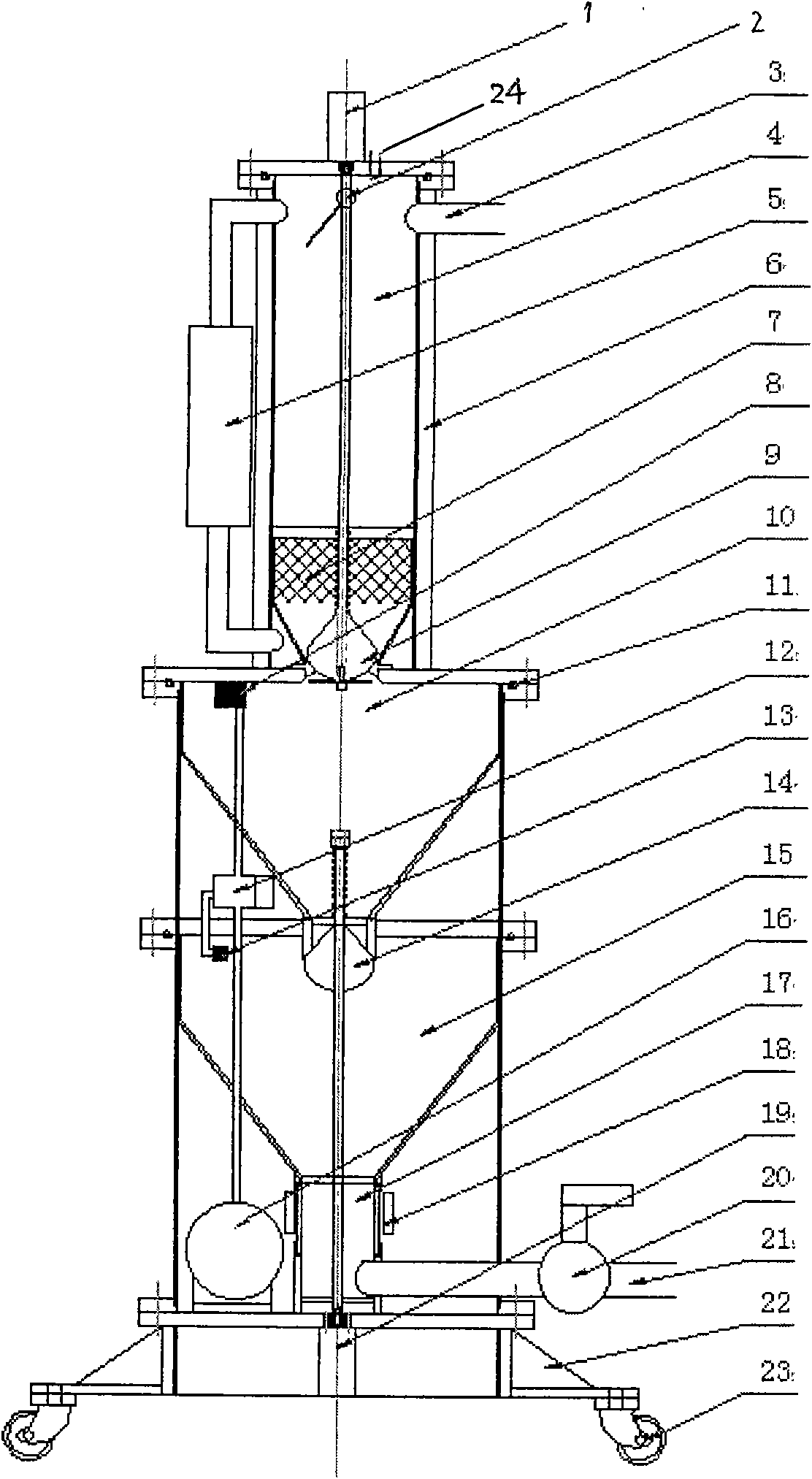

[0019] The present invention has at least two layers, which are usually formed by superimposing and closing three layers of studios. The upper studio is provided with feed valves or feeders, and the upper, middle and lower studios are equipped with upper and lower valves. When closed, each studio independently completes its own process. The upper studio is equipped with a gas heating circulation device. The device used is a hot air circulation device. A heater and a hot air duct work through the air inlet and outlet of the fan and the upper and lower connections of the upper studio to heat the materials in the upper studio. drying temperature. When the material reaches the drying temperature, the upper valve is opened and moved to the middle vacuum studio for vacuum dehumidification; the upper, middle and lower floors communicate with each other and use the valve to open or close; when the valve is closed, each studio completes its own process independently. Since the vacuum l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com