Online monitoring system and monitoring method of oilless bushing sintering production line

A monitoring system, production line technology, applied in general control system, control/regulation system, program control, etc., can solve problems such as processing loss, and achieve the effect of ensuring qualification and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

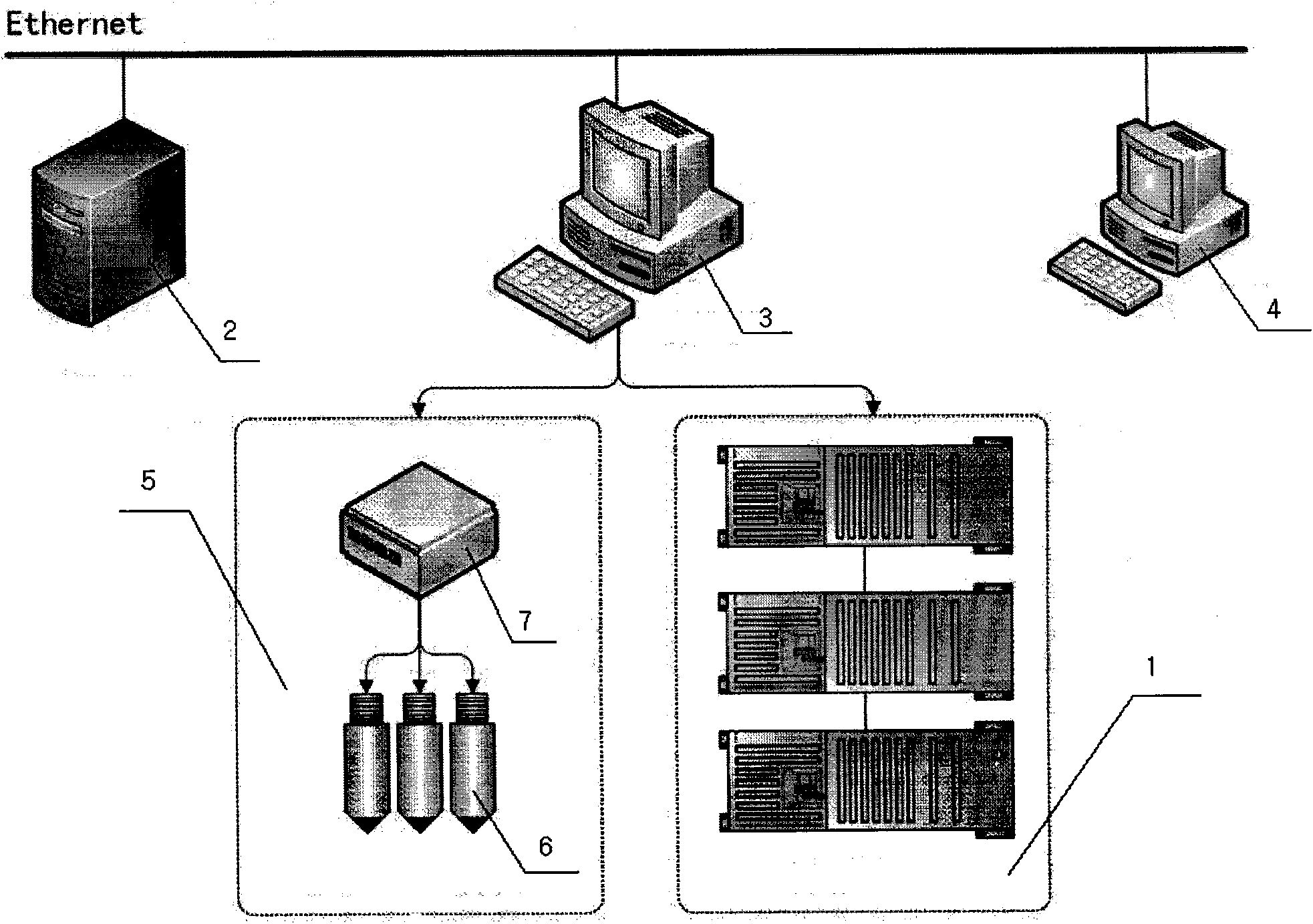

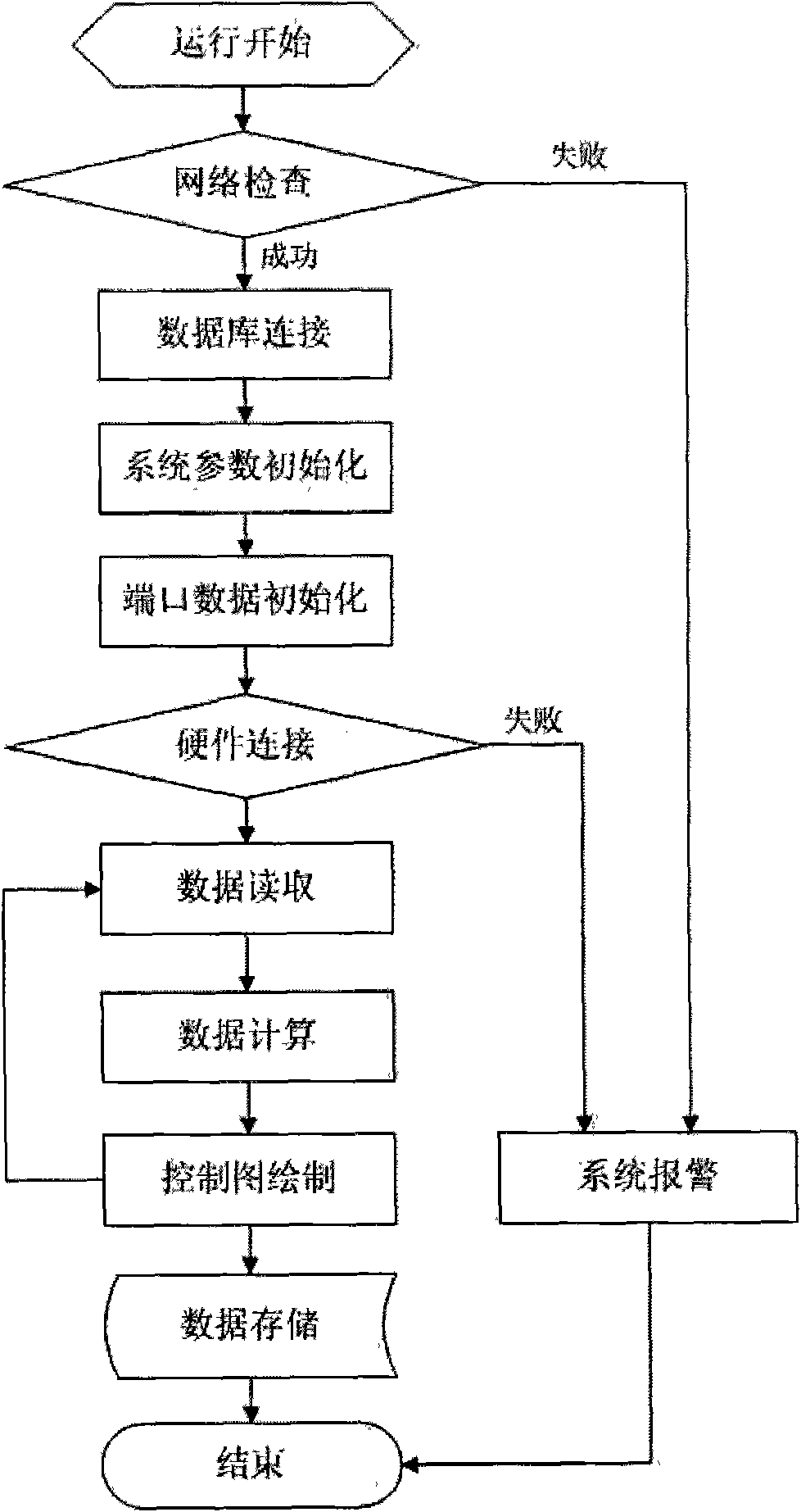

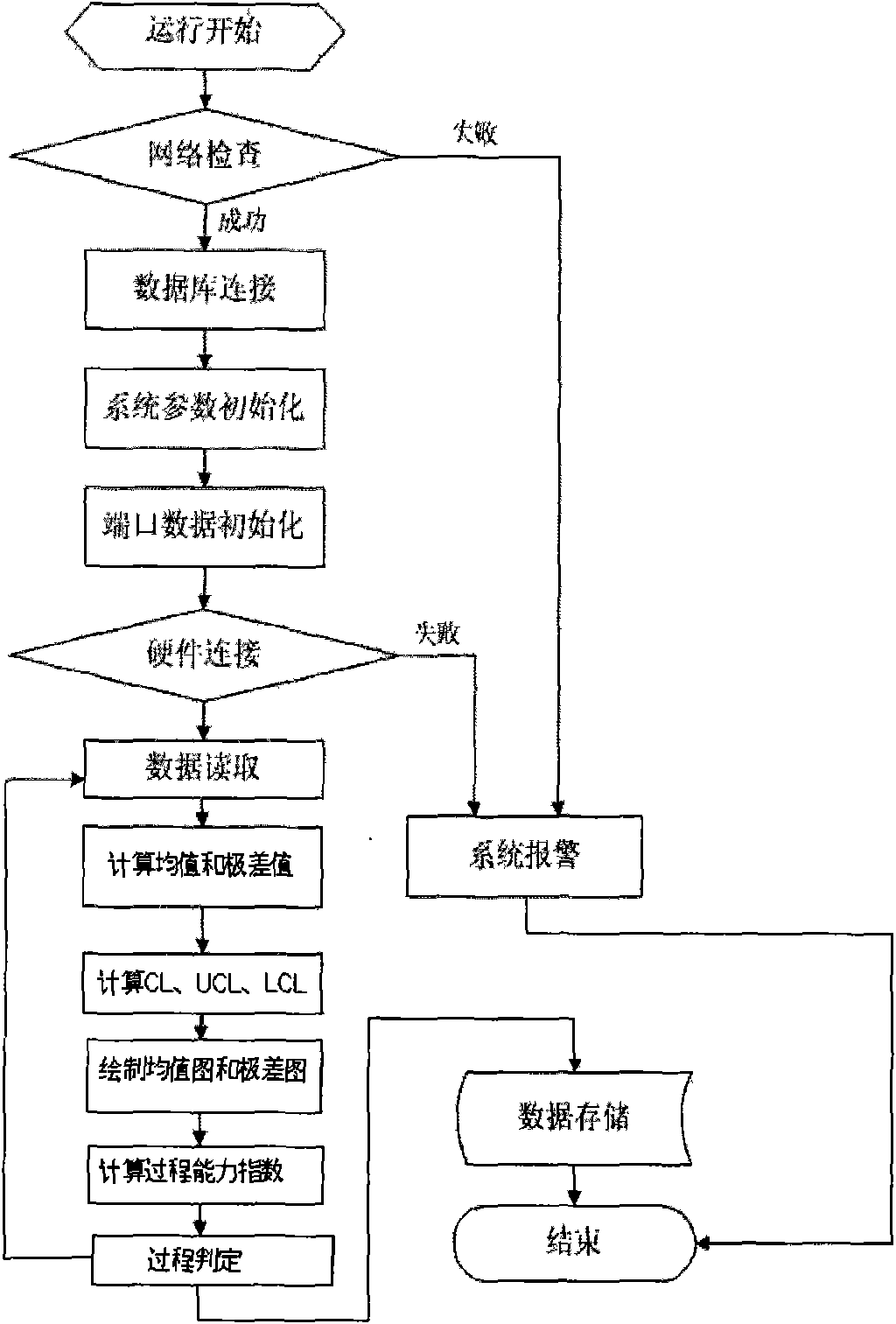

[0038] Such as figure 1 As shown, an online monitoring system for an oil-free bushing sintering production line includes a PLC 1 , a server 2 , a workstation computer 3 , a client computer 4 , and a sensor system 5 . The server 2 and the client computer 4 are connected and communicated with the workstation computer 3 through Ethernet; the server 2 is responsible for recording daily processing data, process plan data, system operator's authority and information logs, etc.; the client computer 4 The command to be operated is transmitted to the workstation computer 3, and the production line is operated in the form of a client; the sensor system 5 is composed of a sensor 6 and a converter 7, and the sensor 6 detects temperature, speed, humidity, etc. The amount is converted into digital information and transmitted to the workstation computer 3; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com