Extrusion-type walnut crusher

A shell breaker and extrusion technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of reducing product quality, easily breaking walnuts, and peculiar smell, reducing the breaking rate, improving the integrity, The effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

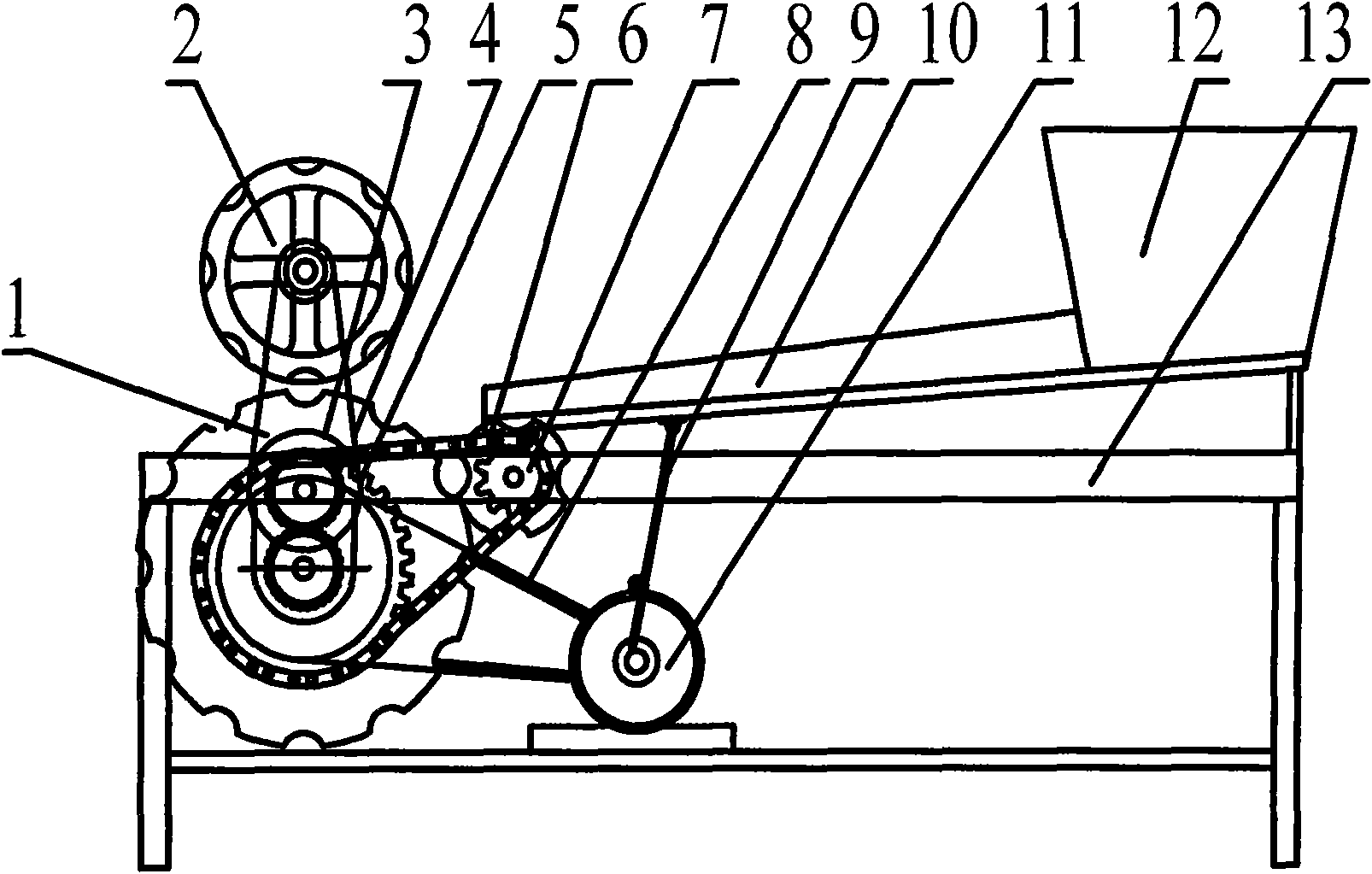

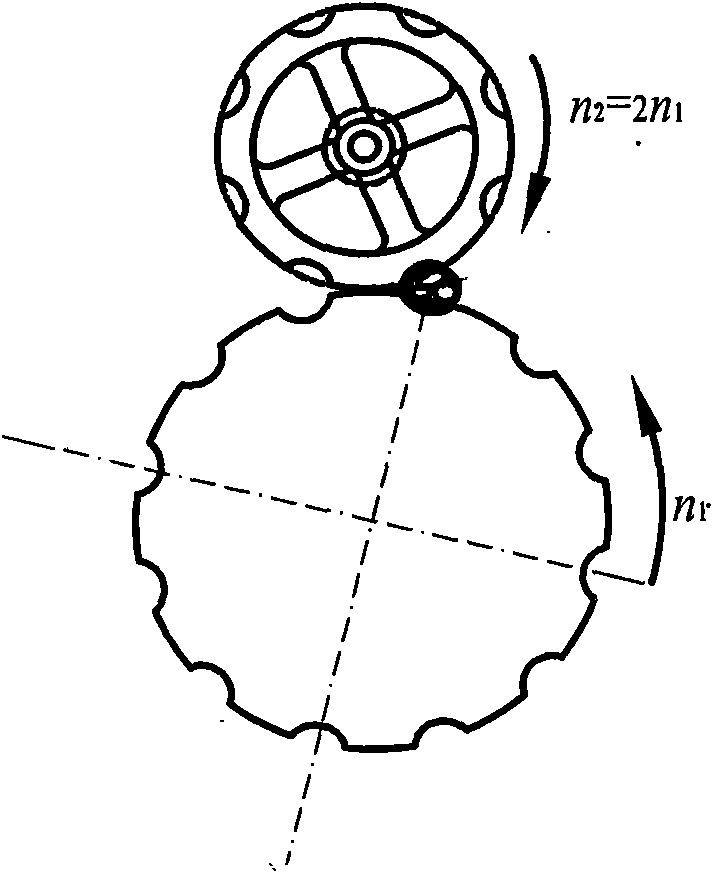

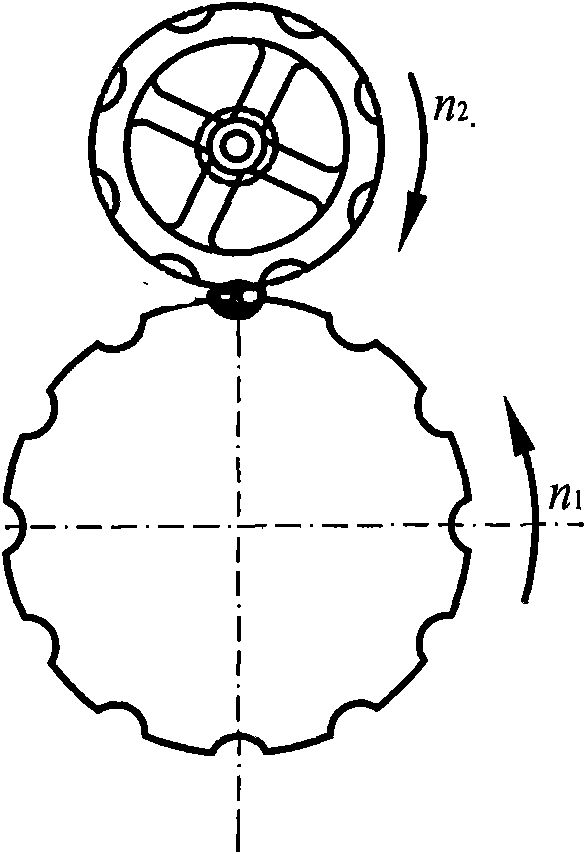

[0013] An extruding type walnut shell breaking machine, which includes a frame 13, a feed port 12 is fixed on the frame, the feed port is connected with a conveying ramp 10, and the front part of the frame has an extrusion wheel, a main working wheel 1, an extrusion The two-speed extrusion shell breaking device composed of the high-speed wheel 2 and the reverse power transmission wheel 3, the high-speed wheel 2 of the extrusion wheel and the reverse power transmission wheel 3 are connected by a transmission chain 4, and the main working wheel 1 of the extrusion wheel is Drive wheel sprocket 5 is arranged, and drive wheel sprocket is connected with feed wheel 7 by transmission chain 6, also has motor 11 on the frame 13, and feeding vibration connecting rod 9 is connected with feed wheel 7 on the motor.

[0014] The front part of the frame 13 is provided with a two-speed extruding shell breaking device consisting of the main working wheel 1 of the extrusion wheel, the high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com