New mean production control type threshing and redrying method

A technology for threshing and redrying and production control, which is applied in the fields of tobacco preparation, test sample preparation, food science, etc. It can solve the problem of uncontrollable internal chemical composition of tobacco leaves, and achieve average management, stable quality, and improved processing. horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

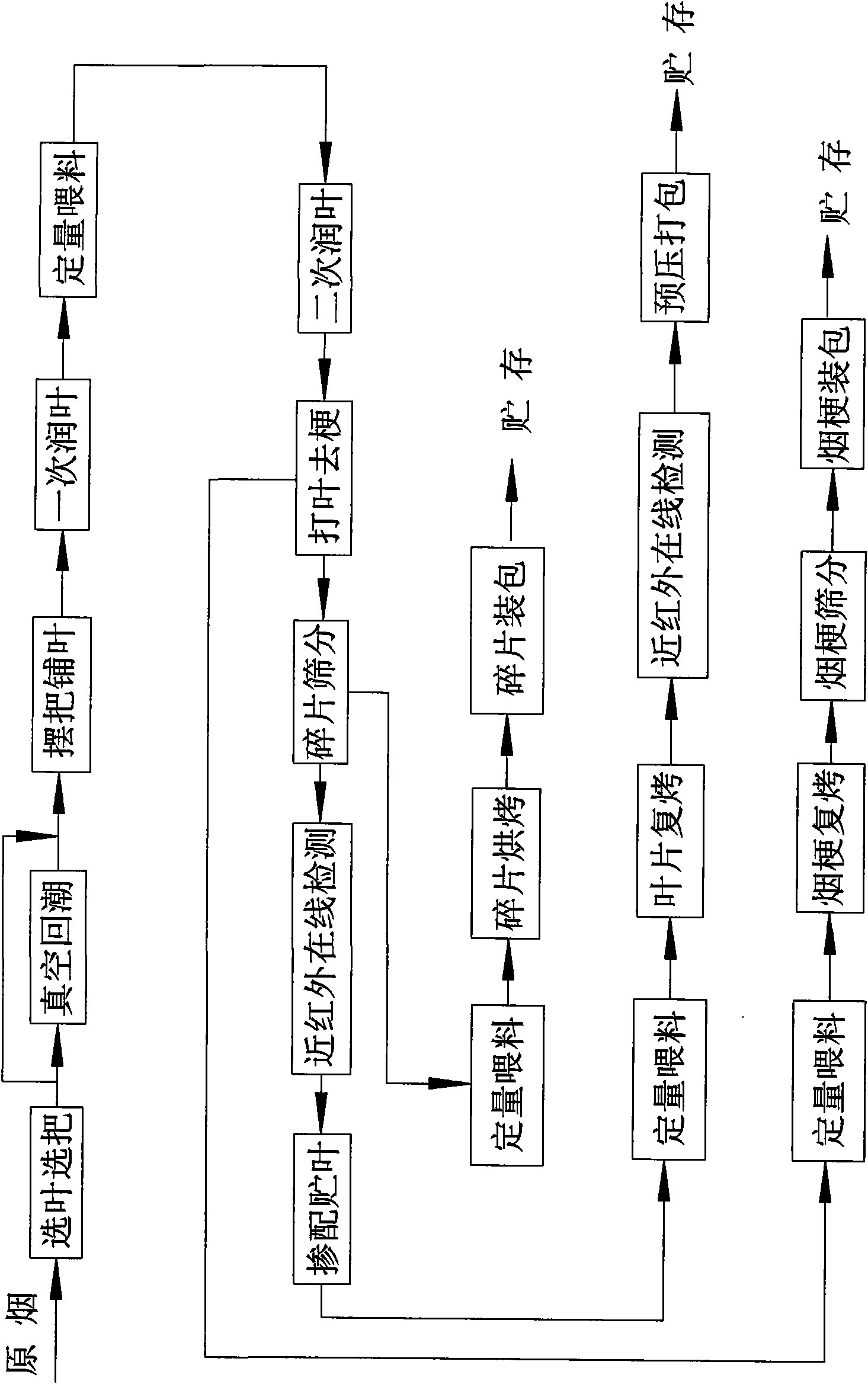

[0042] Example 1: A new method of equalized production control type leaf threshing and re-roasting

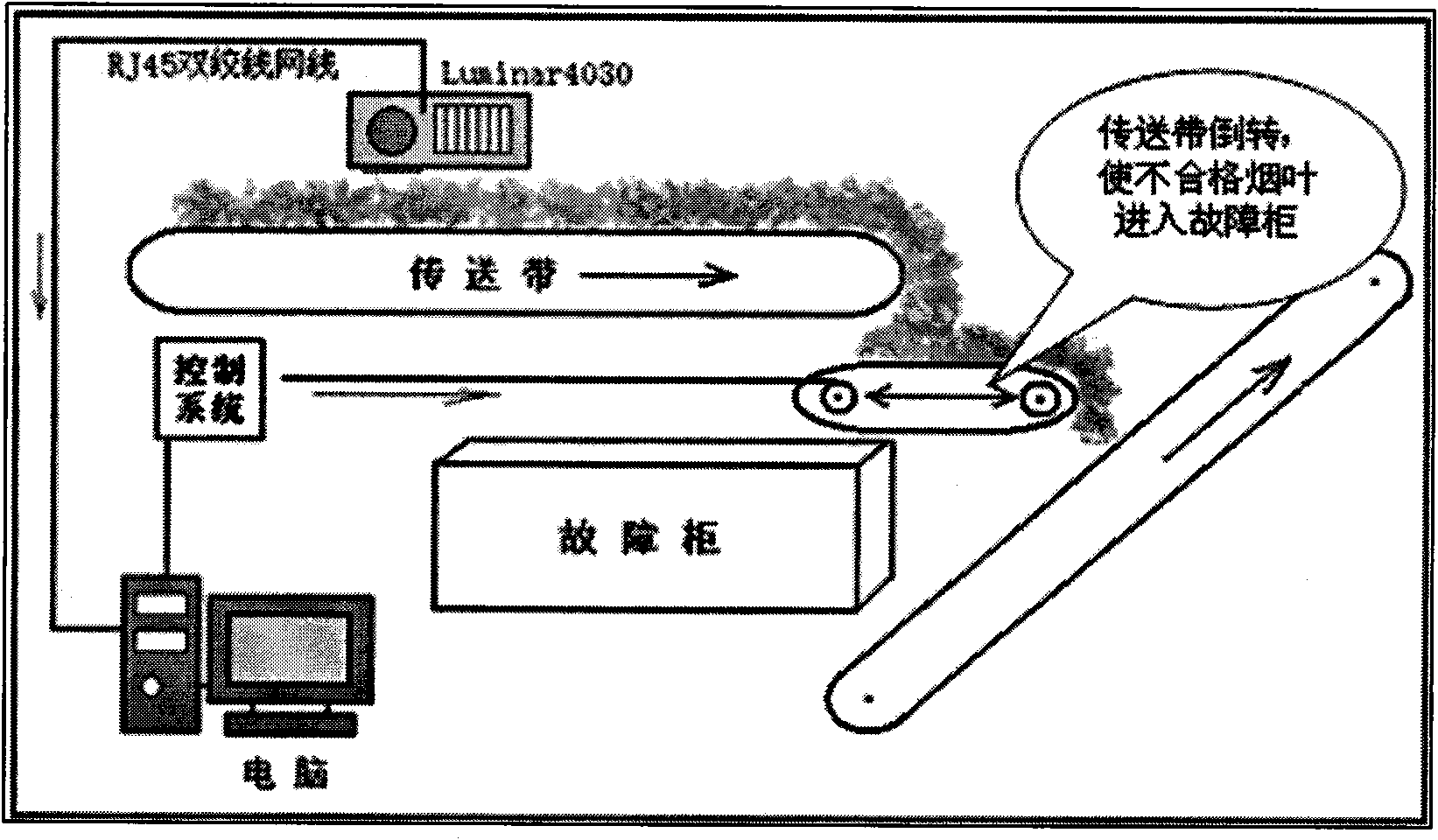

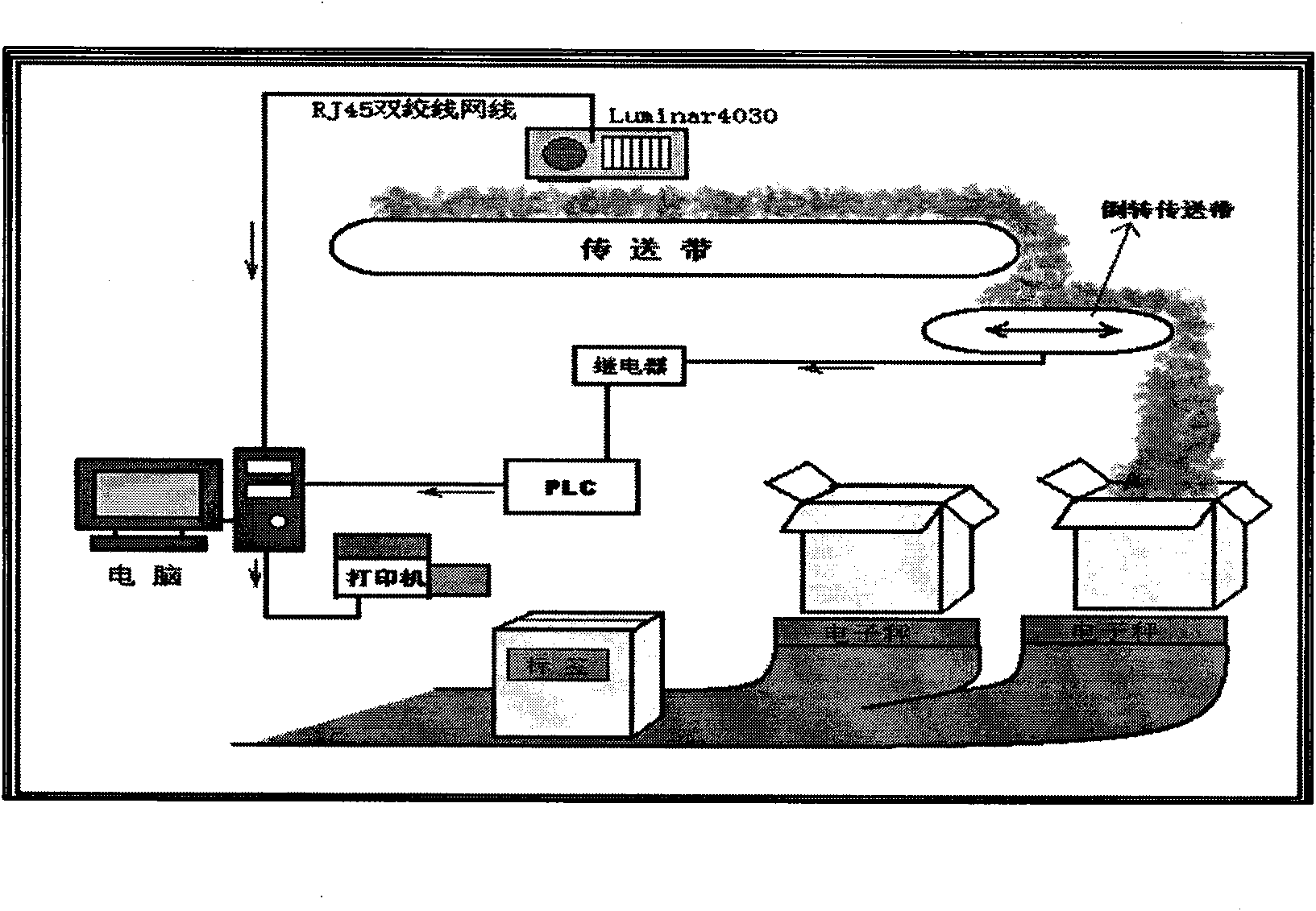

[0043] The near-infrared spectrometer used in the present invention is the Luminar4030 type AOTF near-infrared spectrometer produced by the U.S. BRIMROSE company.

[0044] The relevant parameters of the online detection of the near-infrared spectrometer before rebaking are: the spectral range of the near-infrared spectrometer is 1100-2300nm, the wavelength increment is 2.0nm, the average number of scans is 200, the data format is transmittance, and the scan mode is ratio mode.

[0045] The parameters related to the online detection of the near-infrared spectrometer after rebaking are: the spectral range of the near-infrared spectrometer is 1100-2300nm, the wavelength increment is 2.0nm, the average number of scans is 1000, the data format is transmittance, and the scan mode is ratio mode.

[0046] The near-infrared online detection of the chemical composition of leaves is nicot...

Embodiment 2

[0052] Embodiment two: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0053] The raw material is the middle tobacco leaves, and the flow rate of the tobacco leaves on the conveyor belt is 8000kg / h.

Embodiment 3

[0054] Embodiment three: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0055] The raw material is the lower tobacco leaves, and the flow rate of the tobacco leaves on the conveyor belt is 7000kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com