Method for synchronously reclaiming orthophosphorous acid and glyphosate in glyphosate production wastewater by chemical precipitation method

A chemical precipitation method, a technology for producing wastewater, applied in the field of chemical technology, can solve problems such as difficult recycling and treatment, large volume of wastewater, and high concentration of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

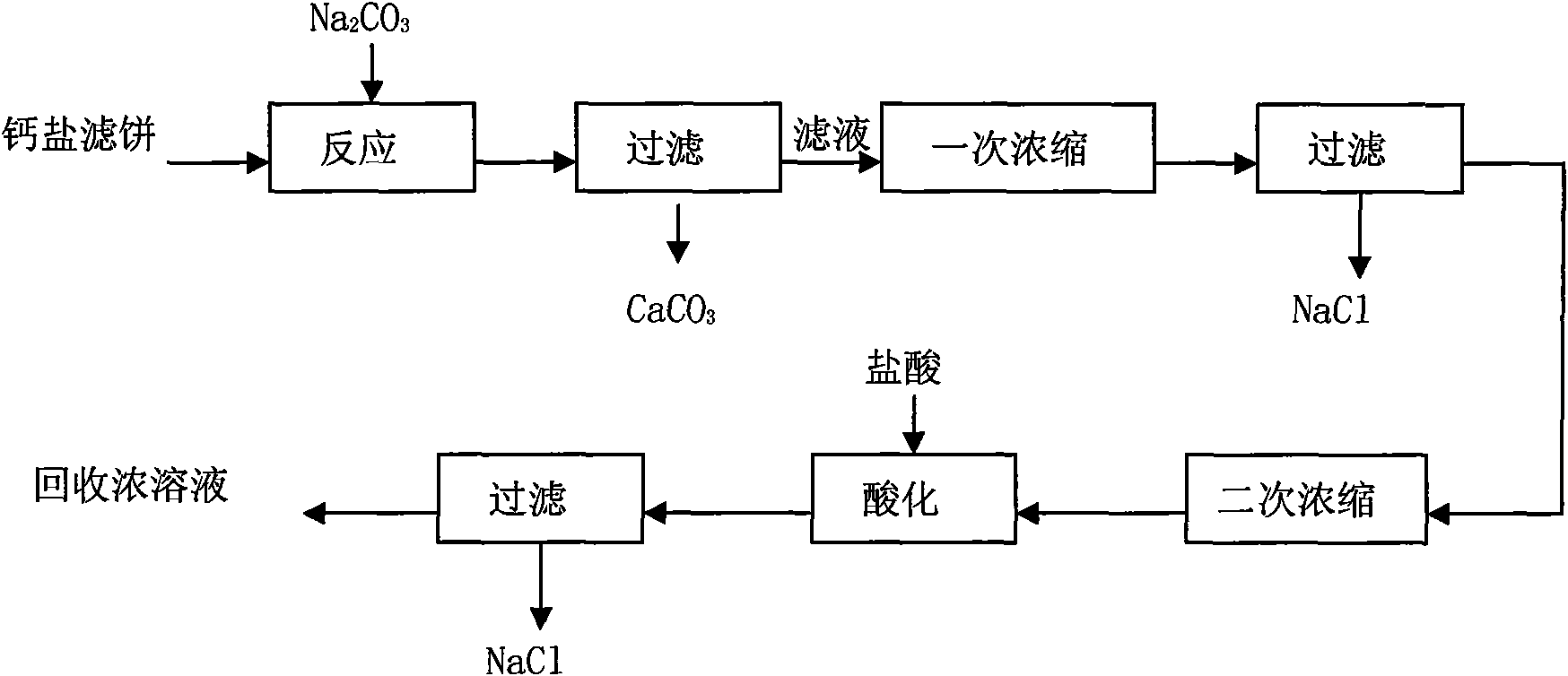

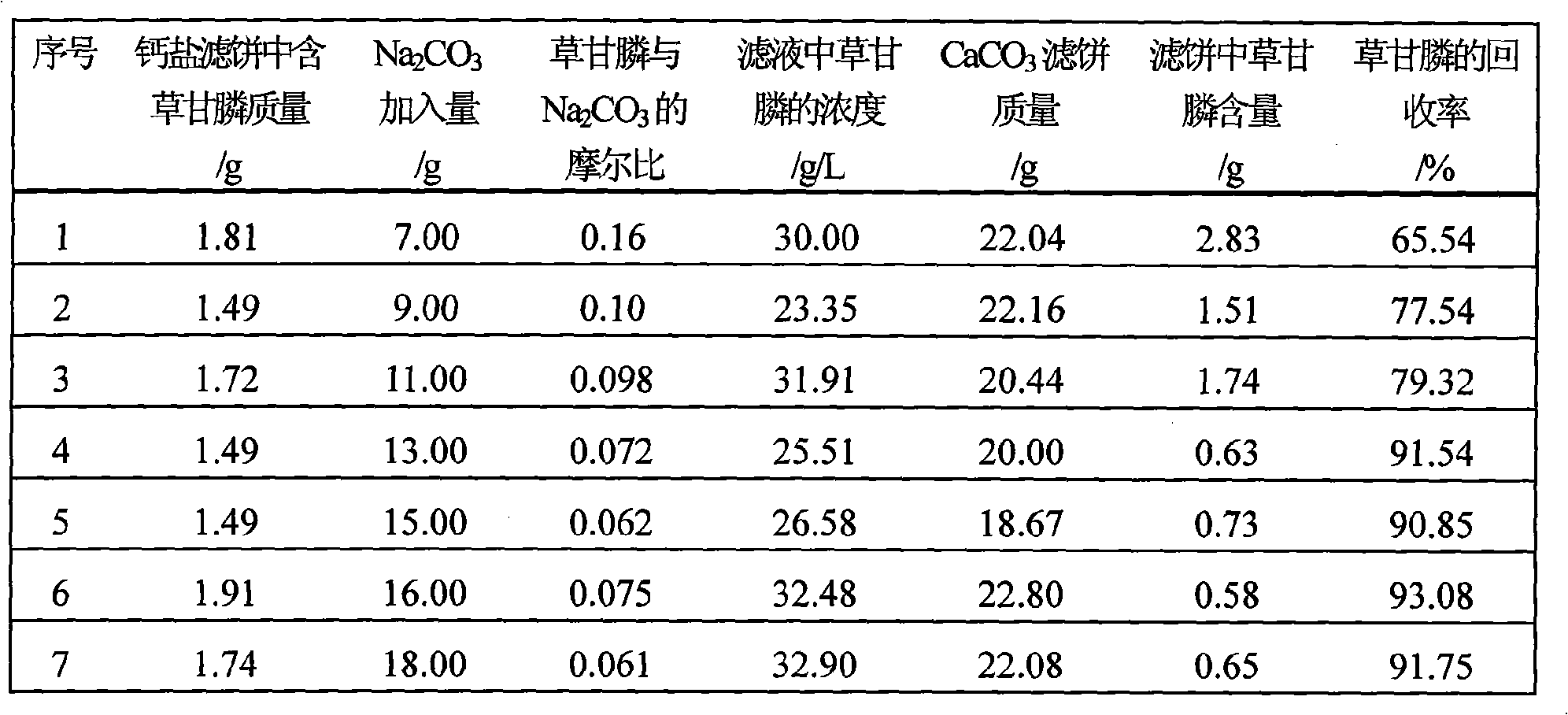

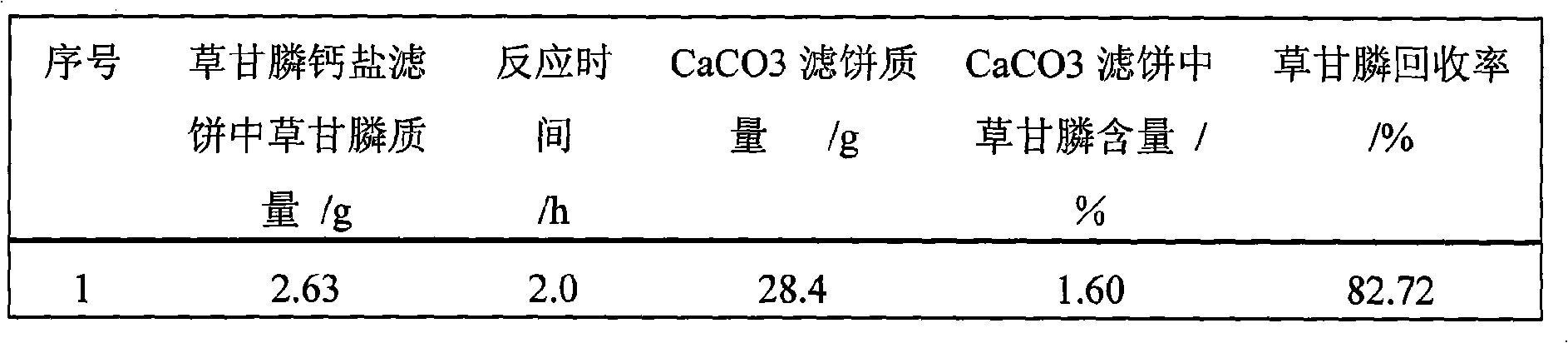

[0046] Embodiment 1, chemical precipitation method reclaims the method for phosphorous acid and glyphosate in glyphosate production waste water simultaneously, with reference to figure 1 , the pH value of glyphosate production wastewater was adjusted to 10.5. Ca 2+ Treatment (by adding CaCl 2 The concentration of solution is 634g / L and add-on is the calcium salt filter cake that obtains after 22ml / 100ml former waste water), adds Na 2 CO 3 The reaction separates out CaCO 3 precipitation, when the added Na 2 CO 3 The amount is glyphosate and Na in calcium salt filter cake 2 CO 3 When the molar ratio is 0.06~0.075, the recovery rate of glyphosate is greater than 90%, and when the molar ratio is 0.075, the recovery rate of glyphosate is 93.08%; when the reaction time is more than 4h, the recovery rate of glyphosate reaches 93%. % or more, wherein when the reaction time was 17h, the recovery rate was 94.3%.

[0047] Separation of CaCO 3 The final filter cake is concentrat...

Embodiment 2

[0050] Embodiment 2 is basically the same as Embodiment 1, but has the following changes: in the (3) step, the glyphosate and Na 2 CO 3 The molar ratio is 0.16.

Embodiment 3

[0051] Embodiment 3 is basically the same as Embodiment 1, but has the following changes: in the (3) step, the glyphosate and Na 2 CO 3 The molar ratio is 0.061.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com