Method for producing zinc powder and reclaiming scattered metals indium and germanium by distilling aluminum hard zinc in vacuum

A technology of scattered metals and hard zinc, applied in the field of vacuum metallurgy of non-ferrous metals, to achieve effective utilization and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

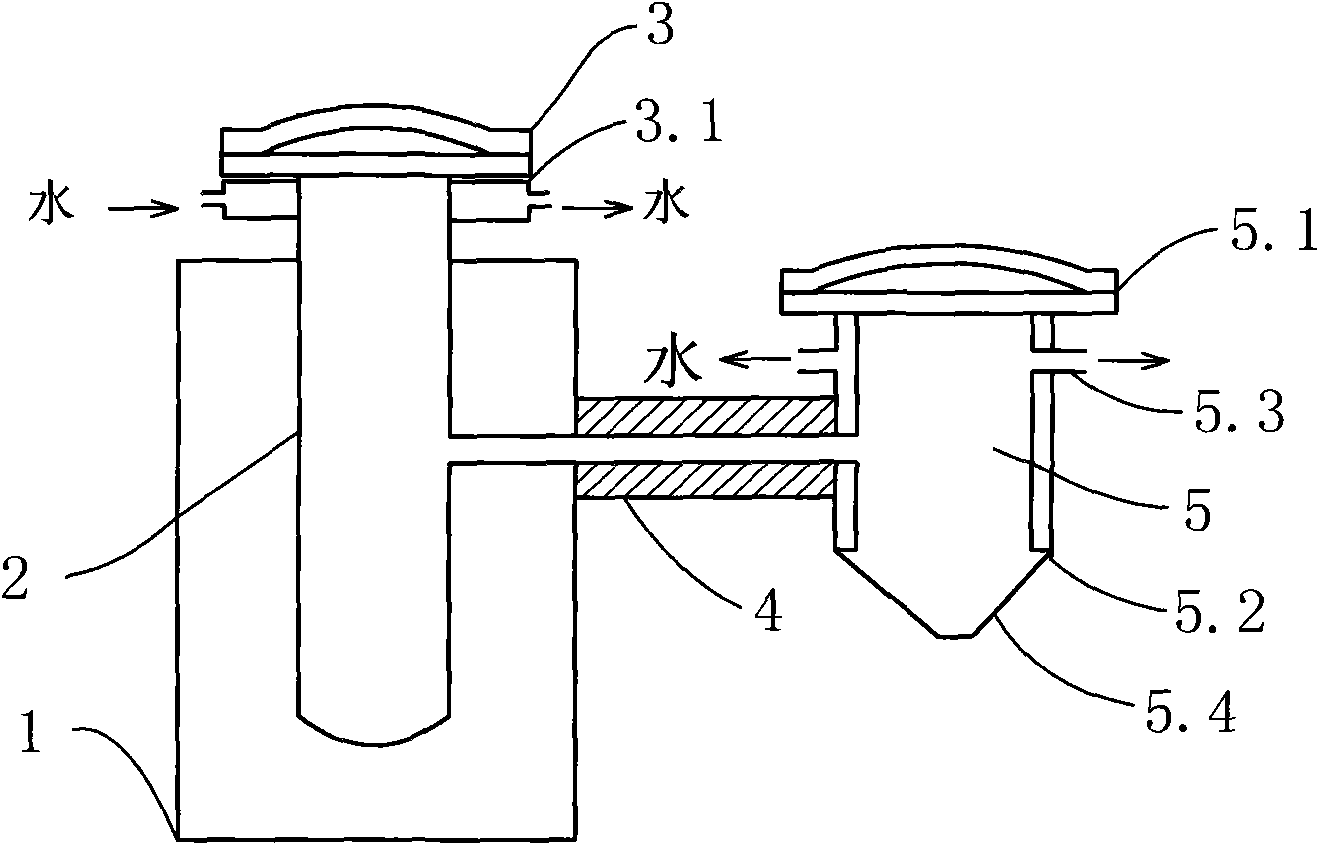

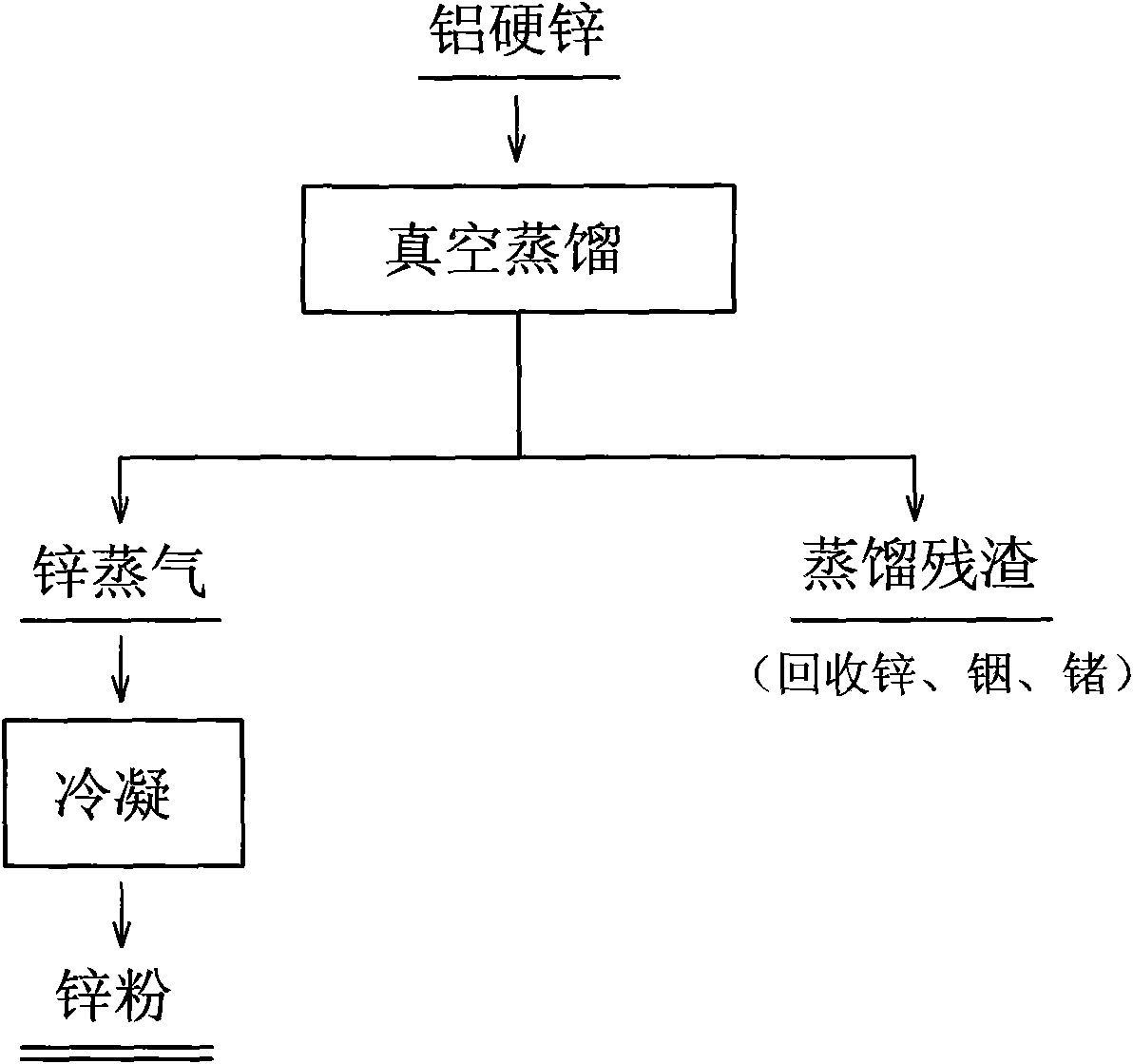

Embodiment 1

[0021] Get 1000Kg aluminum hard zinc raw material, containing aluminum 10%, iron 15%, indium 0.35%, lead 5%, germanium 0.11%, zinc balance. Put it into the distillation tank through a crane and a feeder, cover the sealing cover, connect the vacuum pump through the exhaust pipe, and carry out vacuuming. When the pressure in the distillation tank reaches 10Pa, turn on the power supply of the heater to heat the heater; the distillation tank passes through 2.2 hours of heating to make the temperature reach 850°C, and then keep the constant temperature for 8 hours. When the vacuum degree is maintained at about 10Pa, when the temperature is cooled to 200°C, turn off the vacuum pump and the cooling water in the condenser water jacket. water, open the sealing lid of the retort, and take out 398.28Kg of residues containing zinc and scattered metal indium and germanium. Release 601.71Kg of zinc powder from the discharge port of the condenser.

Embodiment 2

[0023] Get 1000Kg aluminum hard zinc raw material, containing aluminum 5%, iron 10%, indium 0.2%, lead 2%, germanium 0.02%, zinc surplus. Put it into the distillation tank via a crane and a feeder, cover the sealing cover, connect the vacuum pump through the exhaust pipe, and carry out vacuuming. When the pressure in the distillation tank reaches 15Pa, turn on the power supply of the heater to heat up the heater; the distillation tank passes through 3.2 h heating, the temperature reaches 950°C, and the constant temperature is kept for 8 hours. When the vacuum degree is maintained at about 8Pa, cool down to 200°C, turn off the cooling water in the vacuum pump and condenser water jacket, and open the distillation tank. Seal the lid, take out the residue containing zinc and scattered metal indium and germanium, the weight is 289.65Kg. Open the discharge port of the condenser, and release 710.32Kg of zinc powder from the discharge port of the condenser.

Embodiment 3

[0025] Get 1000Kg aluminum hard zinc raw material, containing aluminum 15%, iron 20%, indium 0.5%, lead 8%, germanium 0.2%, zinc balance. Put it into the distillation tank via a crane and a feeder, cover the sealing cover, connect the vacuum pump through the exhaust pipe, and carry out vacuuming. When the pressure in the distillation tank reaches 15Pa, turn on the power supply of the heater to heat up the heater; the distillation tank passes through 3.2 Heating for h, the temperature reaches 1000°C, and the constant temperature is kept for 8 hours. When the vacuum degree is maintained at about 8Pa, cool down to 200°C, turn off the cooling water in the vacuum pump and condenser water jacket, and open the distillation tank. Seal the lid, take out the residue containing zinc and scattered metal indium and germanium, the weight is 517.43Kg. Open the discharge port of the condenser, and release 482.55Kg of zinc powder from the discharge port of the condenser.

[0026] The direct y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com