Gold alloy with 18k span effect and preparation method thereof

An alloy and effect technology, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of time-consuming, energy-consuming, cumbersome heat treatment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

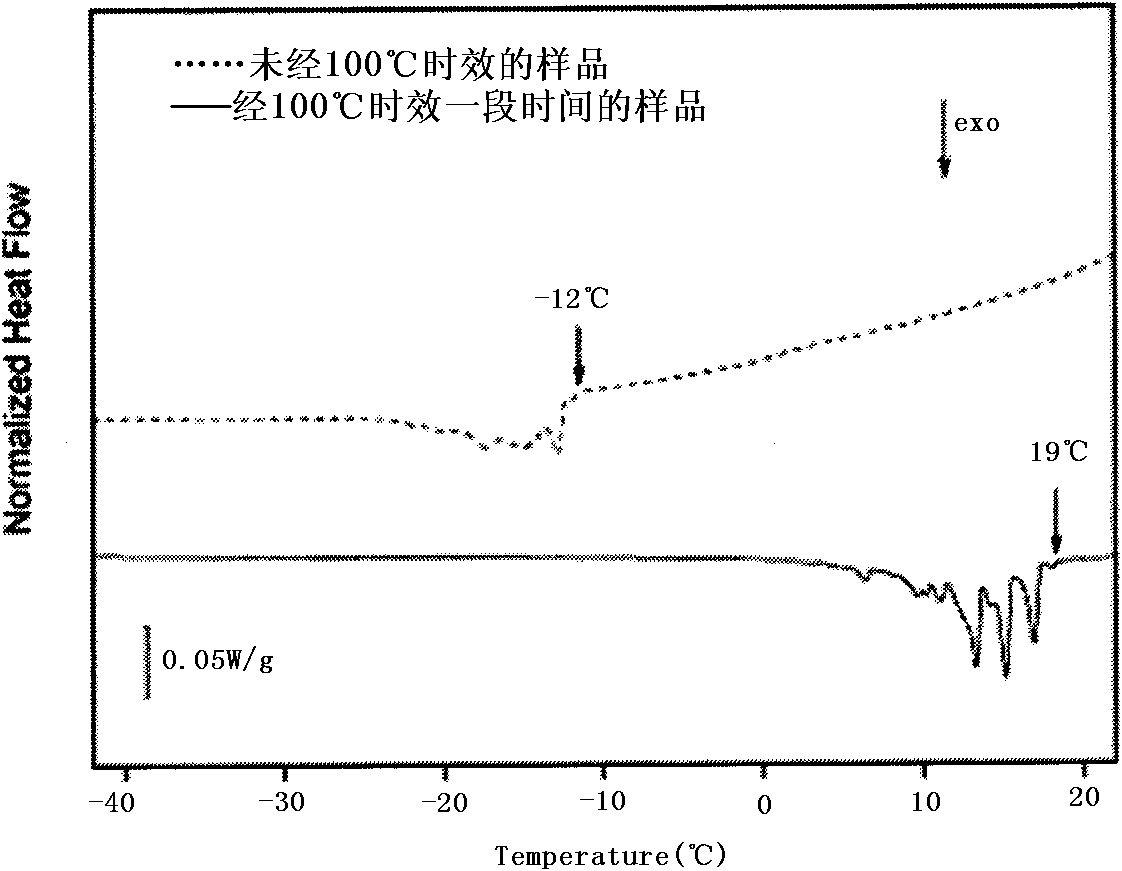

[0022] Embodiment 1: Preparation of a gold alloy containing 18k gold and having the Spawn effect, its composition and mass percentage are: Au 75.00%, Cu 19.01% and Al 5.99%.

[0023] The gold alloy with 18K Spank effect described in this embodiment is prepared through the following steps:

[0024] The first step is to select 99.9% pure gold, 99.9% pure copper, and 99.9% pure aluminum, and carry out batching according to the weight percentage of Au:Cu:Al=75:19.01:5.99; then under the protection of inert gas, the batching is vacuum smelted , to obtain a gold alloy casting slab, and finally perform annealing treatment in a vacuum environment, the annealing temperature is 600 ° C, and the time is 5 hours;

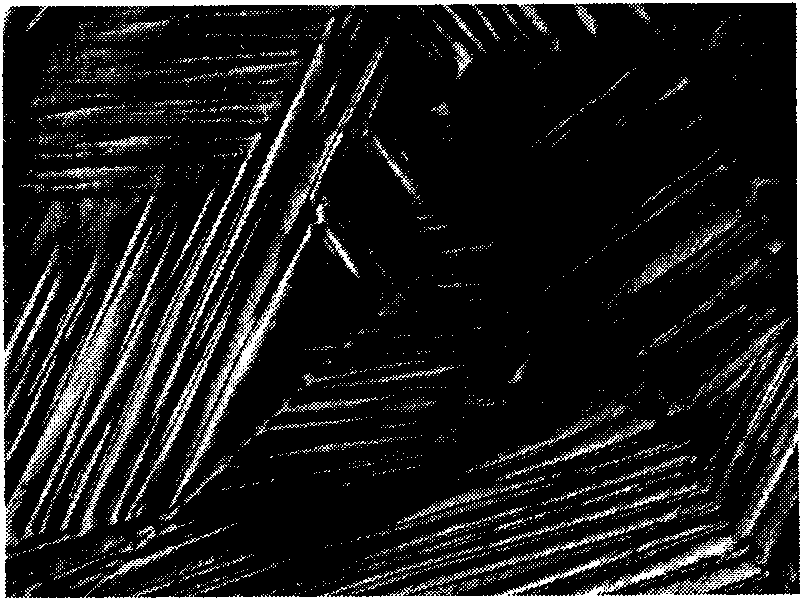

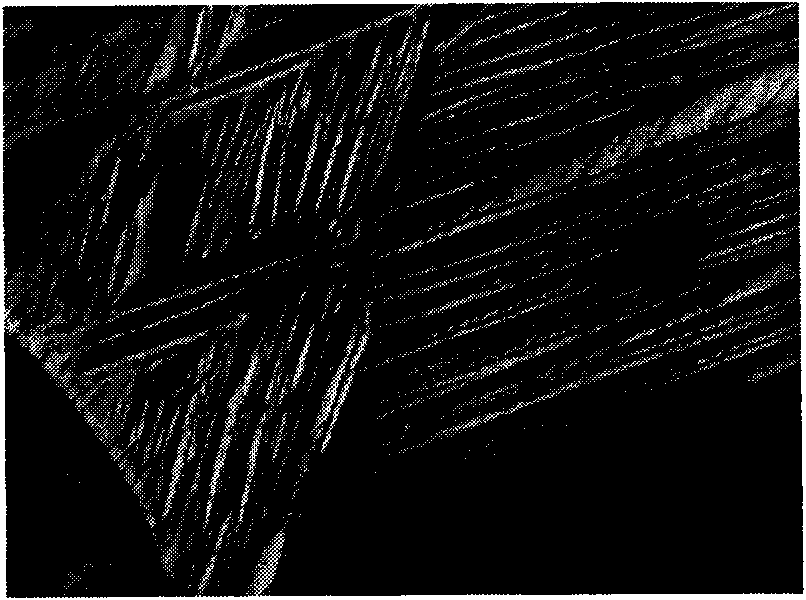

[0025] The second step is to melt the gold alloy casting slab and cast it into the designed model to obtain alloy castings; then perform mechanical polishing on the alloy castings in turn to obtain a smooth surface; then heat to 680°C under vacuum protection, Keeping the tempe...

Embodiment 2

[0028] Embodiment 2: Preparation of a gold alloy containing 18k gold and having the Spawn effect, its composition and mass percentage are: Au 81.21%, Cu 14.47%, Al 4.32%.

[0029] The gold alloy with 18K Spank effect described in this embodiment is specifically prepared through the following steps:

[0030] The first step is to select 99.9% pure gold, 99.9% pure copper, 99.9% pure aluminum, Au: Cu: Al = 81.21: 14.47: 4.32 weight percentage for batching; then under the protection of inert gas, the batching is vacuum smelted, The gold alloy casting slab was obtained, and finally annealed in a vacuum environment at a temperature of 600° C. for 4 hours.

[0031] The second step is to melt the gold alloy casting billet and cast it into the designed model to obtain alloy castings, then heat the alloy castings to 680°C under vacuum protection in turn, and heat the alloy castings with normal temperature pure water after 30 minutes After quenching and finally chemical polishing, the a...

Embodiment 3

[0034] Example 3: Preparation of a gold alloy containing 18k gold and having the Spawn effect, its composition and mass percentage are: Au 82.00%, Cu 13.10% and Al 4.90%.

[0035] The gold alloy with 18K Spank effect described in this embodiment is prepared through the following steps:

[0036] The first step is to select 99.9% pure gold, 99.9% pure copper, and 99.9% pure aluminum, and carry out batching according to the weight percentage of Au:Cu:Al=82:13.10:4.90; then under the protection of inert gas, the batching is vacuum smelted , to obtain a gold alloy casting slab, and finally perform annealing treatment in a vacuum environment, the annealing temperature is 600 ° C, and the time is 5 hours;

[0037] The second step is to melt the gold alloy casting slab and cast it into the designed model to obtain alloy castings; then perform mechanical polishing on the alloy castings in turn to obtain a smooth surface; then heat to 680°C under vacuum protection, Keeping the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| martensitic transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com