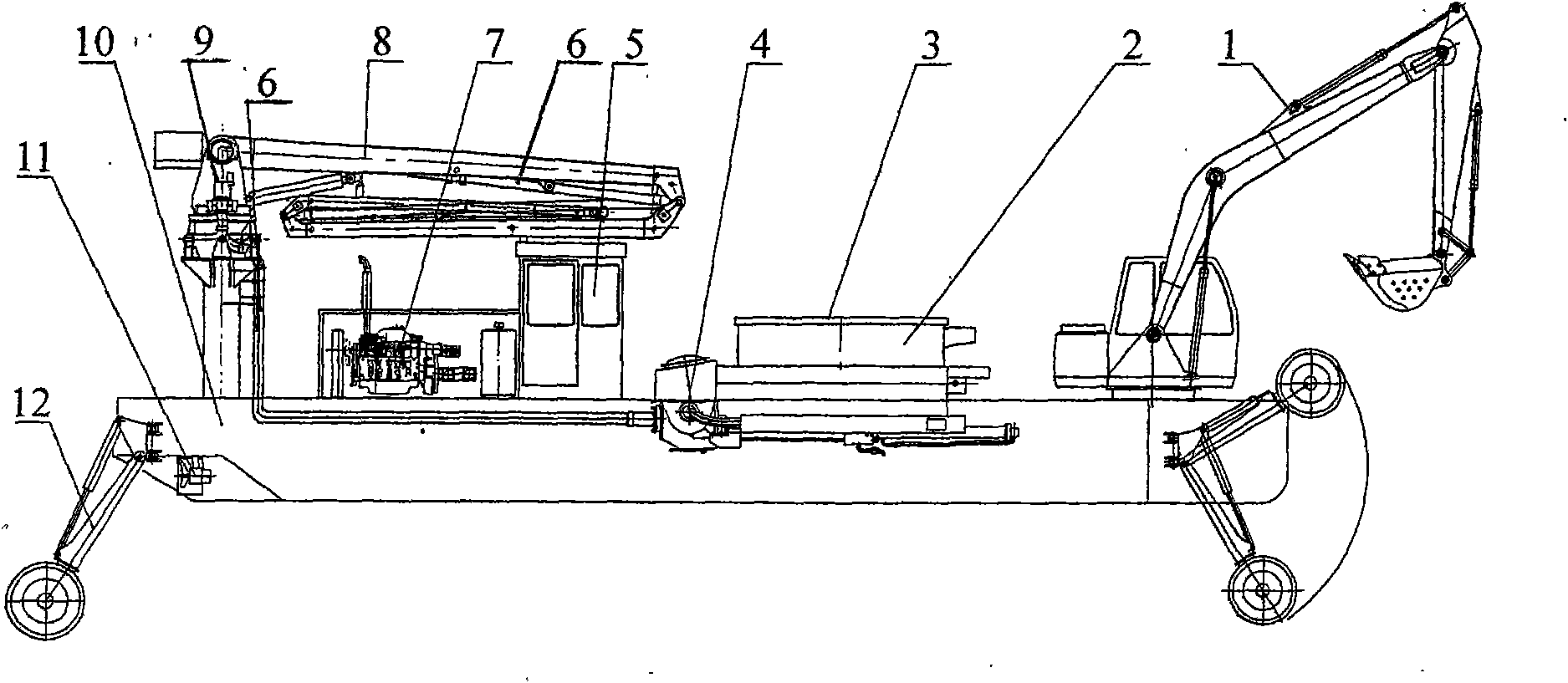

Turtle type pump dredge

A pumping and sea turtle technology, which is applied to special-purpose ships, earth movers/excavators, ships, etc., can solve the problems of inability to handle domestic and industrial waste, low mud concentration, secondary pollution, etc., and achieve simple structure, The effect of large cylinder diameter and reduced precipitation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

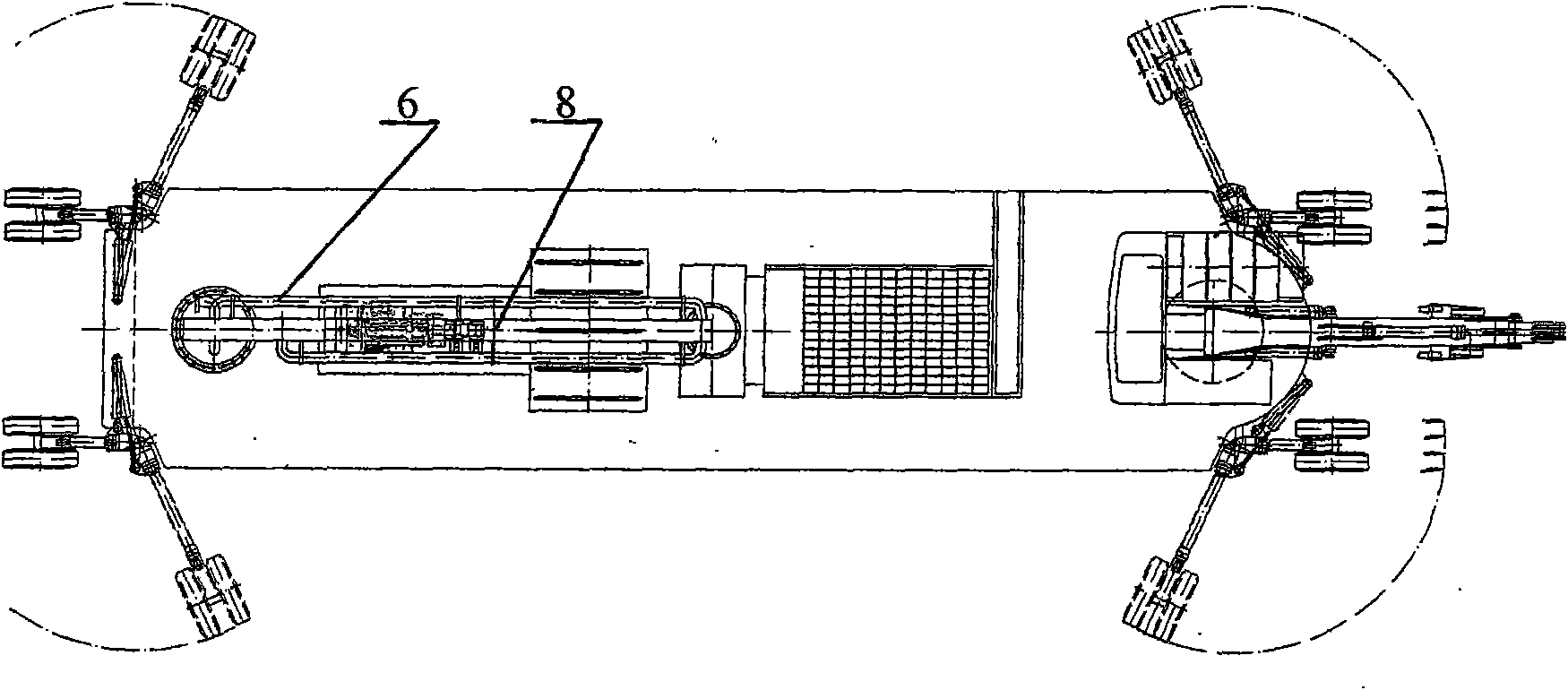

[0011] The outriggers are hinged on the four corners of the hull, and each outrigger is connected to the hull with a horizontal oil cylinder and an outrigger oil cylinder, and the movement of the horizontal oil cylinder and the outrigger oil cylinder pushes the hull to crawl and shift on land. The double propeller is installed at the stern of the ship. It can sail freely in the water by the propeller. During operation, the ship can be propped up by the outriggers to ensure the stability of the entire ship. The positive displacement mud pump is installed in the middle of the vehicle, with a theoretical pumping pressure of 7-10Mpa and a theoretical mud conveying capacity of 70-100 cubic meters per hour. A 360°rotating platform is fixed on the support of the cloth machine, and one end of the first section of the hinged folding support arm is attached to the platform. A hydraulic connecting rod is connected between the first section support arm and the rotating platform. The support a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com