Multi-ribbed composite wallboard outer insulation integrated technology and construction process thereof

A composite wallboard and construction technology technology, applied in the direction of walls, building components, buildings, etc., can solve the problem that the external insulation and composite wallboards are prone to void, separation, increase the workload of external insulation and maintenance of the wall, and the construction quality is difficult to be effective. Guarantee and other issues, to achieve the effect of reducing the amount of maintenance work in the later period, reducing the amount of high-altitude work, and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention provides an integrated technology of external thermal insulation of dense-ribbed composite exterior wall panels and its construction process. The invention will be further described in detail through the description of drawings and specific implementation methods below.

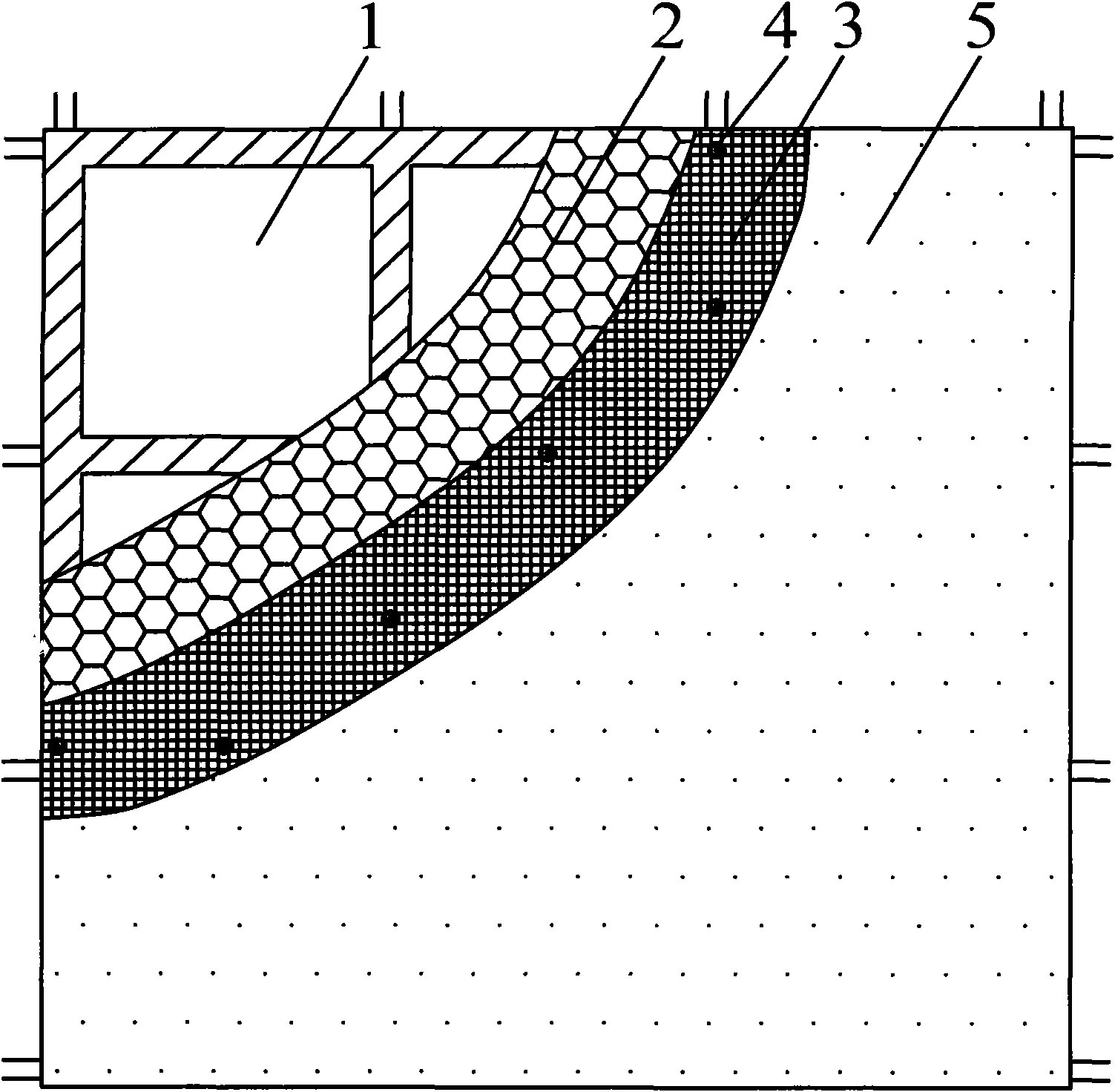

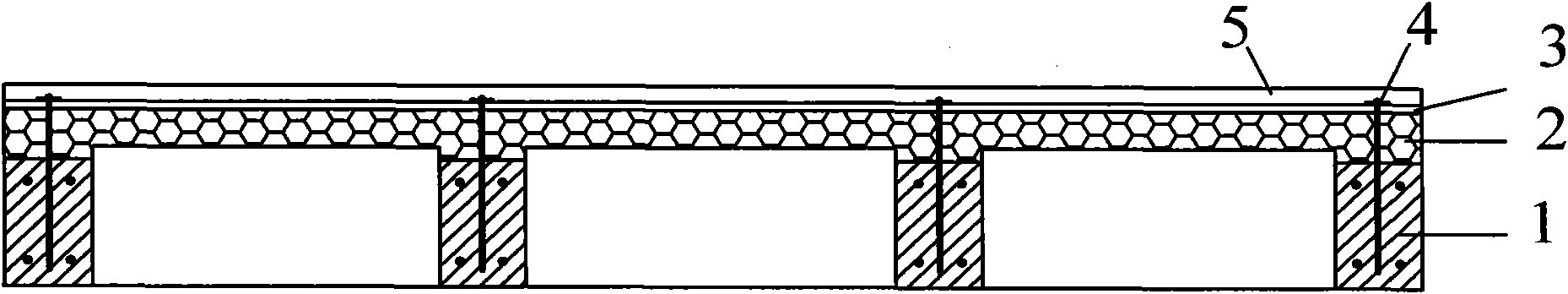

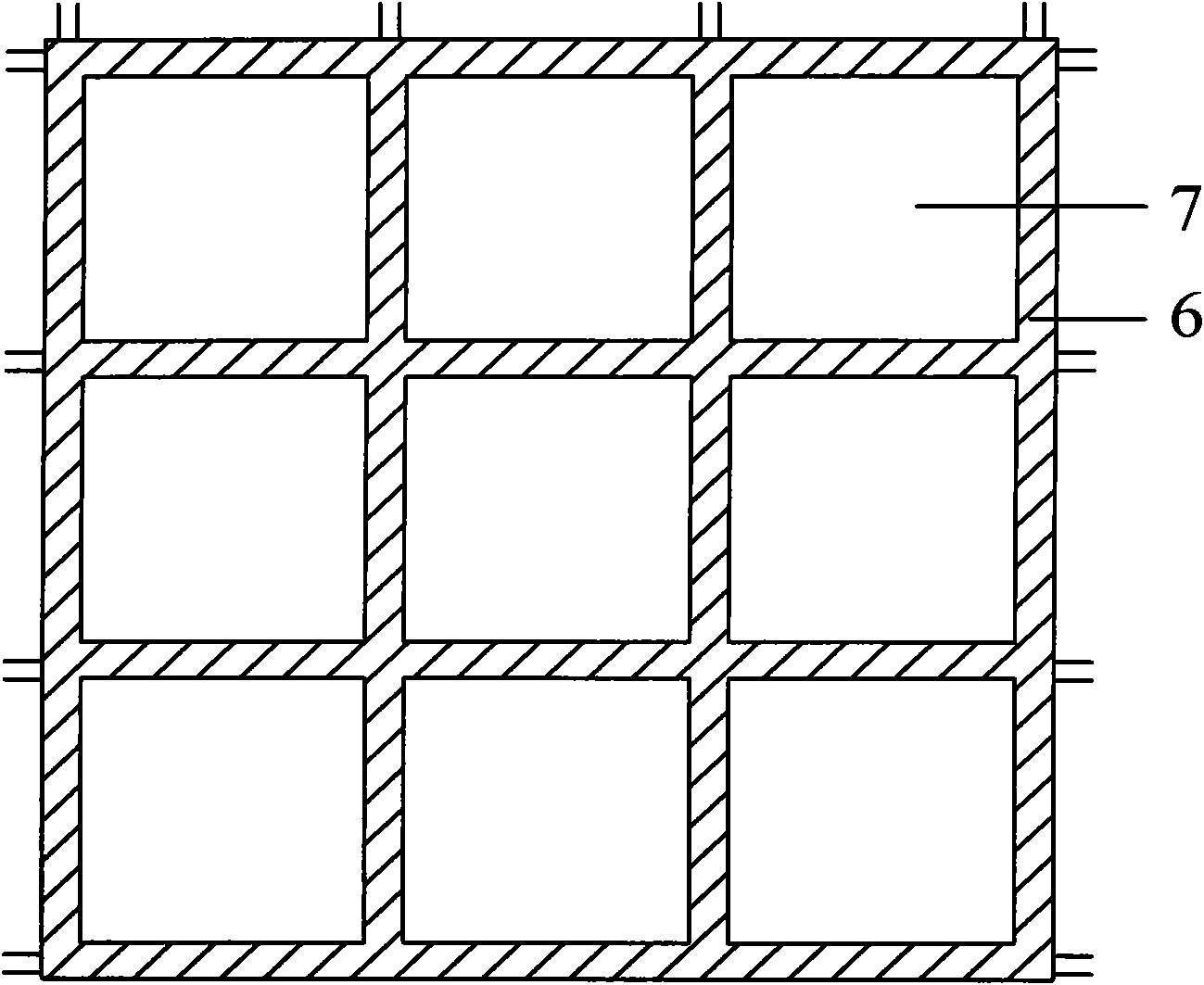

[0030] figure 1 and figure 2 It is a schematic diagram of the overall structure and cross-section of a kind of integration technology of external thermal insulation of dense-ribbed composite exterior wall panels according to the present invention. The ribbed composite exterior wallboard consists of a densely ribbed composite wallboard 1, an insulating layer 2 arranged on the outer surface of the densely ribbed composite wallboard 1, and steel wires arranged outside the insulating layer 2 for plastering the outer layer and preventing cracks Mesh 3 and outer layer plastering 5 are formed; among them, connect rib type composite wallboard 1, insulation layer 2 and steel wire mesh 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com