Chemical oxygen demand soft-sensing method of sewage

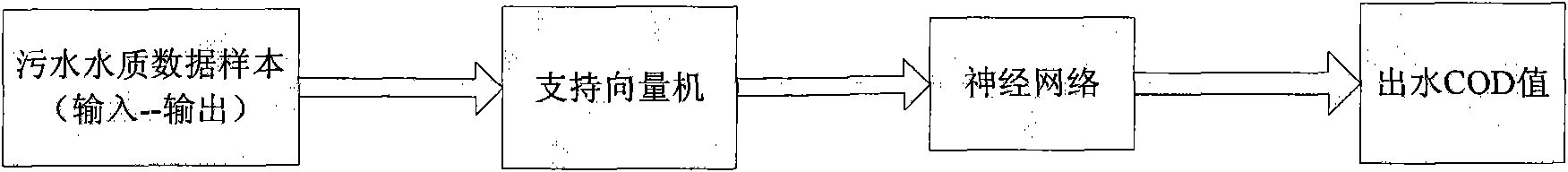

A chemical oxygen demand and soft measurement technology, applied in the field of sewage treatment, can solve the problems of cumbersome operation, demanding application conditions, large consumption of silver salt, etc., and achieve the effect of high estimation accuracy and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

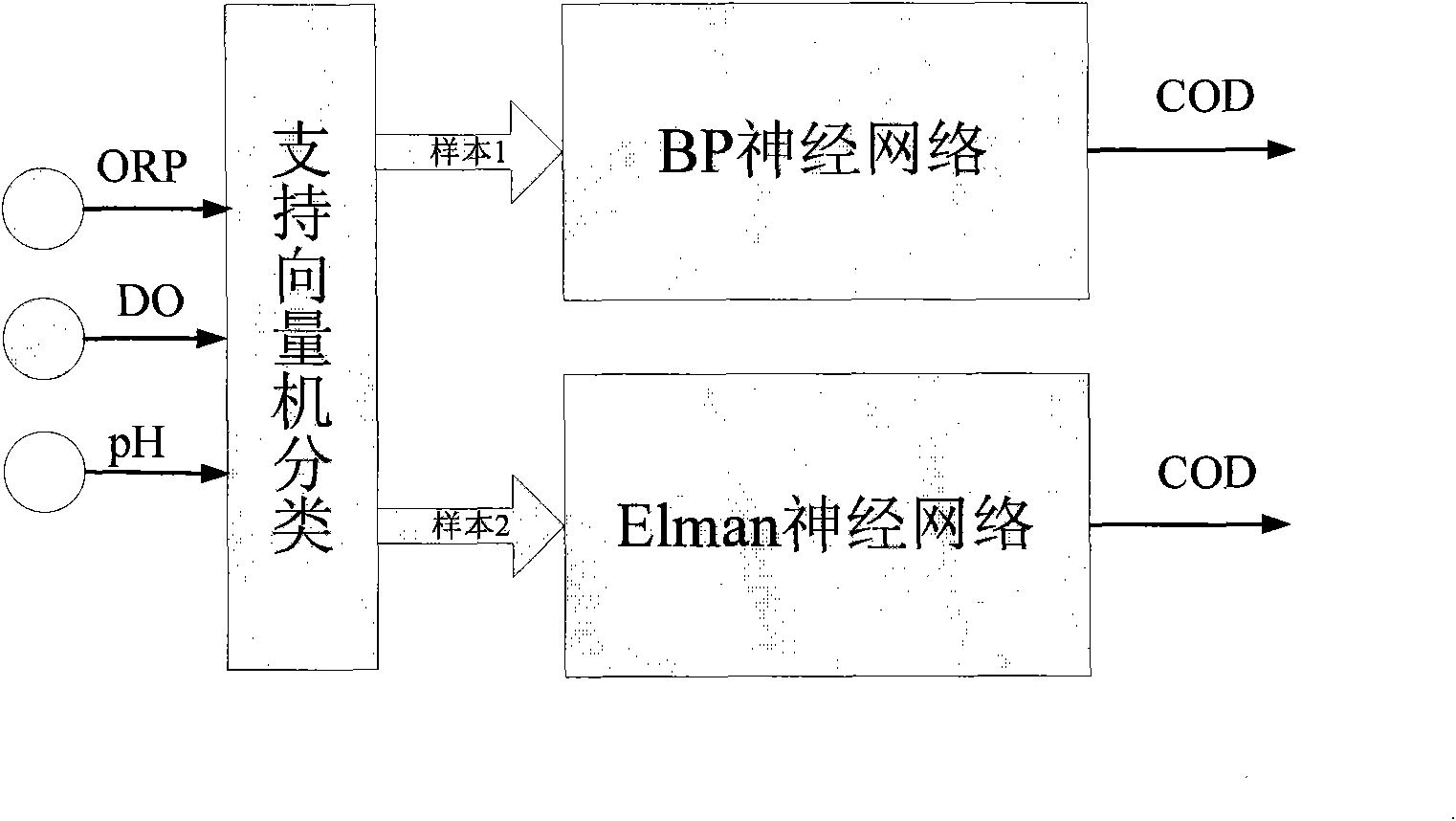

[0050] Example 1 uses the mean value of the COD of the training samples as the basis for classification, and the classification limit is 58 mg / L. Sample 1 is a training data sample with a COD value greater than 58 mg / L, and sample 2 is a training data sample with a COD value less than or equal to 58 mg / L.

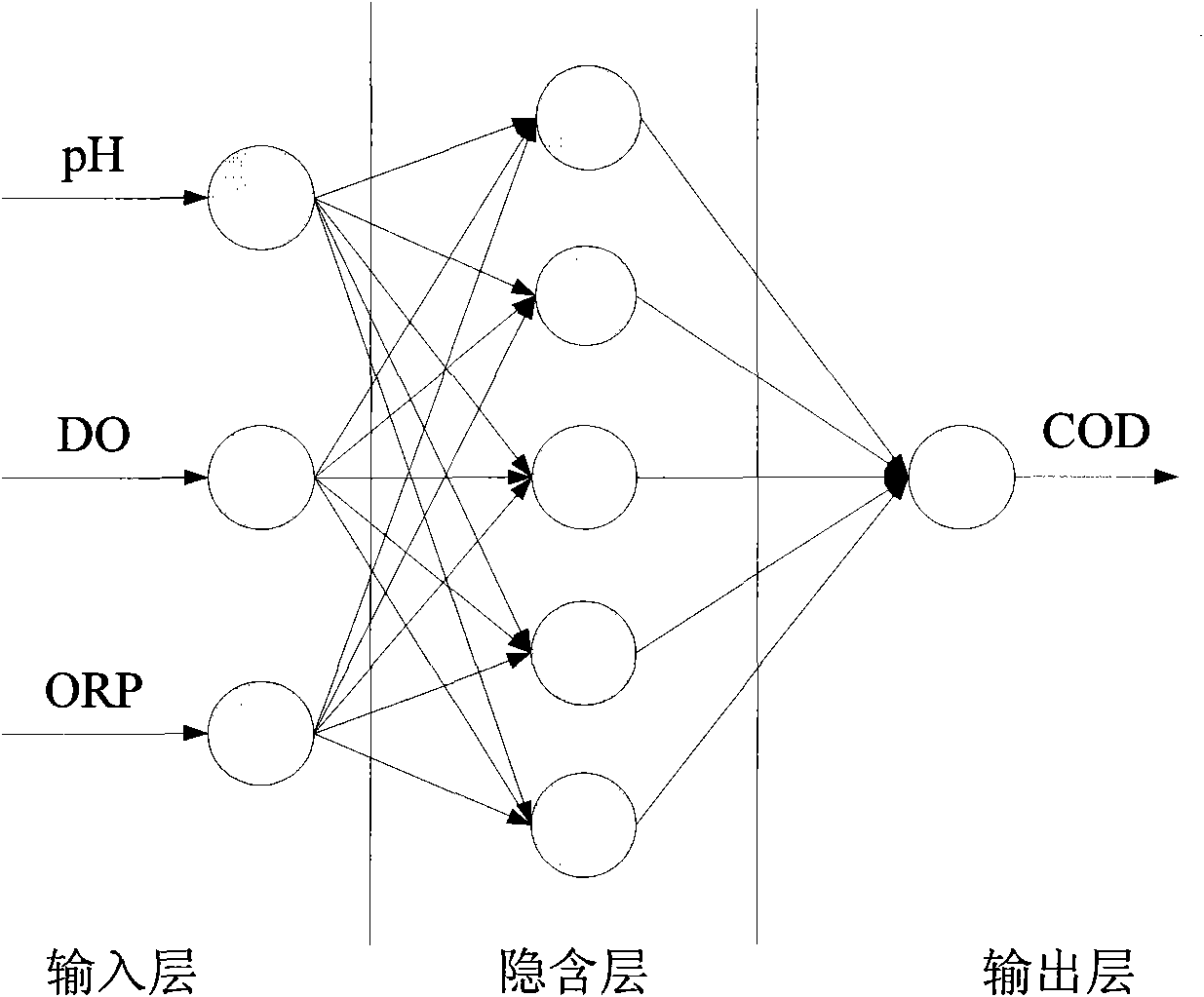

[0051] In sample 1, the COD value is large, the decline speed is fast, and the correlation in time is not high, so sample 1 selects BP neural network for training. Use pH, DO and ORP measured online as input layer nodes, COD as output layer nodes, and select five hidden layer nodes to establish a BP network model (such as image 3 ).

[0052] In sample 2, the COD value is small, the reaction time of the processing process is long, and the time correlation is high, so the Elman neural network is selected for training in sample 2. Similarly, with online obtained pH, DO, ORP as the input layer node, COD as the output layer node, select eight hidden layer nodes and eight rece...

Embodiment 2

[0054] Example 2 uses the anaerobic and aerobic states as the basis for classification. In this embodiment, the anaerobic and aerobic states of sewage are judged by the value of dissolved oxygen (DO), and the classification limit is DO=0.7mg / L. Sample 1 is a training data sample with a DO value less than 0.7 mg / L, and sample 2 is a skilled data sample with a DO value greater than 0.7 mg / L.

[0055] Sample 1 selects BP neural network to train, is the same as embodiment 1, uses online measured pH, DO, ORP as input layer node, COD as output layer node, and selects five hidden layer nodes to set up BP network model (such as image 3 ).

[0056] Sample 2 selects the Elman neural network for training. Similarly, the pH, DO, and ORP obtained online are used as input layer nodes, and COD is used as the output layer node. Eight hidden layer nodes and eight successor layer nodes are selected to establish an Elman network model (such as Figure 4 ).

[0057] First use all the training ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com