Microwave and heating element combined heating type heating chamber and manufacturing method thereof

A heating type, heating chamber technology, applied in the direction of microwave heating, etc., can solve the problems of poor heating uniformity, low thermal efficiency, difficult to replace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The first embodiment of the present invention will be described in detail below in conjunction with accompanying drawing 9 .

[0055] Fig. 9 is a schematic diagram of the "microwave and exothermic element mixed heating heating chamber" and its components according to the first embodiment of the present invention. The heating chamber in this embodiment is composed of a wave-absorbing heating element 3, an integrated heating element carrier plate, a thermal insulation layer 5, and a heating cavity upper cover 8, wherein "integrated heating element carrier plate and heat insulating layer" A total of five boards (four around and one under the base) are assembled into a cube-shaped cavity with an open top. The cavity is used as a whole and then cooperates with the heating cavity upper cover 8 to form a complete heating cavity. Methods as below:

[0056] (1) Make "integrated heating sub-carrier and heat insulation layer 5" and heating chamber upper cover 8: as shown in Figur...

Embodiment 2

[0062] The second embodiment of the present invention will be described in detail below in conjunction with accompanying drawing 10 .

[0063] Fig. 10 is a schematic diagram of the "microwave and exothermic element mixed heating heating chamber" and its components according to the second embodiment of the present invention. The heating chamber in this embodiment is composed of a wave-absorbing heating element 3, an "integrated heating element carrier and heat insulation layer 5" (cavity body) and a heating chamber base 9, wherein the integrated heating element carrier and insulation The thermal insulation layer forms a cylindrical cavity with an opening at the bottom, and the cavity as a whole cooperates with the heating cavity base 9 to form a complete heating cavity. The manufacturing method is as follows:

[0064] (1) Making microwave absorbing heating element: order a small cylindrical SiC absorbing heating element 3 of the required size from a specialized manufacturer, or...

Embodiment 3

[0069] The third embodiment of the present invention will be described in detail below in conjunction with accompanying drawing 11 .

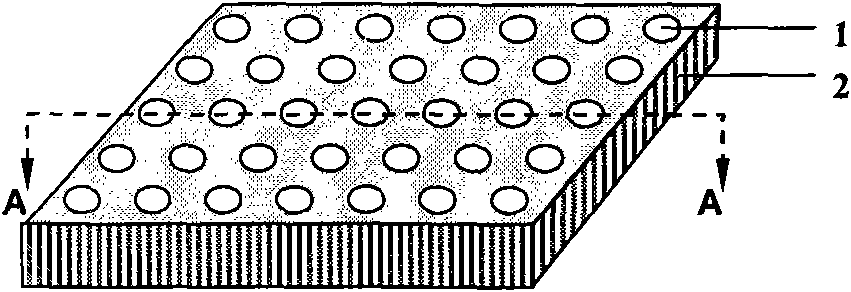

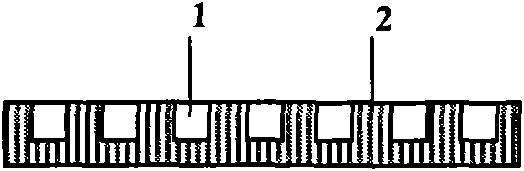

[0070] Fig. 11 is a schematic diagram of the "Microwave and Heating Element Mixed Heating Heating Chamber" and its components according to the third embodiment of the present invention. The heating cavity in this embodiment is composed of a wave-absorbing heating element 3, a heating element carrier 2, a heat insulation layer 10, and a heating cavity upper cover 8', wherein the heating element carrier 2 and the heat insulation layer 10 are respectively an upper The cuboid-shaped cavity with an opening, they work together as a whole and cooperate with the upper cover 8' of the heating cavity to form a complete heating cavity. The manufacturing method is as follows:

[0071] (1) Making microwave absorbing heating element: order a small cylindrical SiC absorbing heating element 3 of the required size from a specialized manufacturer, or directly pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com