Microwave heater for heating liquid and/or gases

A microwave heater and gas heating technology, which is applied in microwave heating, fluid heater, lighting and heating equipment, etc., can solve the problems of electric heating tube rupture, hidden danger of electric leakage, and difficulty in precise control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

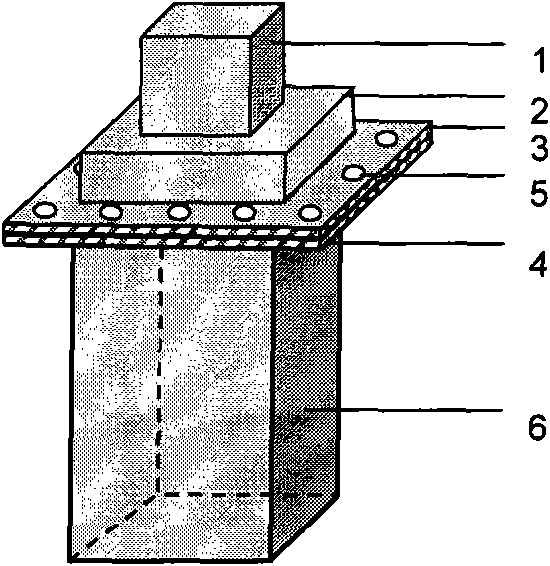

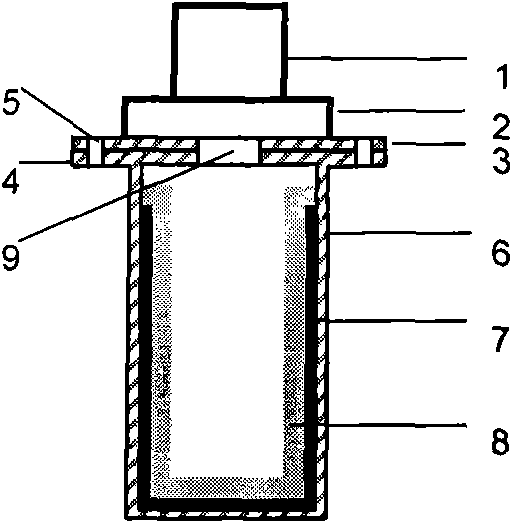

[0039] Attached below Figure 4 The first embodiment of the present invention will be described in detail.

[0040] Figure 4 A first embodiment of a microwave heater for liquid and / or gas heating according to the invention is shown. The microwave heater unit in this embodiment is composed of a heating cavity, a microwave generator, and a temperature measurement and control system. The heating cavity is composed of three functional layers: the outer anti-wave heat transfer metal shell 6, and the middle wave-absorbing heating layer 7 And the inner wave-transparent heat insulation layer 8, the microwave generator includes a magnetron 1, a waveguide 2, a transformer and a safety control device ( Figure 4 Not shown in ), safety control devices include high voltage insurance, capacitors, diodes and mica, temperature measurement and control system ( Figure 4 not shown in ) including thermocouples, thermostats and contactors. Among them, a mica sheet is fixedly placed between t...

Embodiment 2

[0045] Attached below Figure 5 The second embodiment of the present invention will be described in detail.

[0046] Figure 5 A second embodiment of a microwave heater for liquid and / or gas heating according to the invention is shown. The microwave heater in this embodiment is made up of 2 microwave heater units in embodiment 1 connected in series, and the structure and working principle of each microwave heater unit are the same as described in embodiment 1, but 2 microwave heaters The unit is equipped with a temperature measurement and control system, wherein the thermocouple temperature measuring end is placed near the outlet of the flowing liquid and / or gas 11 to detect the temperature, so as to realize the temperature control of the flowing liquid and / or gas 11 .

[0047] The working principle of the microwave heater described in Embodiment 2 is actually to use multiple microwave heater units in series, so that it can be used for rapid heating of large-scale flowing li...

Embodiment 3

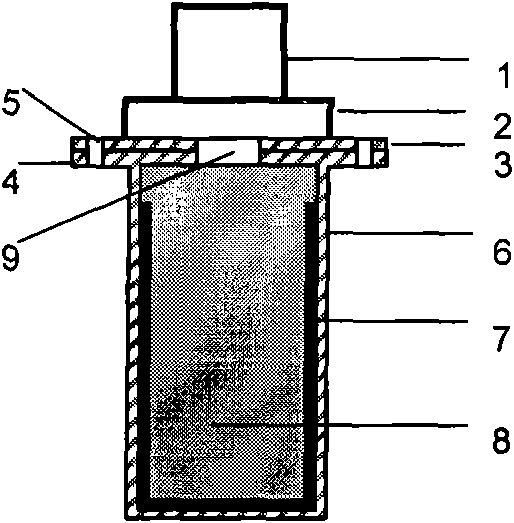

[0049] Attached below Figure 6 The first embodiment of the present invention will be described in detail.

[0050] Figure 6 A third embodiment of a microwave heater for liquid and / or gas heating according to the present invention is shown. The microwave heater unit in this embodiment is composed of a heating cavity, a microwave generator, and a temperature measurement and control system. The heating cavity is composed of three functional layers: the outer anti-wave heat transfer metal shell 6, and the middle wave-absorbing heating layer 7 And the wave-transparent heat-insulation layer 8 near the lower cover 4 of the heating chamber, the microwave generator includes a magnetron 1, a waveguide 2, a transformer and a safety control device ( Figure 6 Not shown in ), safety control devices include high voltage insurance, capacitors, diodes and mica, temperature measurement and control system ( Figure 6 not shown in ) including thermocouples, thermostats and contactors. Amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com