Detachable hollow-fibre membrane component

A fiber membrane and hollow technology, applied in the field of water treatment, can solve the problems of decreased membrane water production, inconvenient cleaning and restoration, and high maintenance costs, and achieve the effects of reduced sludge deposition, convenient cleaning and restoration, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

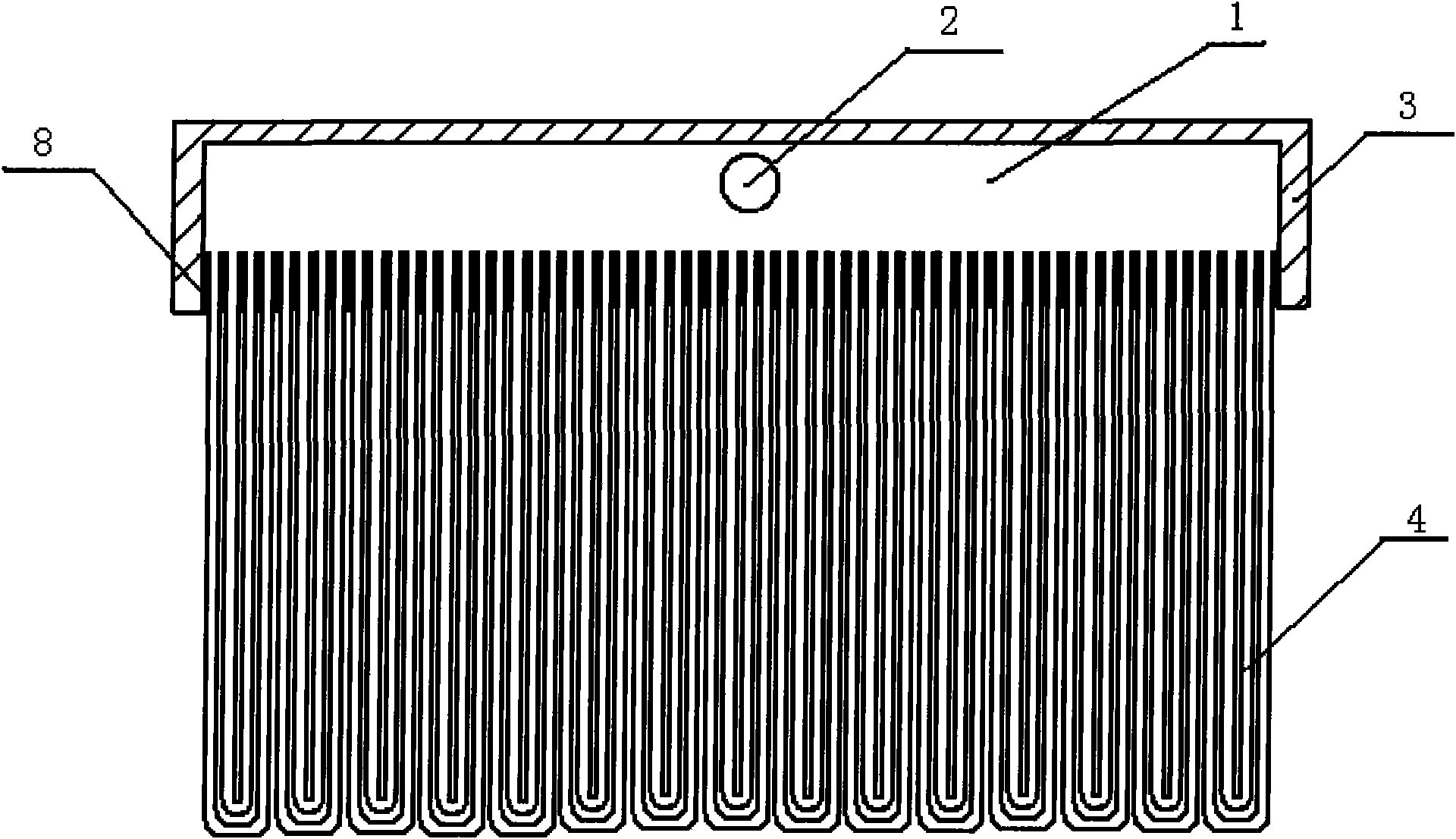

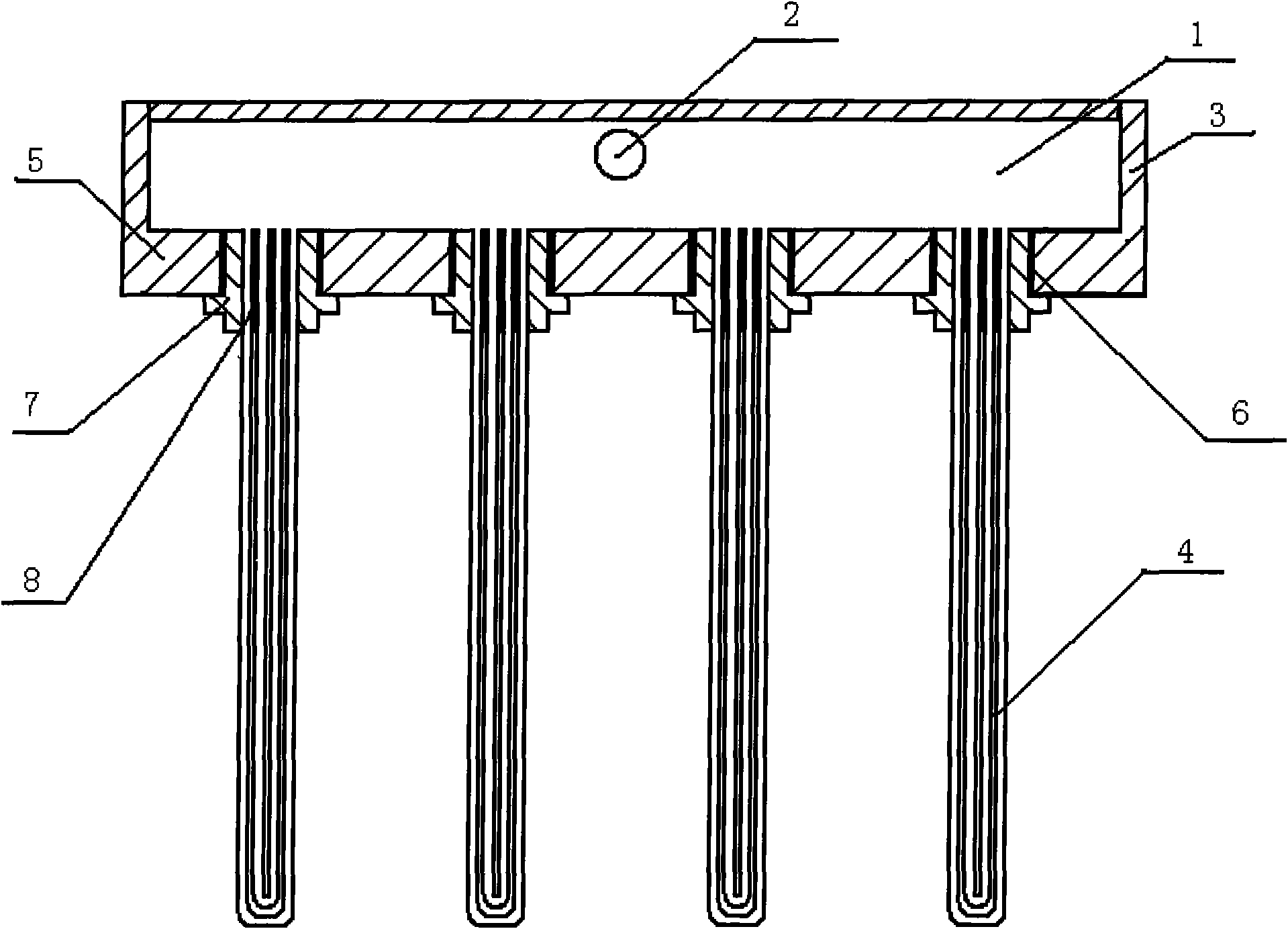

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] A detachable and washable hollow fiber membrane module, including a water collection tank 1, an outlet pipe 2, a connecting piece 3 and a hollow fiber membrane 4, one end of the connecting piece is provided with a connecting plate 5, and the connecting plate is provided with 2 to 1000 connecting holes 6, each A connecting hole is flexibly connected with the connecting pipe 7, and the end of the hollow fiber membrane is fixedly connected with the inner surface of the connecting pipe through an adhesive 8.

[0021] The shape of the connector is one of rectangle, circle or rounded rectangle.

[0022] The connection between the connection hole and the connecting pipe is an "O" ring connection, preferably an "O" ring connection with a card slot.

[0023] The connection between the connecting hole and the connecting pipe can also be a threaded connection with a gaske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com