Mirror surface rolling tool with internal cooling lubricating function

A tool and functional technology, which is applied in the field of cold machining, can solve the problem of increased oil or coolant usage, and achieve the effects of reduced usage, obvious effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

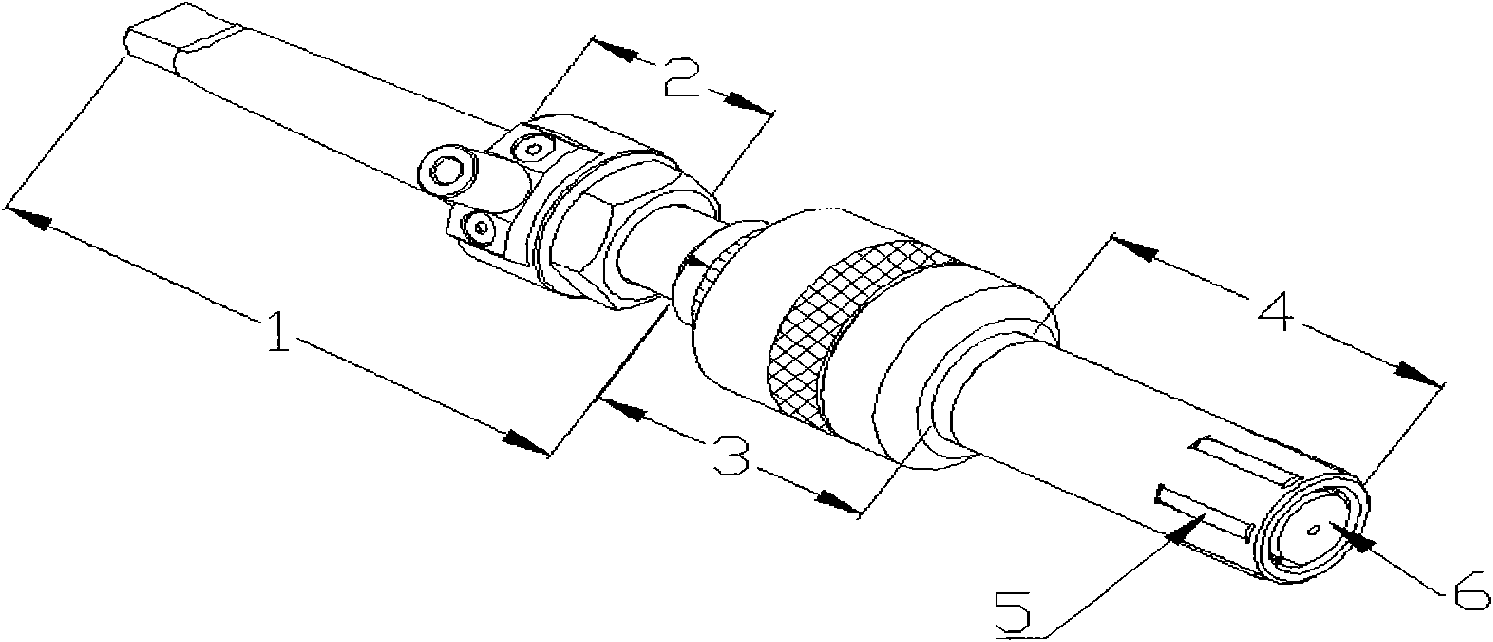

[0016] figure 1 Shown is an outline drawing of a mirror rolling tool with internal cooling and lubrication functions disclosed by the present invention.

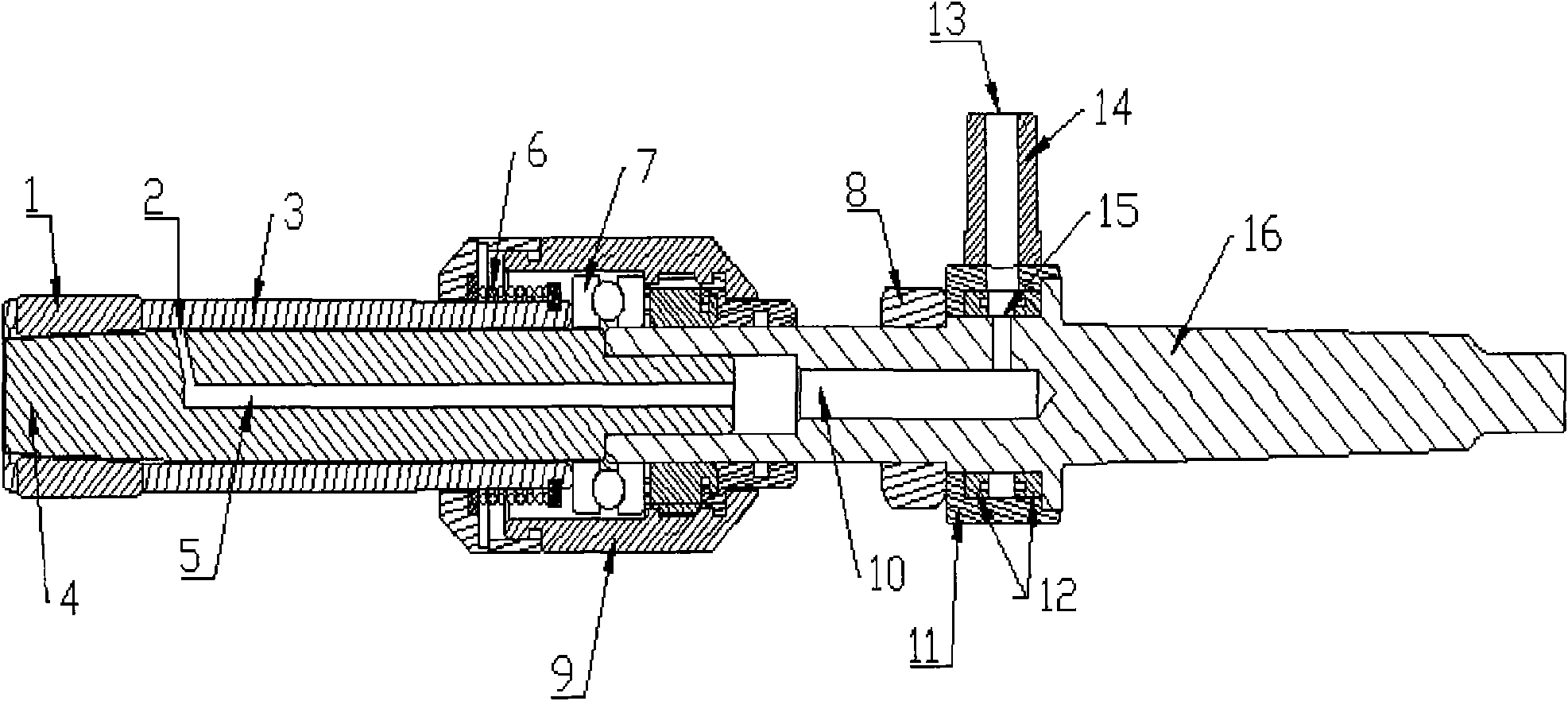

[0017] figure 2 It is a cross-sectional view of a rolling tool with internal cooling and lubricating mirror surface function.

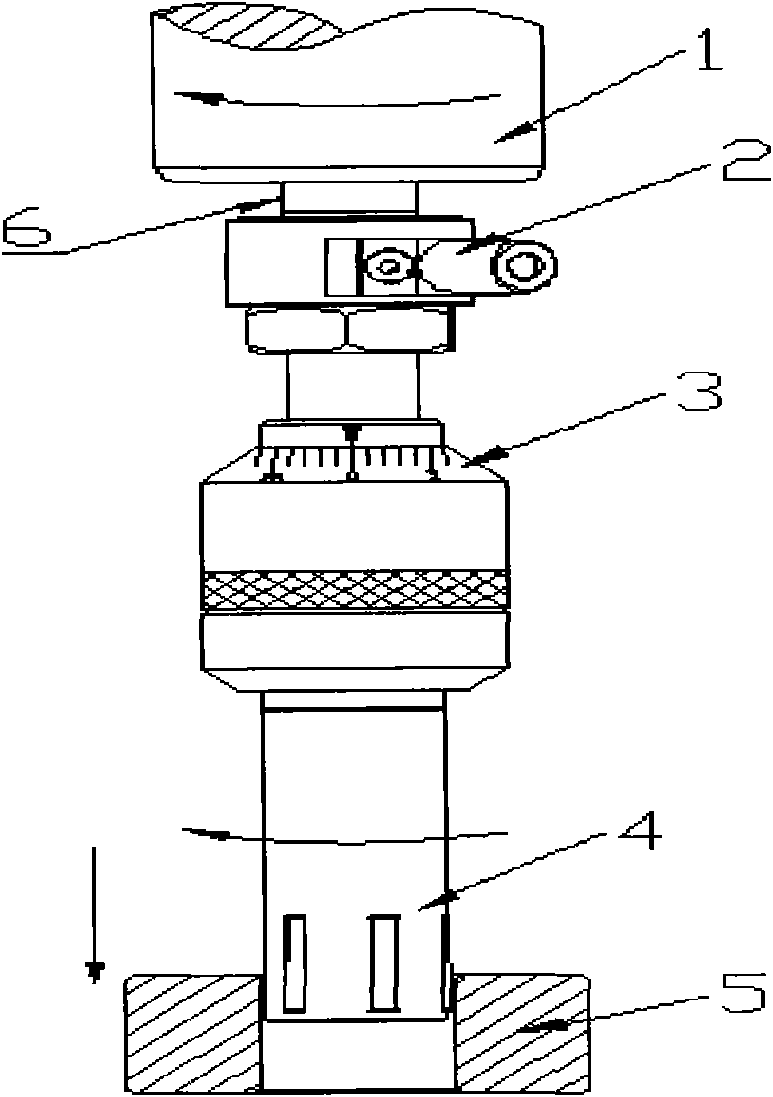

[0018] image 3 Shown is a schematic diagram of the workpiece processed by the mirror rolling tool with internal cooling and lubrication function. The horizontal arrow indicates the rotation direction of the mirror rolling tool with internal cooling and lubrication function and the spindle of the machine tool; the vertical arrow indicates the tool feed direction, and (5) is The workpiece to be processed is fixed.

[0019] Before processing, connect the external oil supply device with (2) oil inlet device, connect (6) shank with the machine tool spindle, and press the too...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap