Fire coal self-controlled boiler

A boiler and coal-fired technology, which is applied in the field of coal-fired self-controlled boilers, can solve the problems of high exhaust gas temperature and low boiler thermal efficiency, and achieve the effects of improving heat exchange efficiency, improving heat transfer coefficient, and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

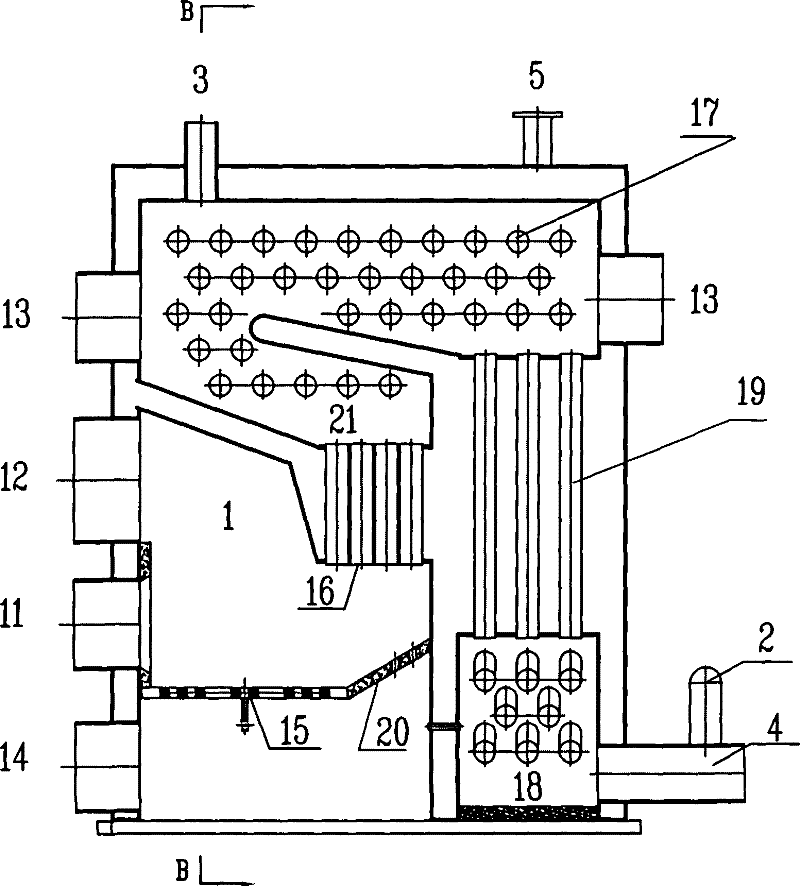

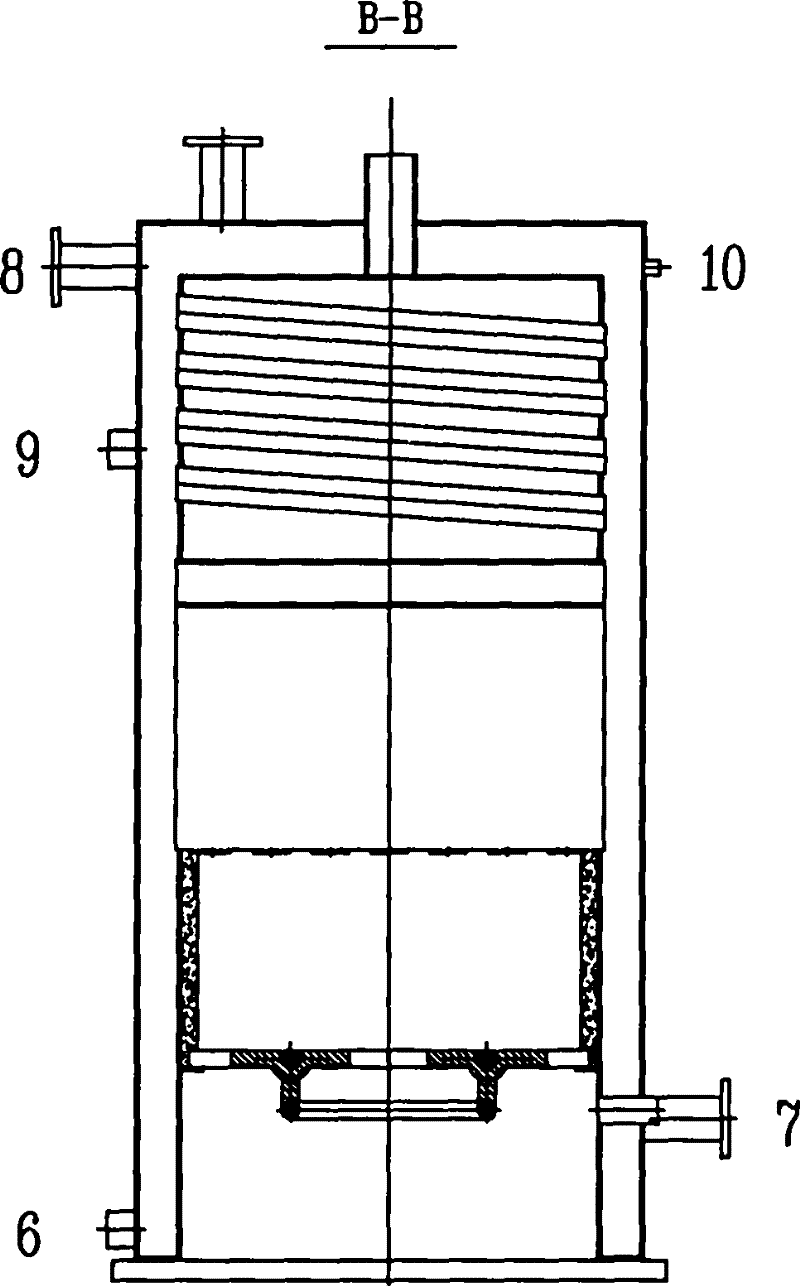

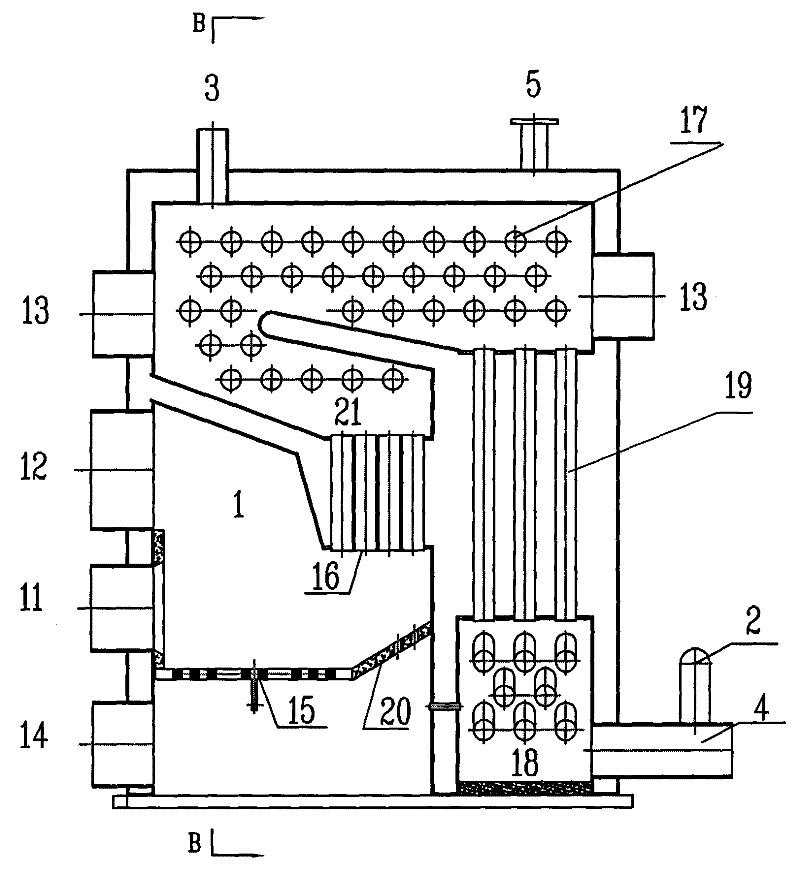

[0027] One of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a sectional side view of the coal-fired automatic control boiler of the present invention, figure 2 for figure 1 Sectional view of the B-B direction.

[0028] The outside of the coal-fired self-control boiler furnace body of the present invention is a vertical square structure, additionally with color packaging, the structure is compact, elegant in appearance, small in floor space, and easy to operate. Such as figure 1 As shown, the lower part of the furnace body is provided with a combustion chamber 1 facing the front, which is called the first return combustion chamber. The fire grate 15 provided in the first return combustion chamber 1 is a movable fire grate, and the fire grate is a movable fire grate that can be turned over at a certain angle. , Composed of two groups of grates, large boilers consist of four or more group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com