Balancing and positioning system for workpiece platform of photoetching machine

A technology of positioning system and lithography machine, which is applied in the field of semiconductor manufacturing, can solve the problems such as the difficulty of balancing the system control and increasing the complexity of the balancing and positioning system of the workpiece table, and achieve the effects of reducing the difficulty of vibration reduction, reducing the impact force and improving the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be further described in conjunction with the accompanying drawings.

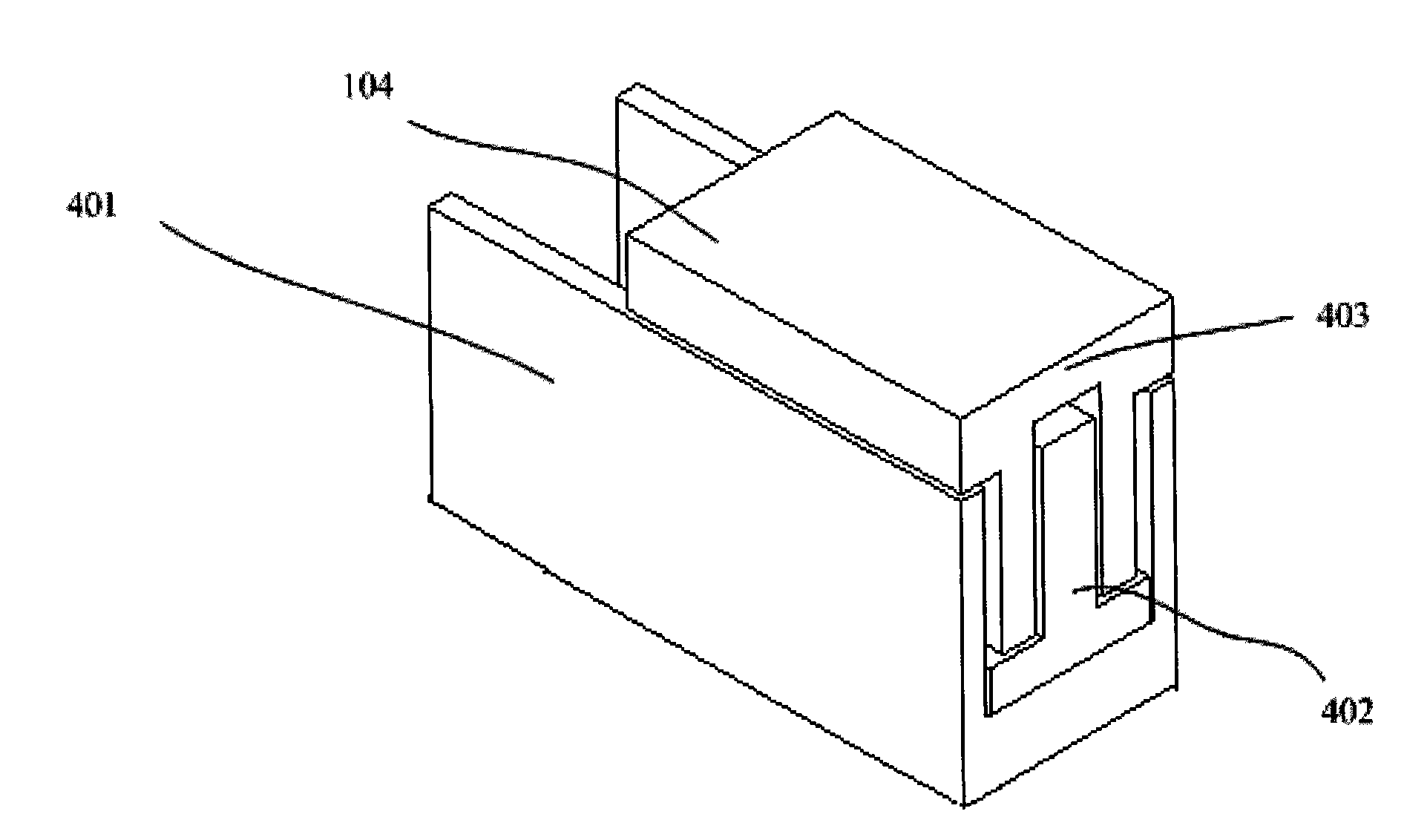

[0026] First, please refer to figure 1 , figure 1 It is a schematic structural view of the torque canceller of the present invention. As can be seen from the figure, the torque canceller 104 provided by the present invention includes a torque canceller base 401; a torque canceller motor rotor 402 is rigidly connected to the torque canceller base 401 The moment eliminator balance mass 403 is connected to the moment eliminator base 401 through a vertical air bearing and a lateral air bearing, wherein a magnet is housed in the moment eliminator balance mass 403. The technical effect of the canceller 104 is described in detail.

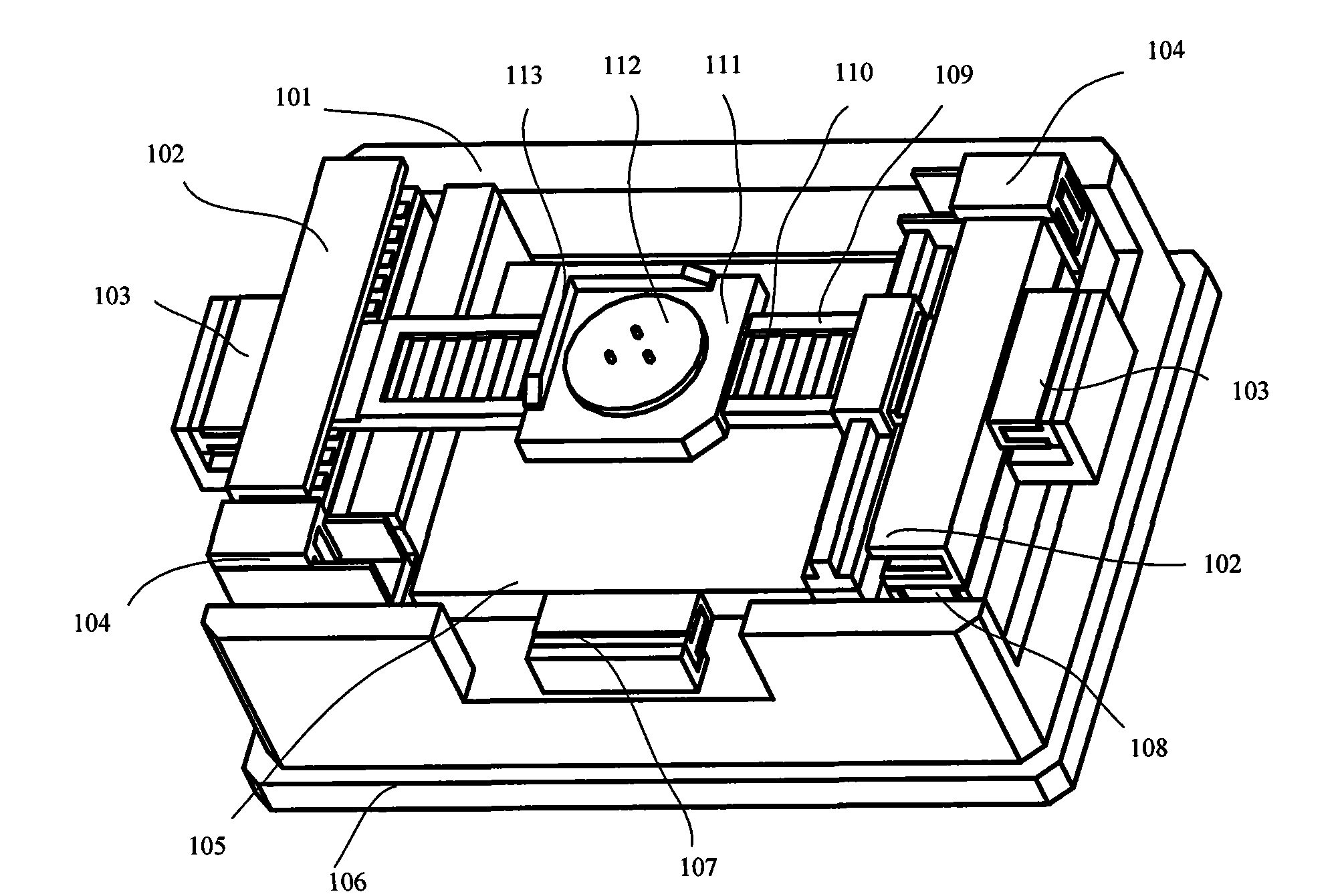

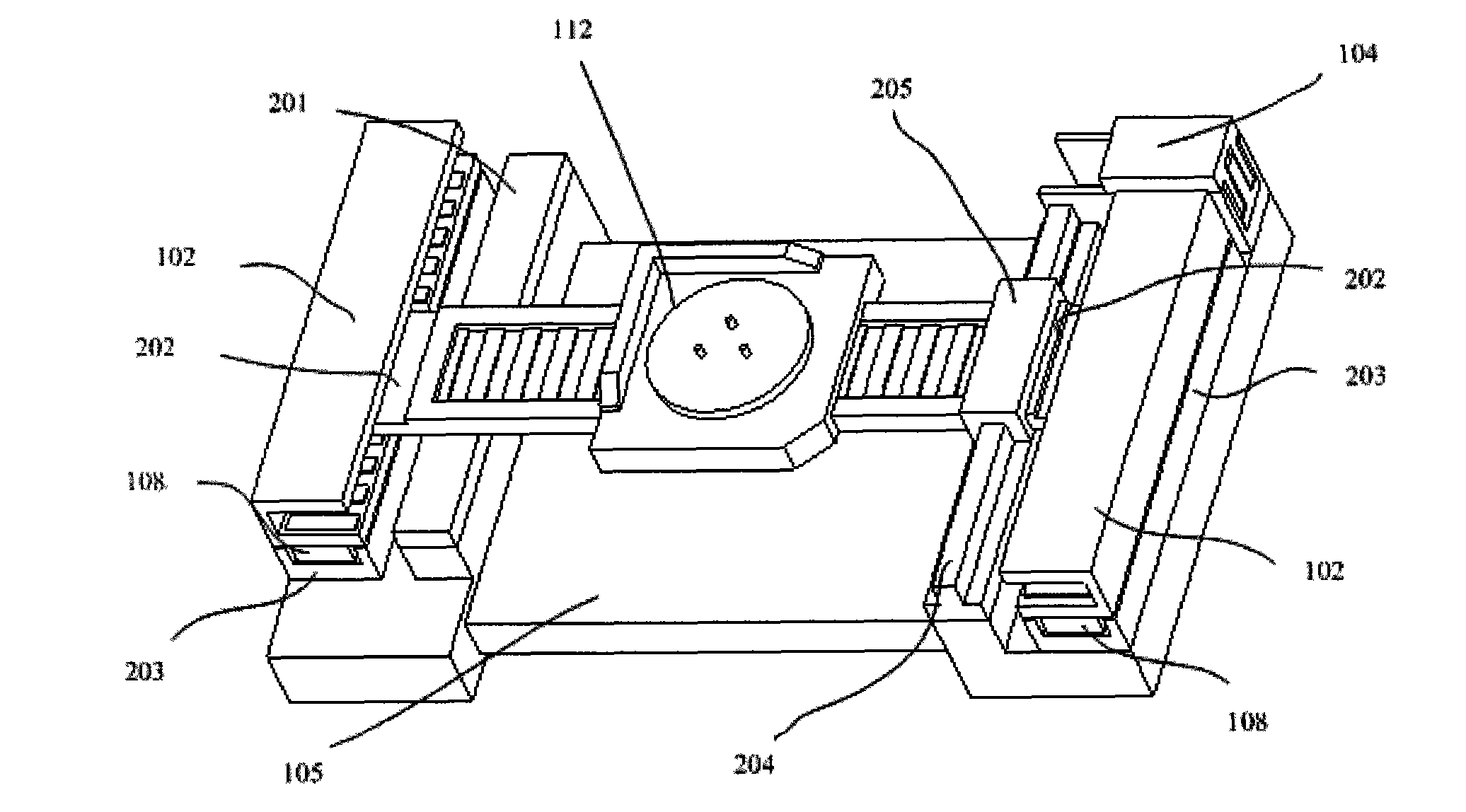

[0027] Then please refer to figure 2 , figure 2 It is a structural schematic diagram of the balanced positioning system of the lithography machine workpiece table of the present invention. In order to explain concisely and accurately, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com