Forced air cooling high thrust flat three-phase linear asynchronous motor

An asynchronous motor, high-thrust technology, used in electric components, electrical components, electromechanical devices, etc., can solve problems such as large size, and achieve the effects of small size, convenient disassembly, and reasonable air duct structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

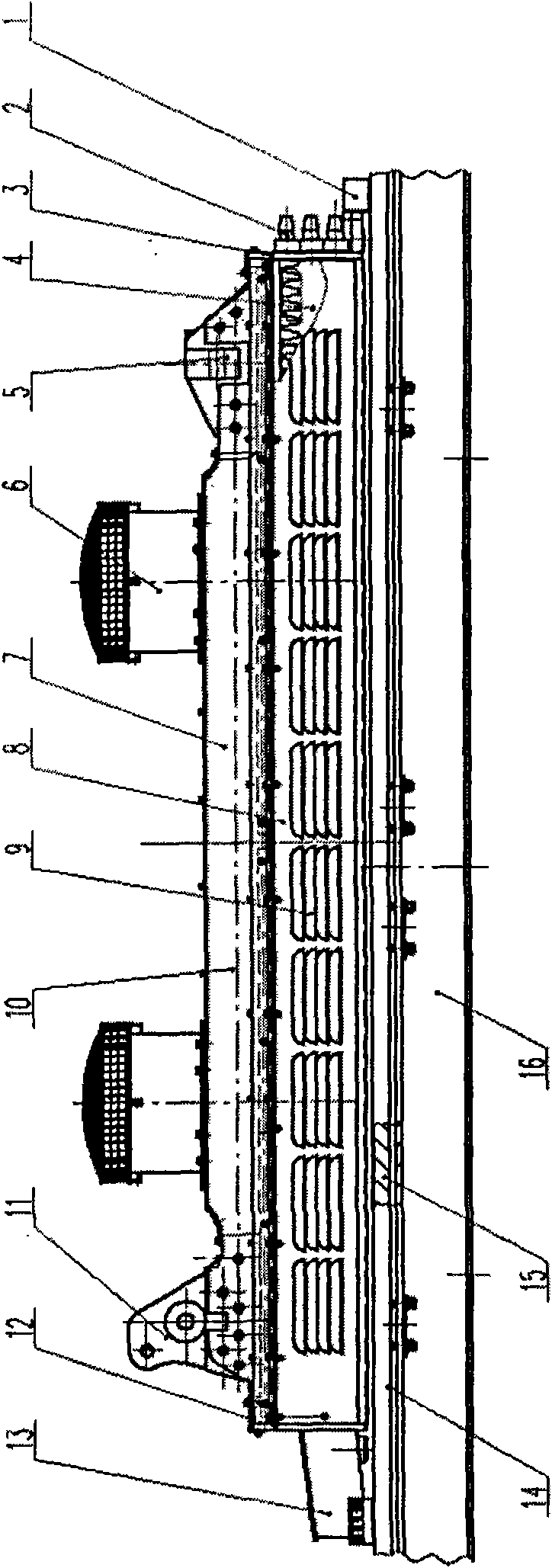

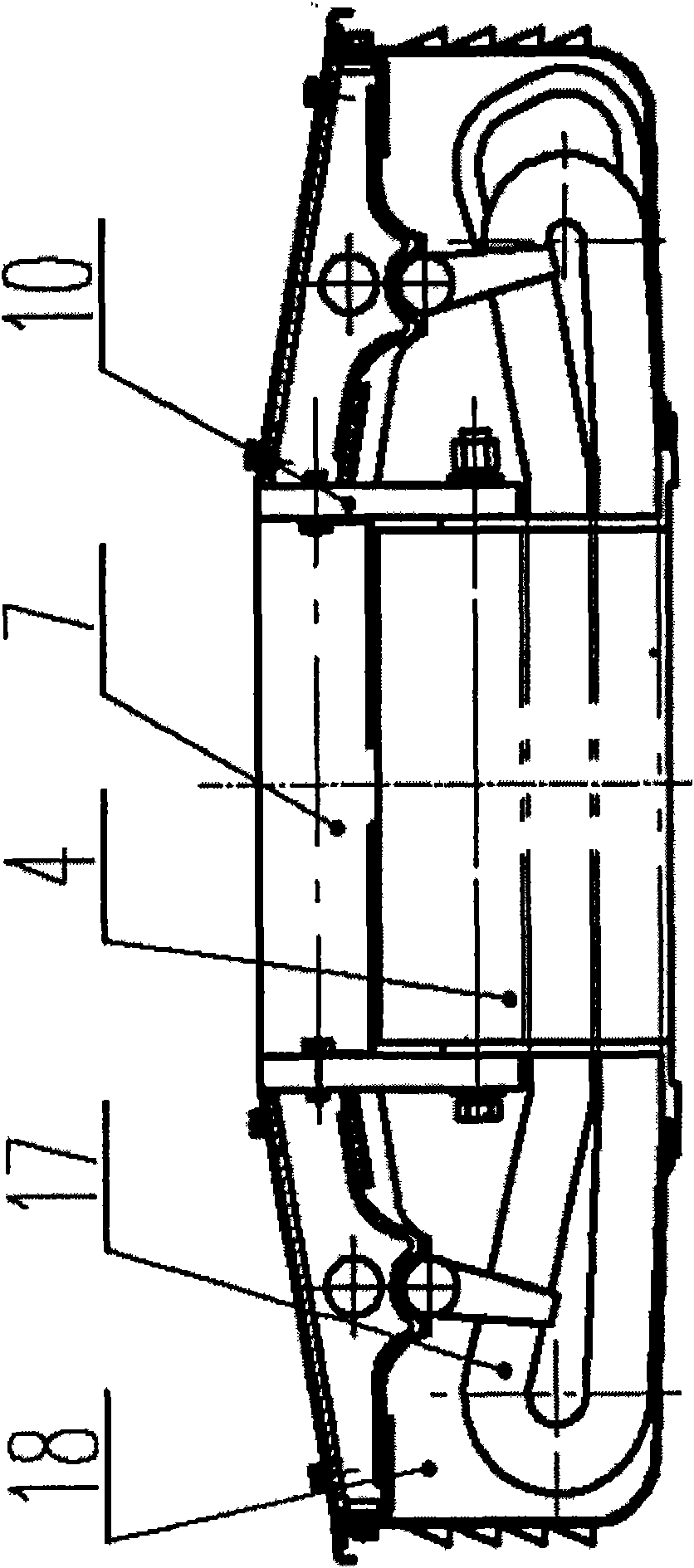

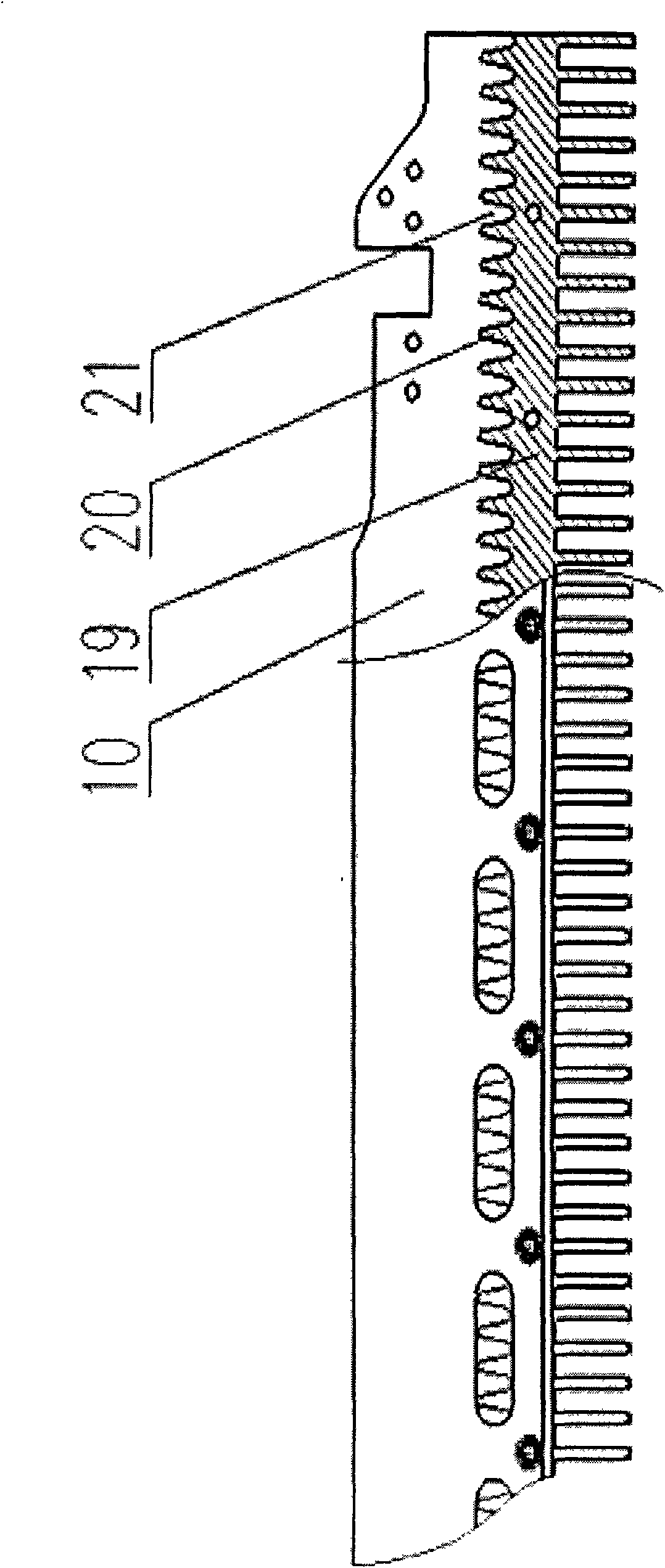

[0015] Such as figure 1 , figure 2 As shown, a forced-air-cooled high-thrust flat three-phase linear asynchronous motor consists of a primary and a secondary. The primary consists of a primary iron core 4 and a winding 17 located in the primary iron core 4. The cooling system consists of a fan 6 and an air-filled chamber. 7. The end air chamber 18 and the side windshield 8 are formed. At least one fan 6 is installed on the top of the air chamber 7. Both sides of the air chamber 7 are respectively connected to the end air chamber 18. The air chamber 7 communicates with the end air chamber 18 and An air flow channel is formed, and the channel reaches the end of the winding. Side windshields 8 are installed on both sides of the motor, the front barrier 13 is fixed on the front end plate 12, the rear barrier 1 is fixed on the rear end plate 3, and the winding 17 is connected by wiring Terminal 2 is connected to a dedicated variable frequency power supply, the secondary is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com