Method and device for realizing convex-concave composition plane non-circular grinding

A compound surface and grinding technology, which is applied in the direction of abrasive materials, abrasive belt grinders, metal processing equipment, etc., can solve the problems of low accuracy of profile turning, failure to meet production requirements, and roughness that cannot meet the requirements, and achieve the goal of solving difficult problems. Machinable and non-machinable, reliable performance, and the effect of improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments, but the protection scope of the present invention is not limited to the scope described in the embodiments.

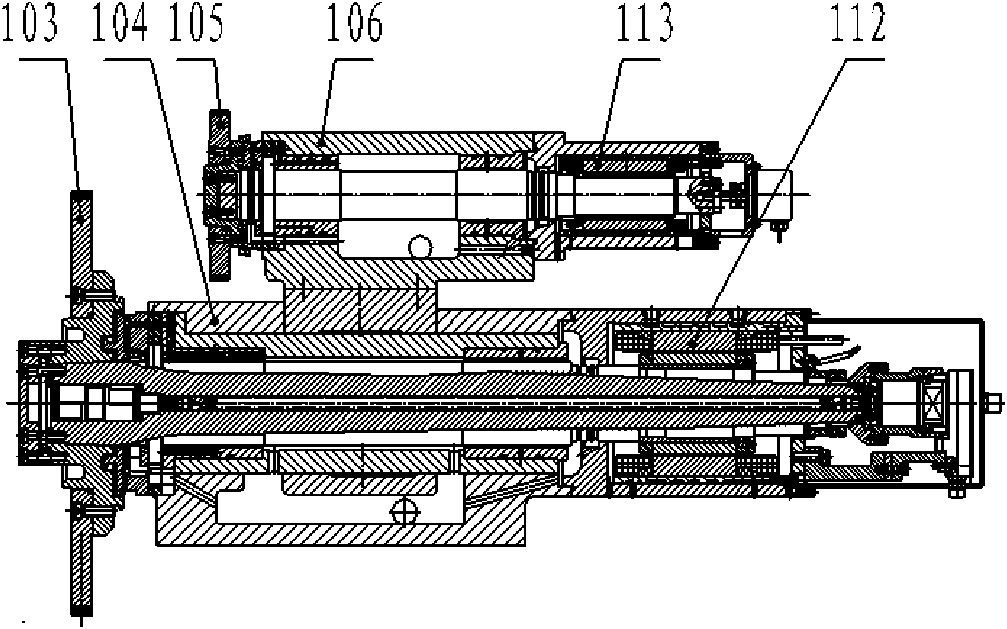

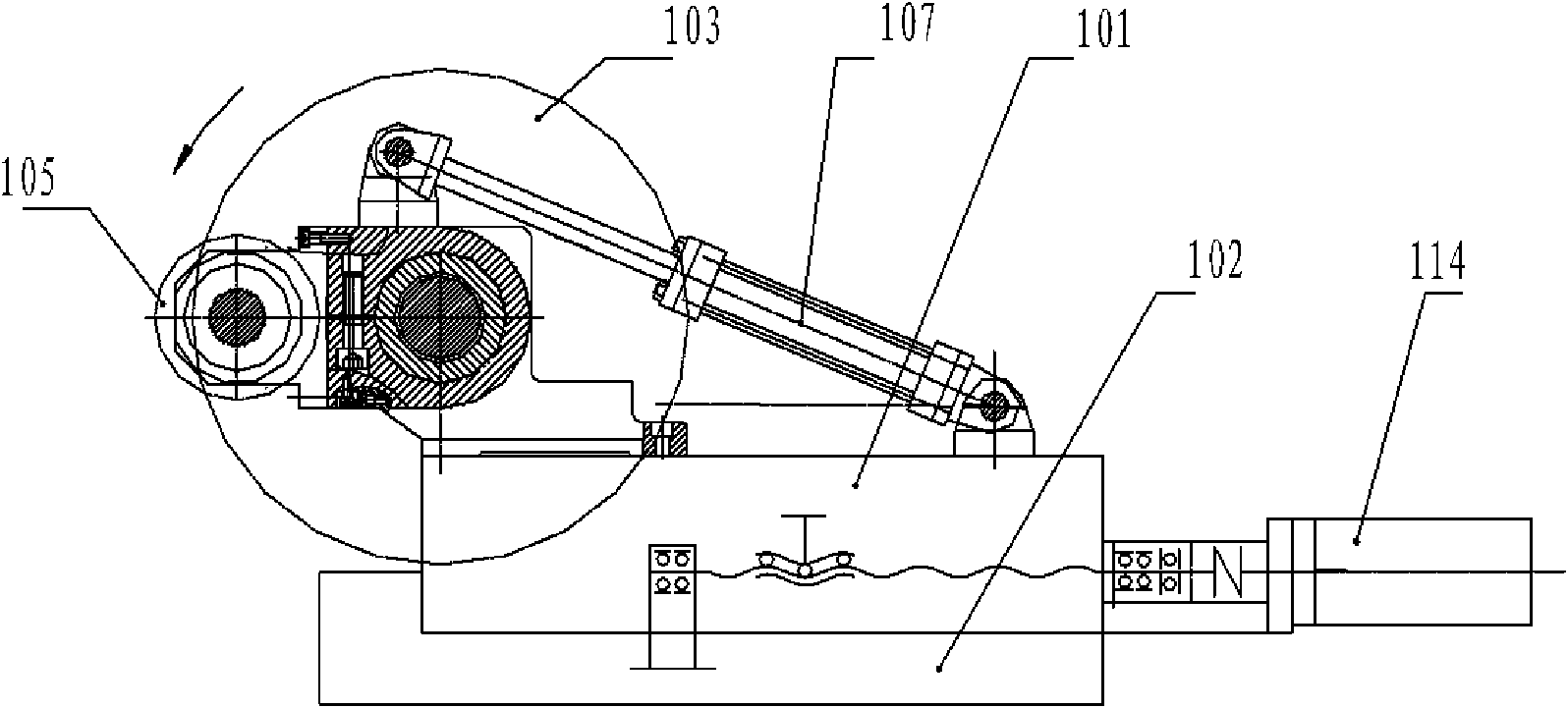

[0018] The non-circular grinding method of convex-concave compound surface provided by the present invention adopts the follow-up grinding method with large and small emery wheels, and the cam-shaped line is carried out rough grinding and semi-finish grinding with a large emery wheel, leaving a fine grinding allowance of 0.05 to 0.15 mm, and then Use a small grinding wheel for fine grinding and concave grinding to meet the technical requirements of the drawings.

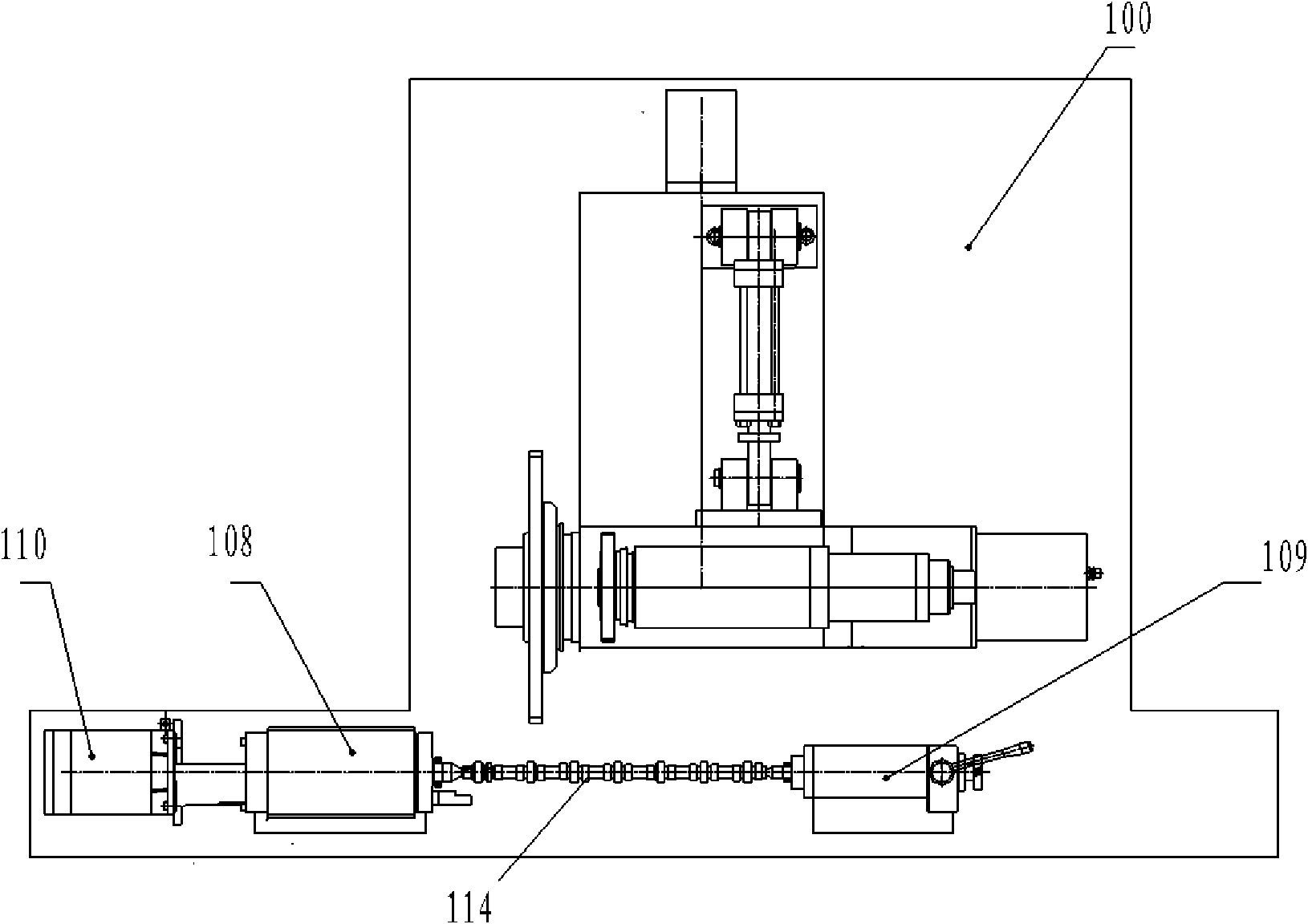

[0019] see figure 1 , figure 2 , image 3 and Figure 4 , the device provided by the present invention to realize the non-circular grinding method of convex-concave compound surface is equipped with a grinding wheel frame feeding system 102 on the bed 100, and a grinding wheel frame 101 and its f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com