Special hoisting tool with heat-preservation cover for hot metal charging in traveling crane

A technology of thermal insulation cover and spreader, applied in the field of special spreader, can solve the problems of increased heat loss, abnormal iron mixing operation, and increased difficulty in positioning the crown block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

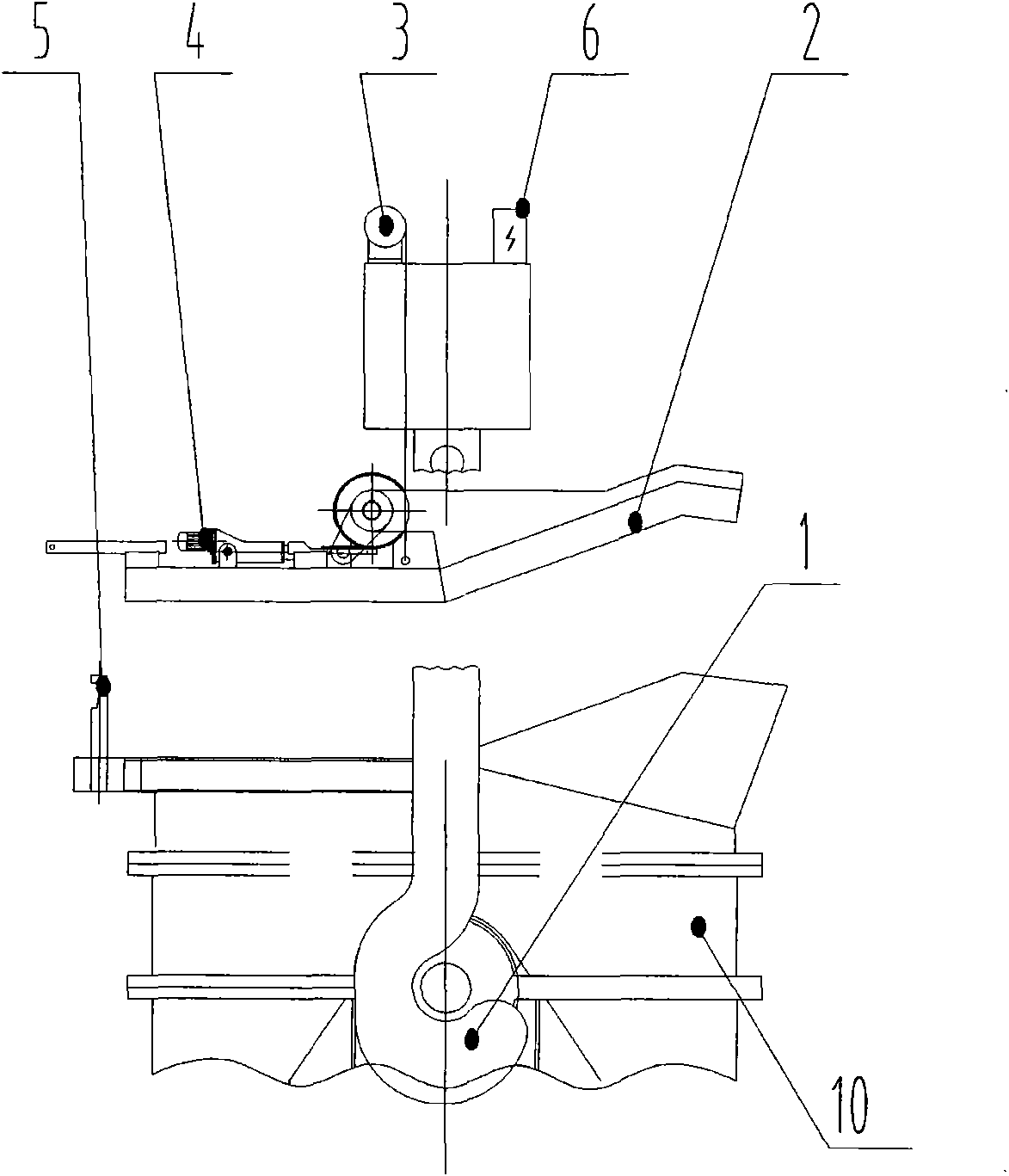

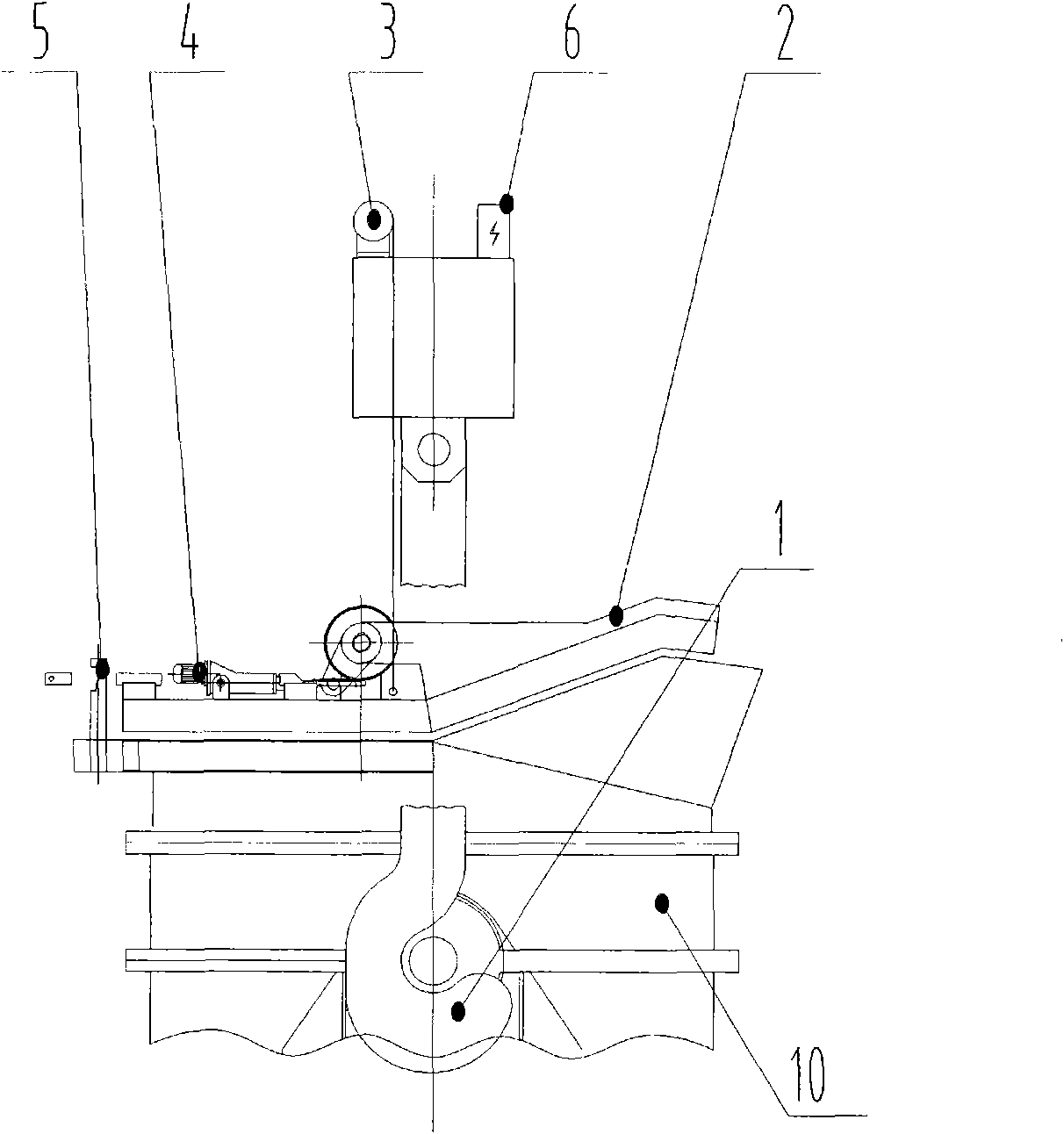

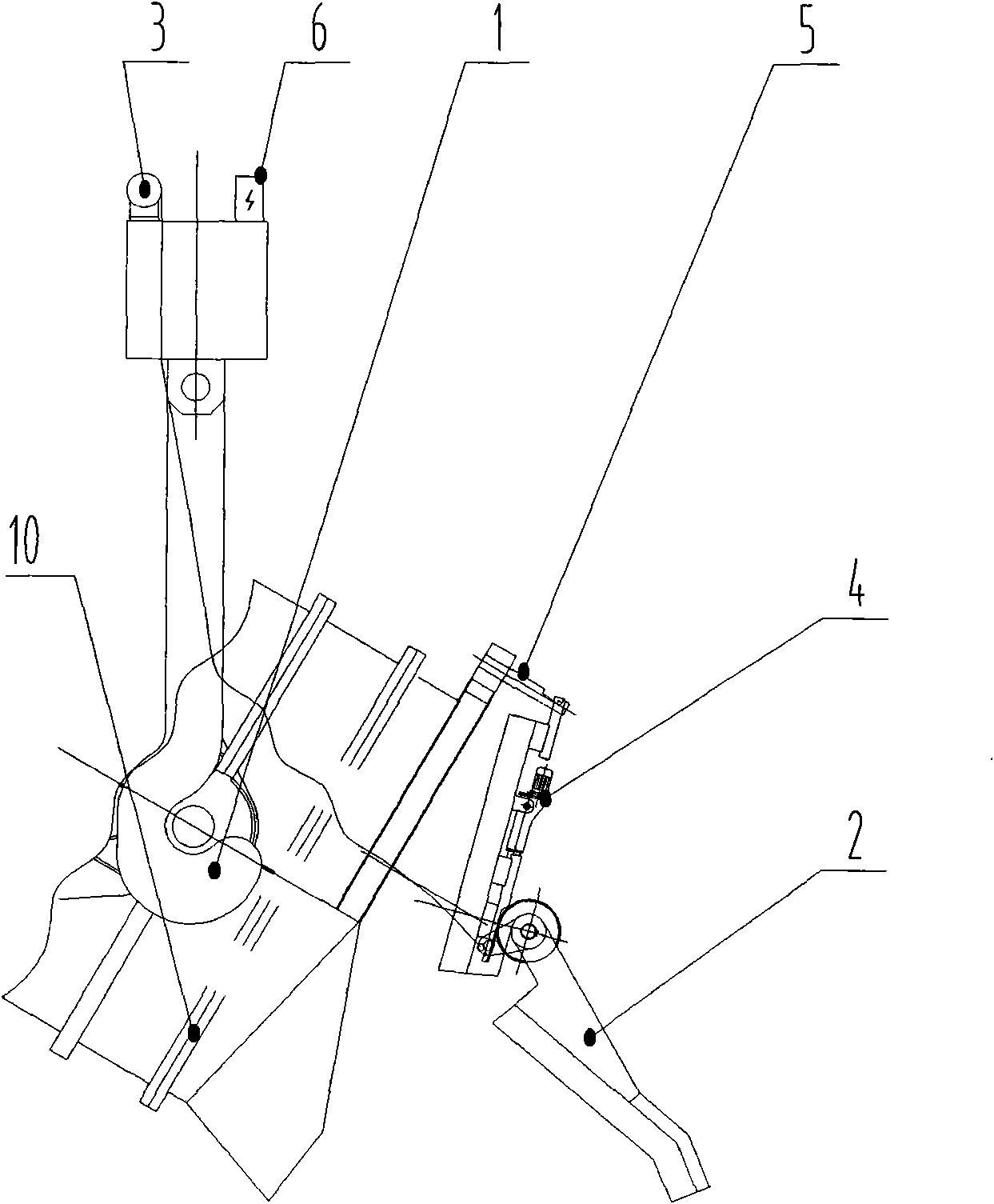

[0016] Figure 1~3 It is a specific embodiment of the present invention.

[0017] 1. Corresponding to the combined heat preservation cover in the form of front and back folding, the main hook of the crane and the ladle 10 are organically combined by means of the heat preservation cover lifting system 3 and the heat preservation cover folding and locking system 4 . Job description: For a full ladle, after the main hook completes the hooking, the special spreader is lowered from the standby position to the mouth of the ladle, and the anchor chain for suspension continues to descend to the maximum stroke; the heat preservation is completed before the ironing operation, that is, before the lifting of the small hook The hinge pin positioning of the cover and the opening operation of the side cover of the iron mixing nozzle; after the iron mixing operation is completed and the small driving hook is unhooked, the hinge pin of the heat preservation cover is disengaged and the locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com