Method of intensified denitrification and dephosphorization of urban sewage

A technology for nitrogen and phosphorus removal and urban sewage, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor nitrogen and phosphorus removal effect and high cost, and achieve Good effect, low cost, beneficial to growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

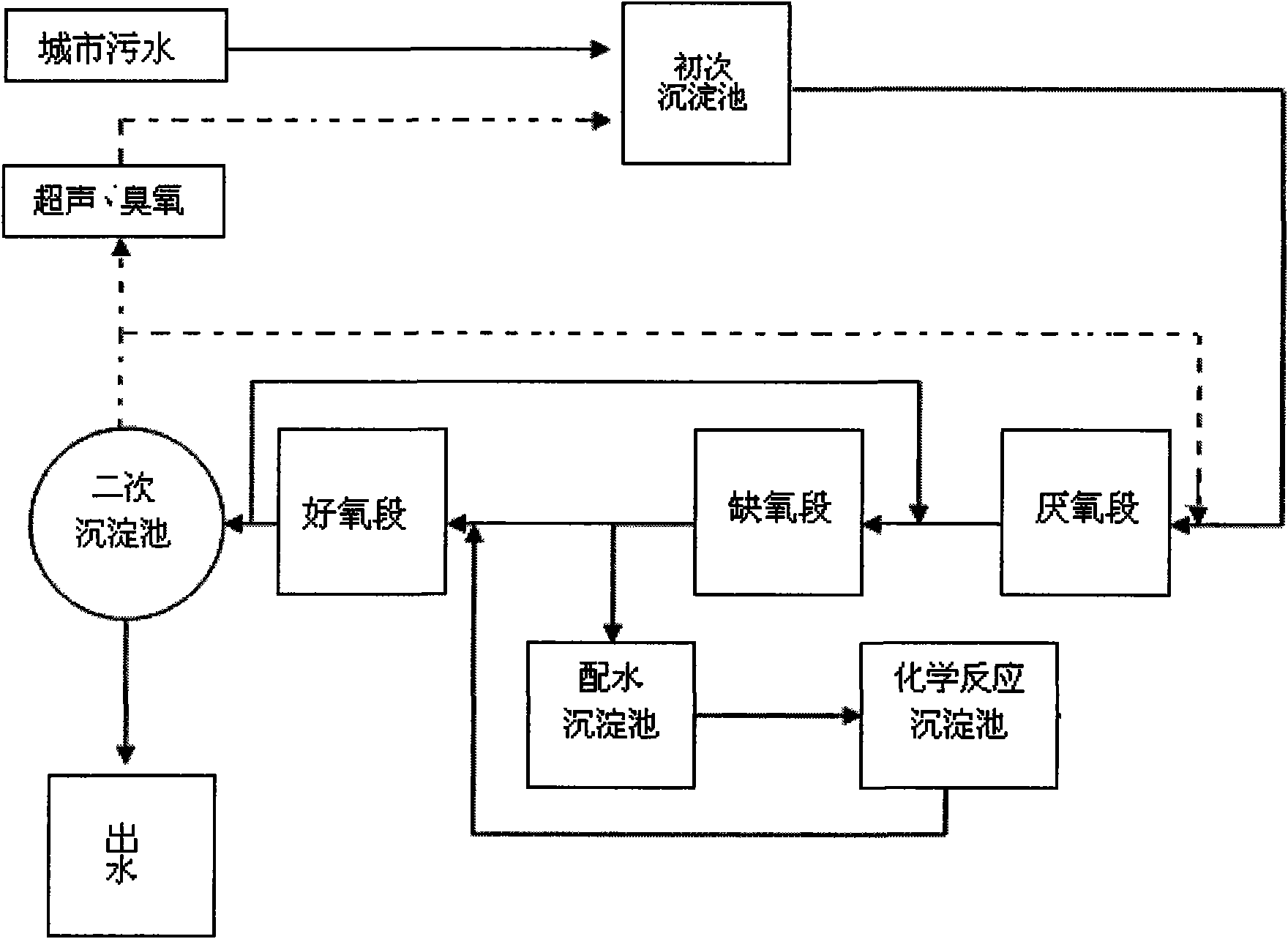

[0008] Specific embodiment one: the method for strengthening denitrification and dephosphorization of urban sewage in this embodiment is carried out according to the following steps: the method for strengthening denitrification and dephosphorization of urban sewage is carried out according to the following steps: a, account for 10% of the total volume of residual sludge in the secondary sedimentation tank %~40% of the sludge is ultrasonically crushed and ozone treated, and enters the primary sedimentation tank in an anaerobic environment together with urban sewage for hydrolysis and acidification treatment. The hydraulic retention time of the primary sedimentation tank is 0.5~2h, and the surface load is 0.8~ 1.2m 3 / m 2 h; b. In step a, the mud-water mixture after the hydrolysis and acidification treatment in the primary sedimentation tank and the sludge returned in the secondary sedimentation tank enter the anaerobic section together. The hydraulic retention time of the anaer...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the ultrasonic intensity during ultrasonic crushing in step a is 2 to 5 kw / m 3 , Ultrasonic crushing time is 5 ~ 20min. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the dosage of ozone during the ozone treatment in step a is 2-10 mg / L, and the time of ozone treatment is 5-10 min. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com