Experimental device of iron ore pellets during drying and preheating processes and method thereof

An experimental device and technology of iron ore balls, applied in the field of ironmaking production, can solve the problems of different effects and reduced oxygen partial pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

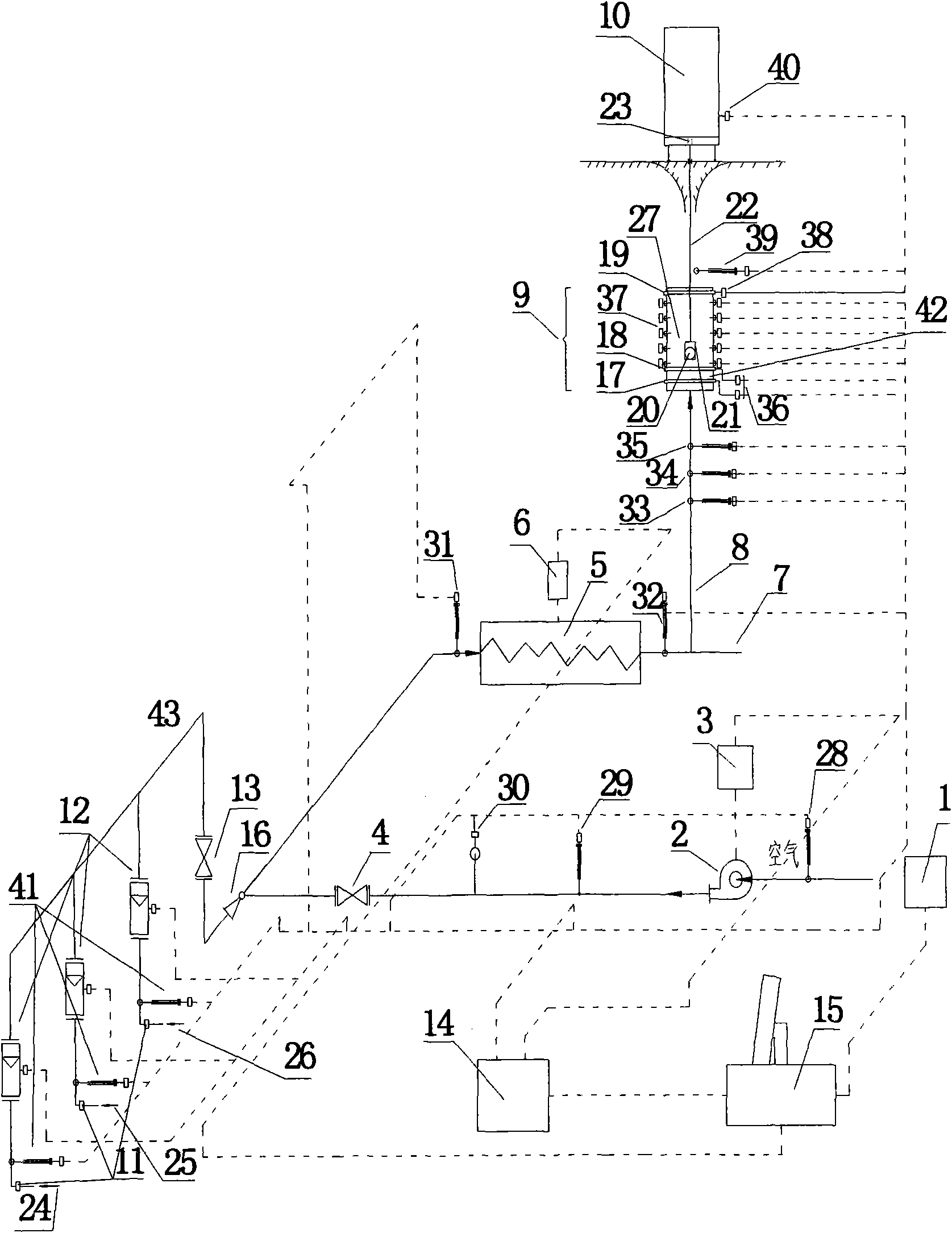

[0011] An experimental device for the drying and preheating process of iron ore pellets, comprising a humidifier 1, a fan 2, a frequency converter 3, a first valve 4, an electric heater 5, an electric heater controller 6, a cleaning port 7, and a rectifier Section 8, Experiment Section 9, Electronic Balance 10, Standard Gas Interface 11, First Flow Meter 12, Second Valve 13, Programmable Logic Controller (PLC) 14, Computer 15, Ejector 16, Front of Porous Media Air Distribution Device Pressure measuring ring chamber 17, pressure measuring ring chamber 18 after the porous medium air distribution device, pressure measuring ring chamber 19 at the exit of the experimental section, experimental pellets 20, hanging basket 21, suspension frame 22, balance modification hole 23, standard gas carbon dioxide 24. Standard gas oxygen 25, standard gas nitrogen 26, simulated flue gas 27, temperature and humidity meter 28, first thermometer 29, second flow meter 30, second thermometer 31, third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com