Amorphous alloy metallic phase corrosive agent and metallic phase display method

A technology of amorphous alloy and corrosive agent, which is applied in the direction of instruments, analytical materials, measuring devices, etc., can solve the problems of corroding the crystalline phase of amorphous alloy and the inconvenient observation of the crystalline phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

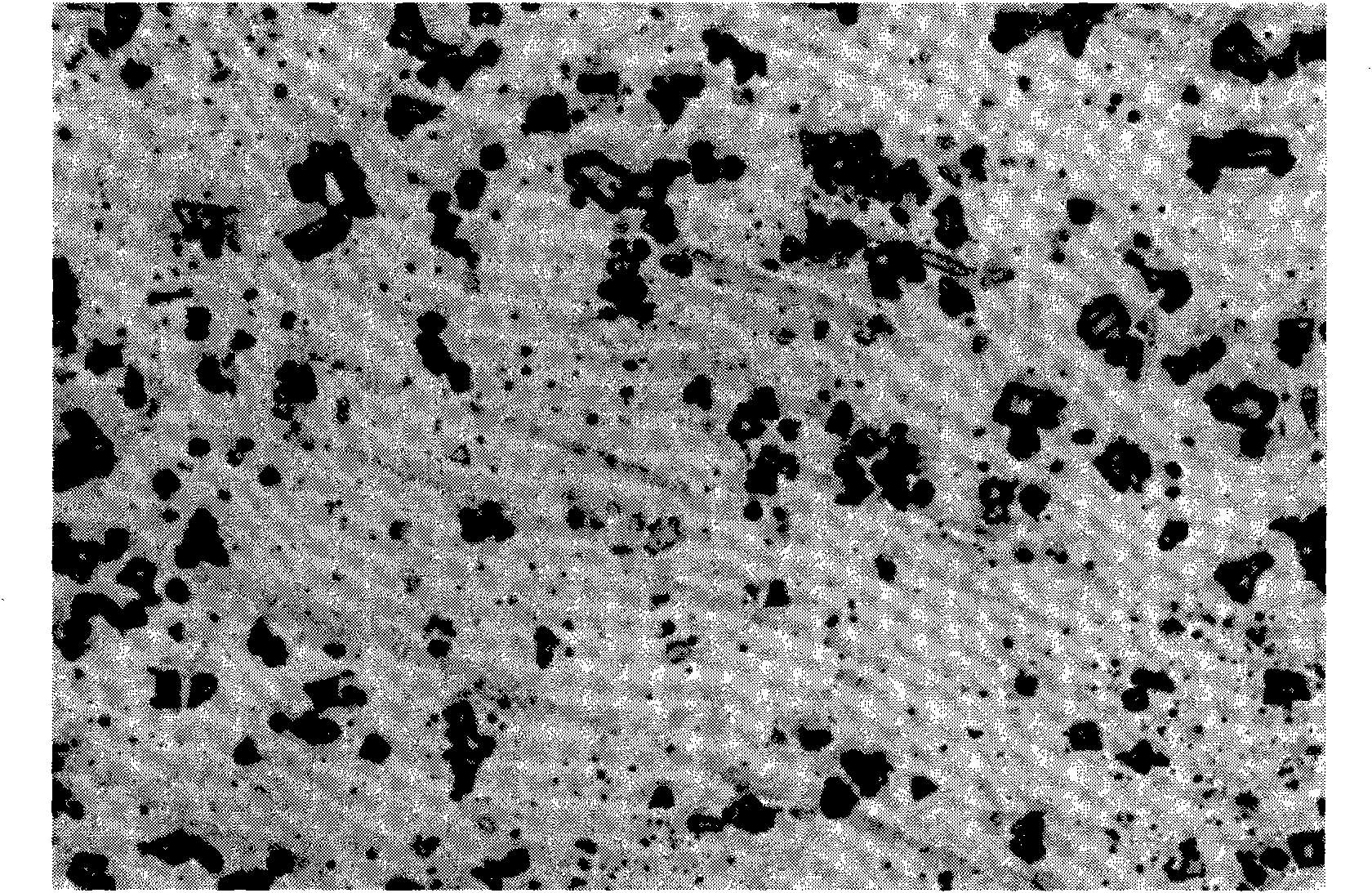

[0023] [Sample] Zr 41 Ti 14 Cu 12.5 Ni 10 be 22.5 Amorphous Alloy (U.S. Liquid Metal Technology Company)

[0024] [Formulation and process parameters]

[0025] Nitric acid content 1mol / L

[0026] Hydrochloric acid content 1.5mol / L

[0027] Sodium metabisulfite content 0.6mol / L

[0028] the rest is water

[0029] Make metallographic etchant X by above-mentioned proportioning

[0030] Corrosion time 4 minutes

[0031] temperature room temperature

[0032] [Procedures and Conditions]

[0033] Mechanical polishing→water washing→ultrasonic degreasing→water washing→electrodegreasing→water washing→drying→metallographic corrosion→cleaning (absolute ethanol)→drying

[0034] Wherein, the specific conditions of each processing step are as follows:

[0035] Mechanical polishing: yellow medium-coarse polishing paste (SBT-600 model) and white fine polishing paste (SBW-804 model) produced by Jiangmen Jielixin Polishing Materials Co., Ltd.; polishing machine produced by Dongguan ...

Embodiment 2

[0040] [sample] with embodiment 1

[0041] [processing procedure] is the same as embodiment 1

[0042] [composition and treatment condition of treatment solution] corresponding treatment solution and treatment condition are with embodiment 1,

[0043] The difference is that the metallographic etchant of the following formula is used in the metallographic corrosion process.

[0044] Nitric acid content 5mol / L

[0045] Hydrochloric acid content 0.5mol / L

[0046] Sodium metabisulfite content 0.1mol / L

[0047] the rest is water

[0048] Corrosion time 2 minutes

[0049] temperature room temperature

[0050][metallographic sample preparation] under the same preparation conditions as in Example 1, sample A2 was obtained

Embodiment 3

[0052] [Sample] Same as Example 1

[0053] [processing procedure] is the same as embodiment 1

[0054] [Composition and treatment conditions of the treatment solution] The difference from Example 1 is that the metallographic etchant of the following formula is used in the metallographic corrosion process.

[0055] [Formulation and process parameters]

[0056] Nitric acid content 2.5mol / L

[0057] Hydrochloric acid content 1mol / L

[0058] Sodium metabisulfite content 0.4mol / L

[0059] the rest is water

[0060] Corrosion time 3 minutes

[0061] temperature room temperature

[0062] [metallographic sample preparation] sample A3 is obtained under the same preparation conditions as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com