Remote monitoring and fault diagnosing system for numerical control slitter and method for realizing same

A fault diagnosis system and remote monitoring technology, applied in the general control system, control/adjustment system, program control, etc., can solve the problems of remote monitoring and fault diagnosis, disconnection, weak stability, etc., to ensure real-time Sexuality and Integrity Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

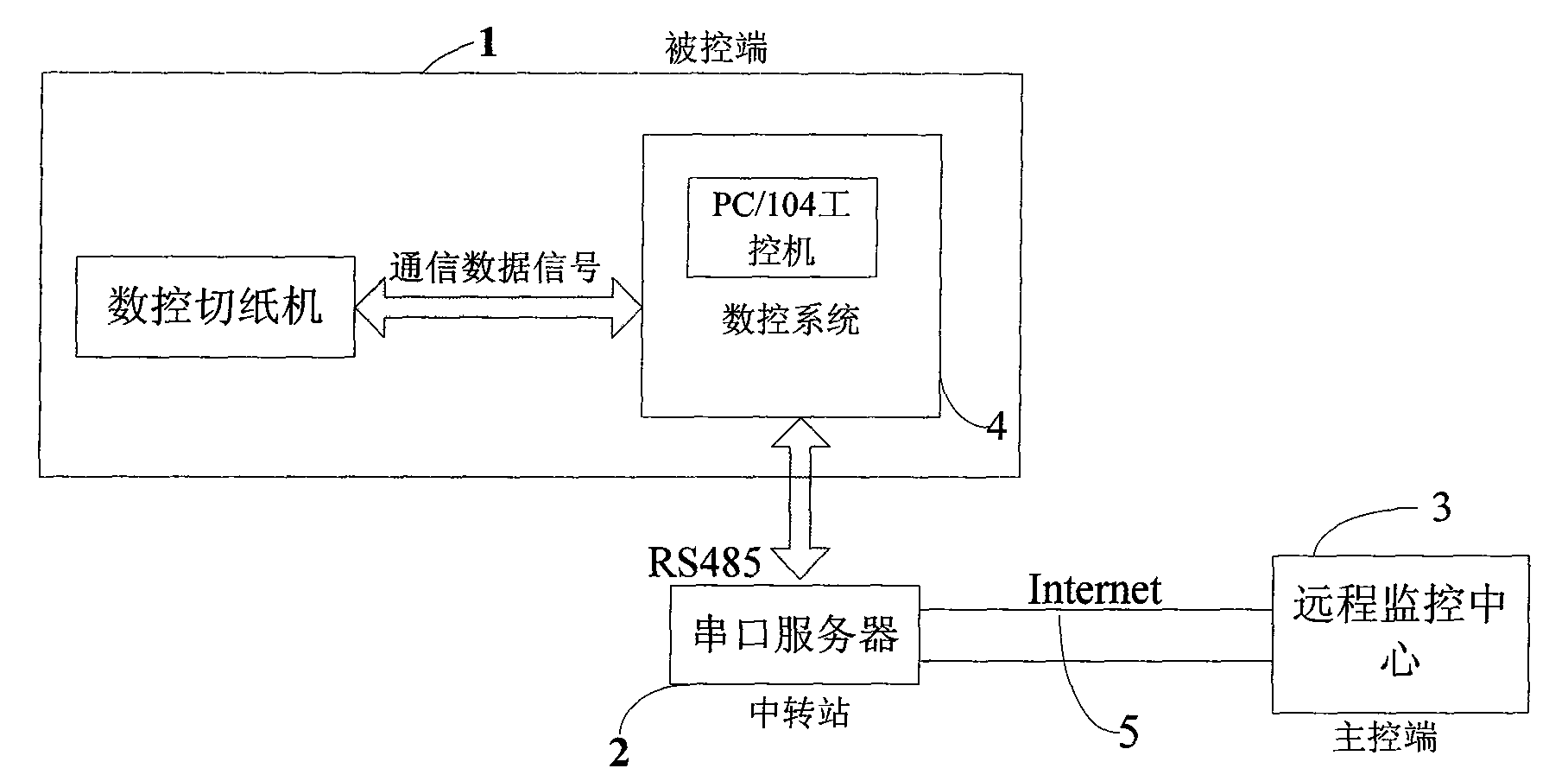

[0050] see figure 1 , a remote monitoring and fault diagnosis system for a numerically controlled paper cutter, including a controlled terminal 1 of a numerically controlled system of a paper cutter, a transfer station 2 of a serial port server, and a remote master control terminal 3 of a remote monitoring and fault diagnosis center server. The control terminal 1 is controlled by the industrial computer PC / 104, the controlled terminal 1 communicates with the transfer station 2 through the RS-485 serial port, and the transfer station 2 communicates with the remote master control terminal 3 through the Internet network.

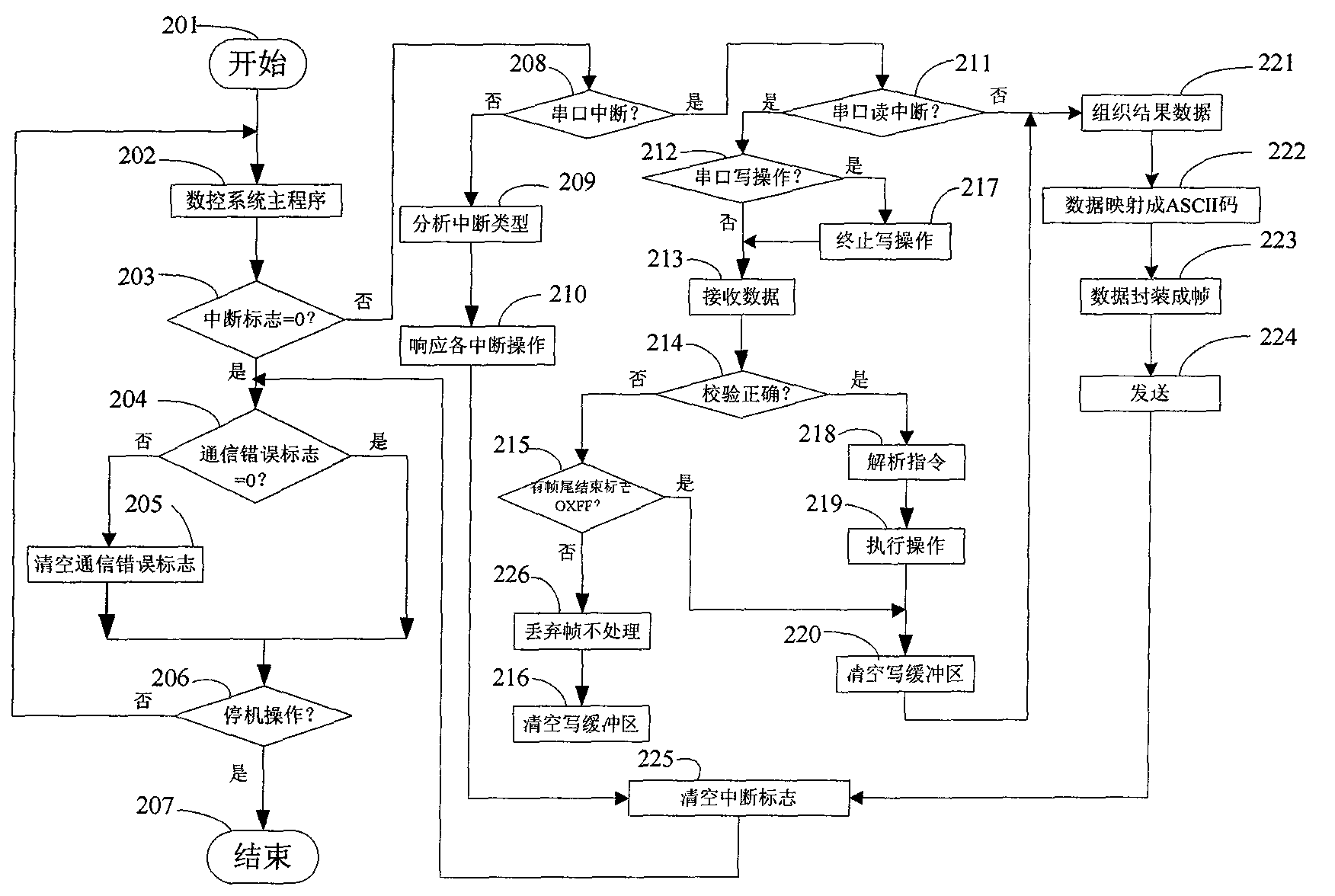

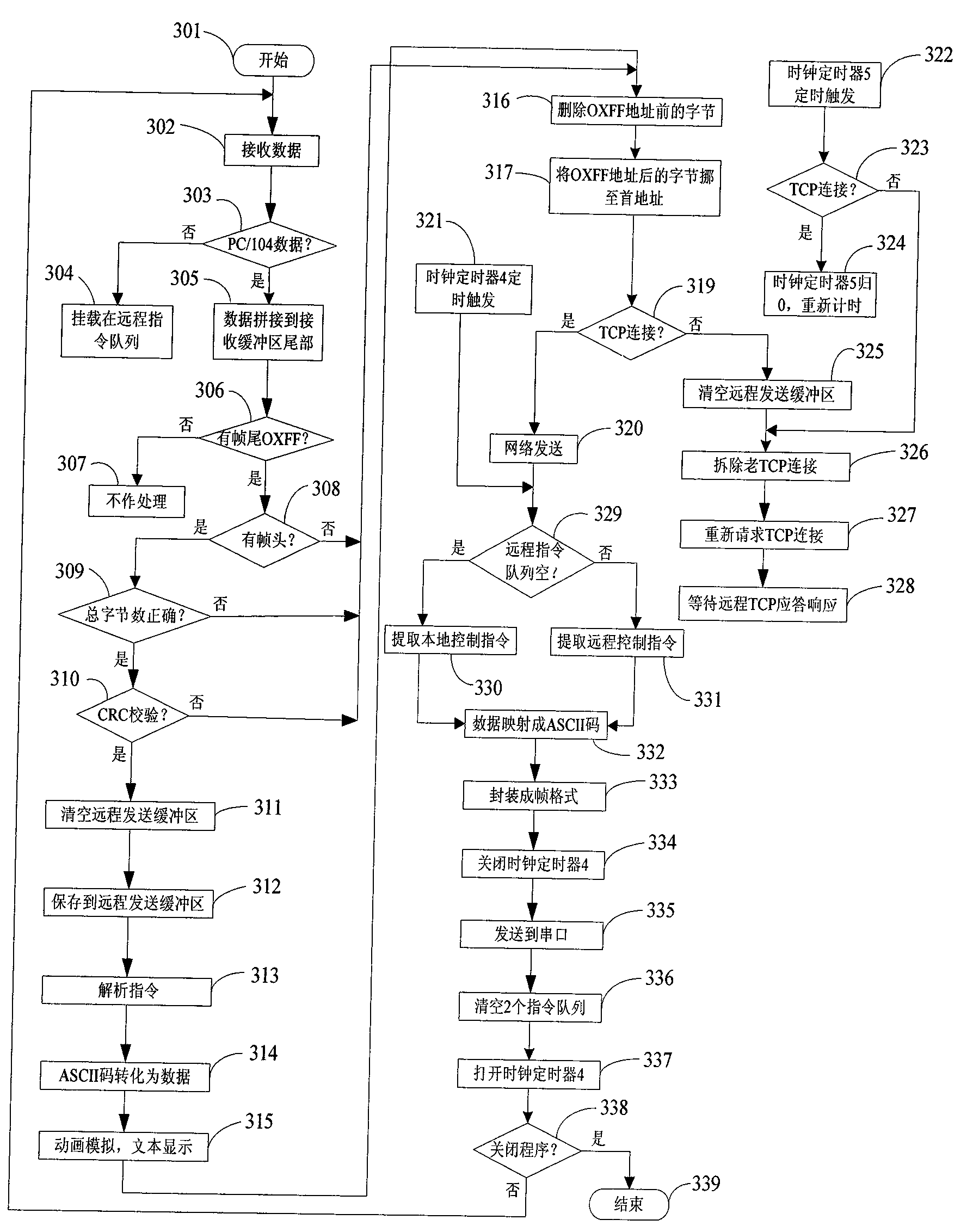

[0051]The industrial computer PC / 104 controls the operation of the CNC paper cutter, and at the same time is responsible for analyzing the control instructions of the remote monitoring center and performing related operations. After performing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com