Obstacle-crossing robot for transmission line operation and obstacle-crossing method thereof

A technology of power transmission lines and robots, applied in the field of robots, can solve the problems of high labor intensity of inspection work, difficulty in ensuring inspection arrival rate, affecting inspection quality, etc., and achieves the effects of easy programming, clear steps, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

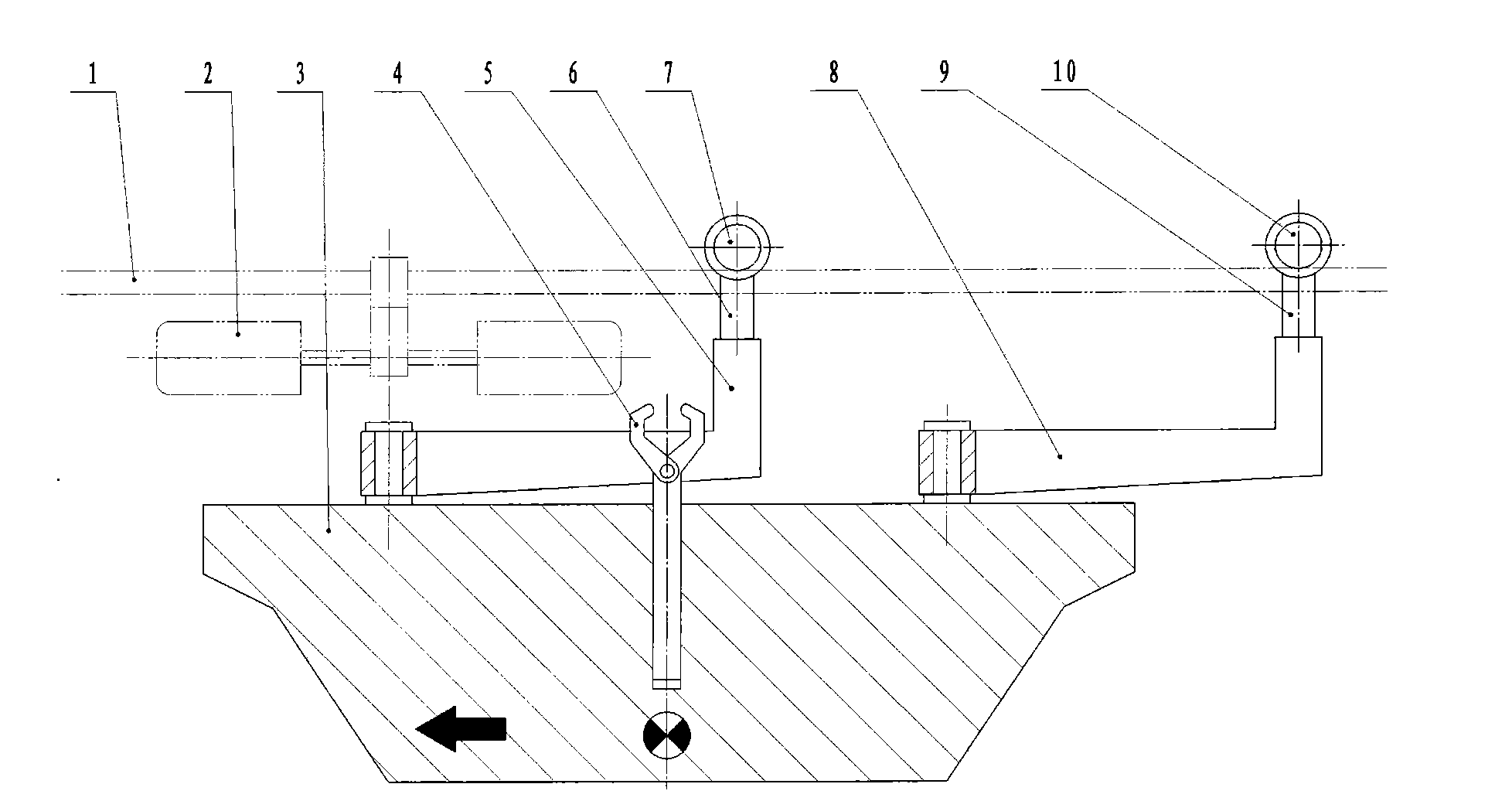

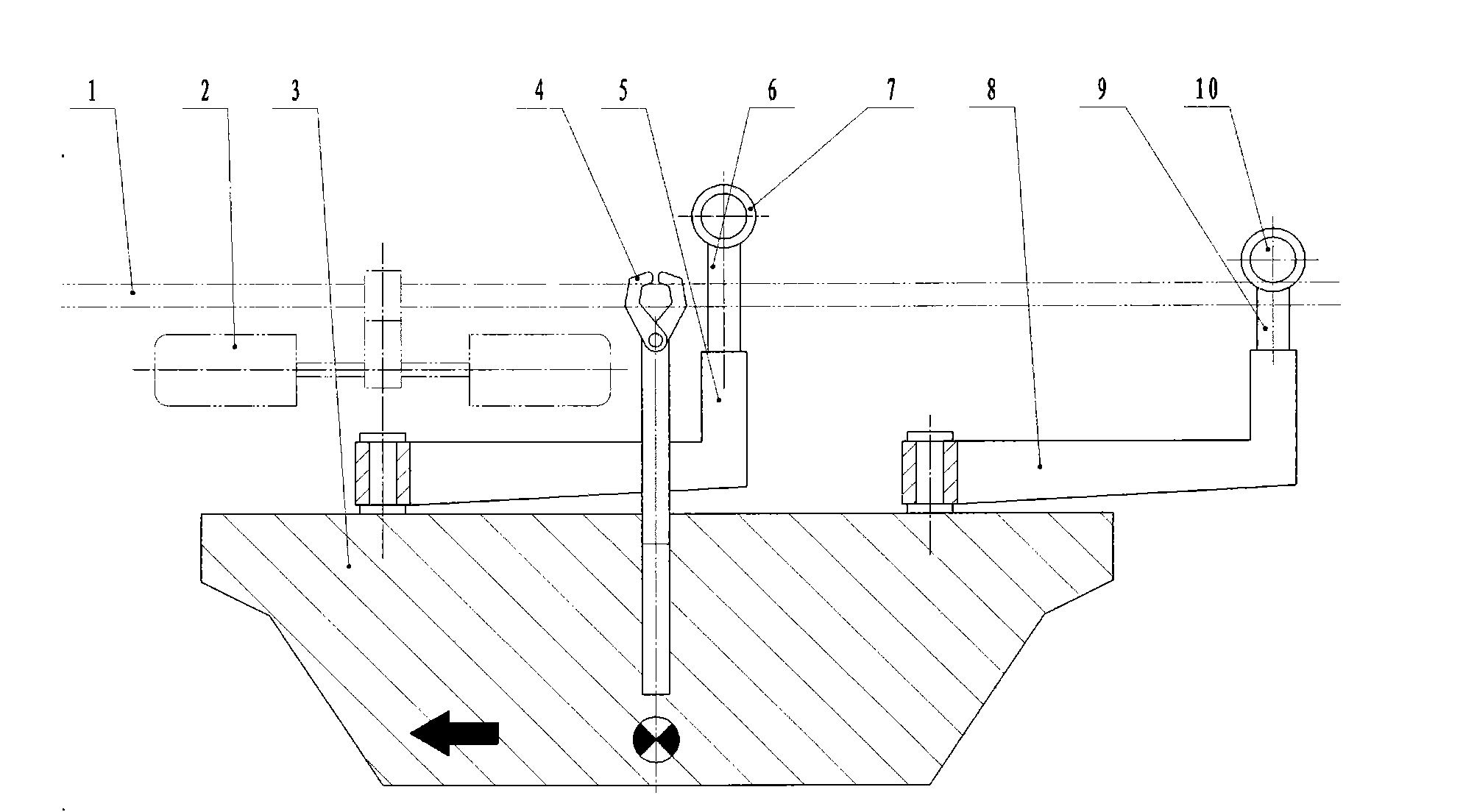

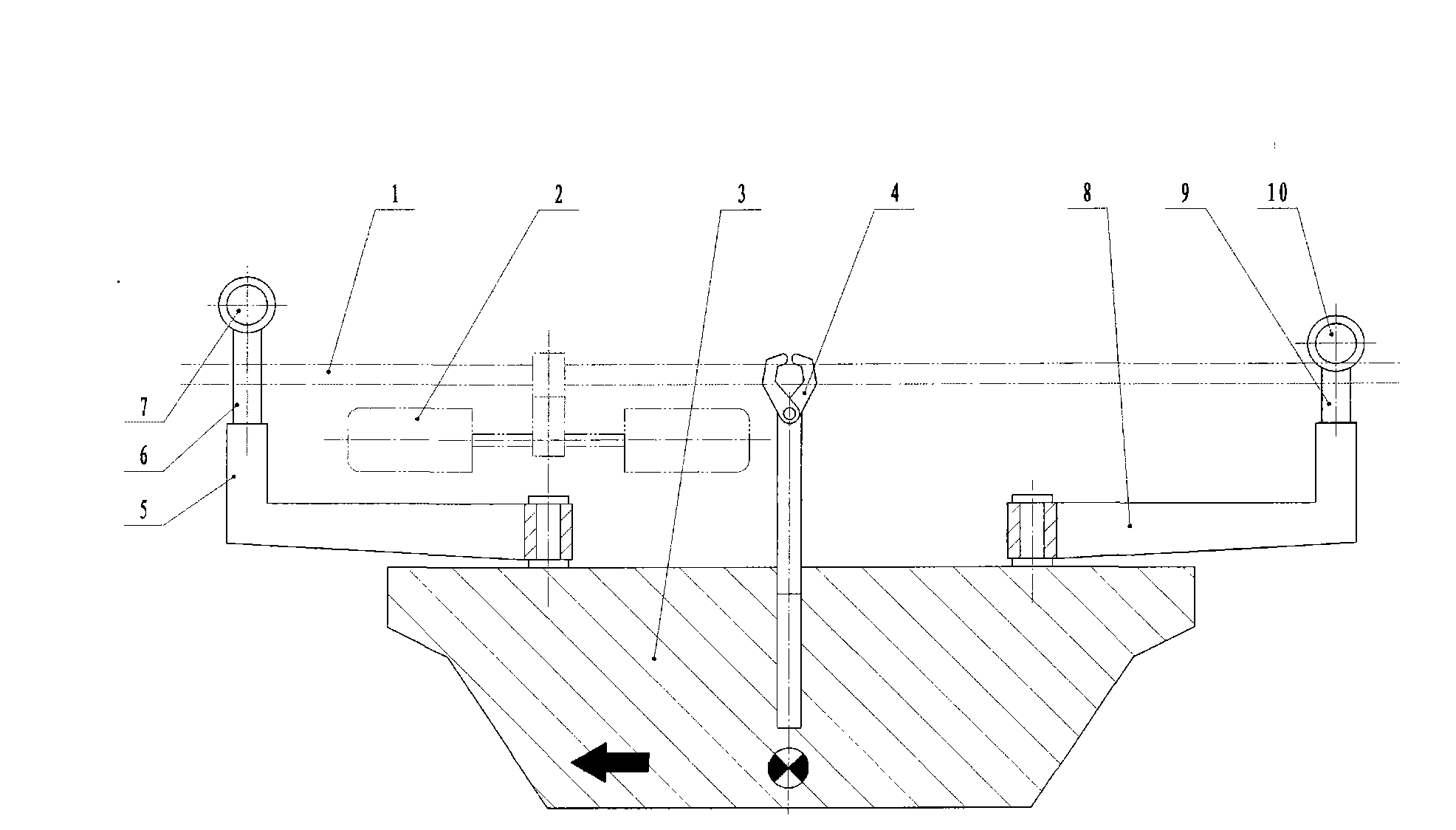

[0031] See attached figure 1 , the robot travels on the wire 1, and encounters obstacles 2 from time to time, such as spacers, anti-vibration hammers, hanging wire clamps, etc. The main body of the robot is the fuselage 3, and its center of gravity is marked with position of the symbol. Two cylindrical shafts are installed on the fuselage 3, and the front swing arm 5 and the rear swing arm 8 can rotate around these two shafts. The grooved front roller 7 is installed on the front swing arm 5 through the forearm slider 6, so that the front roller 7 can clamp or loosen the wire 1. Likewise, the grooved rear roller 10 is mounted on the rear swing arm 8 through the rear arm slider 9 , so that the rear roller 10 can also clamp or loosen the wire 1 .

[0032] The auxiliary arm 4 is installed on the axis of symmetry of the fuselage 3 . The auxiliary arm 4 can stretch out upwards and grasp the wire, and can also release the wire and retract.

[0033] Such as figure 1 When the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com