Beneficiation wastewater treatment method circularly used for ceramic filter

A technology of ceramic filter and beneficiation wastewater, which is applied in the directions of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Capillary clogging, affecting the filtering effect and other problems, to achieve the effect of reducing the amount of fresh water, good water quality, and normal filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

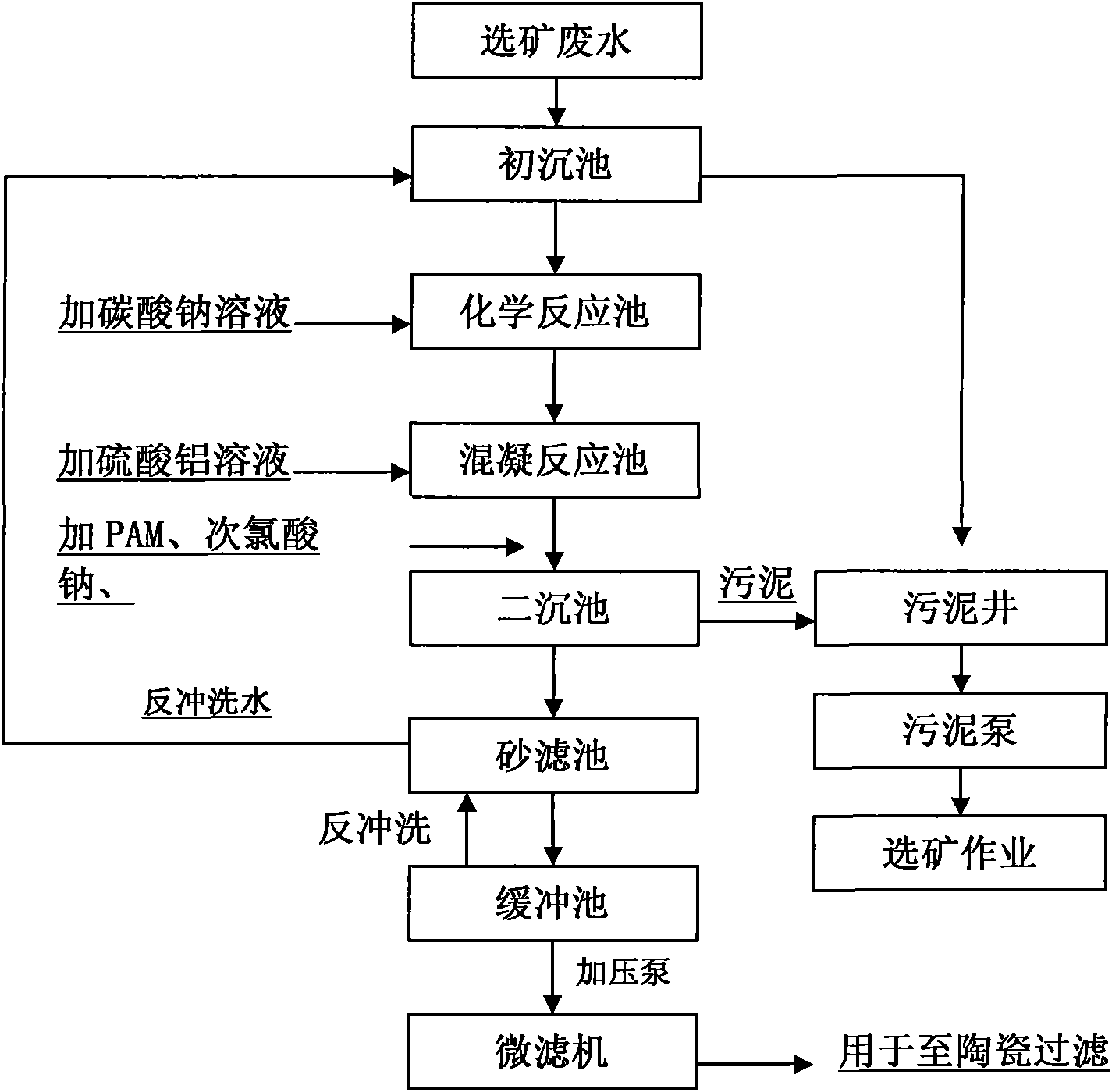

Method used

Image

Examples

Embodiment 1

[0021] Based on each liter of wastewater, 10 mg of anionic flocculant PAM, 60 mg of aluminum sulfate and a certain amount of sodium carbonate were added to the above mineral processing wastewater. When the amount of sodium carbonate per liter of wastewater is 1250-1500 mg, the calcium, magnesium ions and heavy metal ions in the wastewater are greatly reduced, and the water quality is also relatively clear.

[0022] Table 1:

[0023] Na 2 CO 3 (mg / L)

Embodiment 2

[0025] Based on each liter of wastewater, add 1500mg of sodium carbonate to the above mineral processing wastewater, mix well, and let stand for 20 minutes, then add a certain amount of aluminum sulfate and 10mg of anionic flocculant PAM, mix evenly, let stand for 20 minutes After sampling and analysis, the processing results are shown in Table 2. It can be seen from Table 2 that aluminum sulfate has no effect on the removal of Ca ions and Mg ions in wastewater, but it can remove a large amount of heavy metal ions. When the amount of aluminum sulfate per liter of wastewater is 30 mg, the effect is the best, and the effluent becomes clear transparent.

[0026] Table 2:

[0027] Aluminum sulfate

Embodiment 3

[0029] Based on each liter of waste water, add 1500mg of sodium carbonate to the above mineral processing waste water, mix well and let it stand for 20 minutes, then add 30mg of aluminum sulfate and a certain amount of anionic flocculant PAM, mix well and let stand for 20 minutes Sampling analysis, processing results are shown in Table 3. It can be seen from Table 3 that the effect of flocculant PAM on Ca in wastewater 2+ , Mg 2+ , Pb 2+ , Zn 2+ Both have a certain reduction effect, mainly to accelerate the precipitation of particles that are not compatible with water, and at the same time make heavy metal ions flocculate and precipitate. The best effect is when the amount of PAM per liter of wastewater is 10mg.

[0030] Flocculant (mg / L)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com