Washing agent and washing method for paraffin removal and unplugging of oil wells and oil pumping pipelines of oil fields

A technology for oil pumping pipeline and cleaning agent, which is used in the field of cleaning oil wells and pipelines, oil wells in oil fields, cleaning agents for removing wax and blockage of oil pumping pipelines, and cleaning agents, can solve problems such as high cost and large pollution, and reduce water content. , The effect of prolonging the wax deposition period and reducing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to the mass percentage of 85%: 10%: 5%, take by weighing spherical aluminum powder, powdery sodium gluconate and powdery dodecyl hydroxyl with a particle size of 28.76 μm, and mix them evenly to obtain heat-generating powder; The heat generating powder is stirred into a paste with a small amount of crude oil, and injected into the oil well from the annulus of the oil well pipeline; the oil well pipeline is washed with 30 to 50 liters of water; 10% sodium hypochlorite solution and 96% ionic alkali solution are mixed evenly to obtain a cleaning agent; according to the mass percentage of heat generating powder: cleaning agent=1:25, the cleaning agent is weighed and injected into the annulus of the oil well pipeline. in the oil well.

Embodiment 2

[0030] According to the mass percentage of 90%: 8%: 2%, take by weighing spherical aluminum powder, powdery sodium gluconate and powdery dodecyl hydroxyl with a particle size of 28.76 μm, and mix them evenly to obtain heat-generating powder; The heat generating powder is stirred into a paste with a small amount of water, and injected into the oil well from the annular space of the oil well pipeline; the oil well pipeline is washed with 30-50 liters of water; 14% sodium hypochlorite solution and 100% ionic alkaline solution are mixed evenly to obtain a cleaning agent; according to the mass percentage of heat-generating powder: cleaning agent=1:50, the cleaning agent is weighed and injected into the annulus of the oil well pipeline. in the oil well.

Embodiment 3

[0032] According to the mass percentage of 80%: 15%: 5%, take by weighing spherical aluminum powder, powdery sodium gluconate and powdery dodecyl hydroxyl with a particle size of 28.76 μm, and mix them evenly to obtain heat-generating powder; The heat generating powder is stirred into a paste with a small amount of water, and injected into the oil well from the annular space of the oil well pipeline; the oil well pipeline is washed with 30-50 liters of water; 13% sodium hypochlorite solution and 99% ionic alkali solution are mixed evenly to obtain a cleaning agent; the cleaning agent is weighed according to the mass percentage heat generating powder: cleaning agent = 1:35, and injected into the oil well from the annular space of the well pipeline middle.

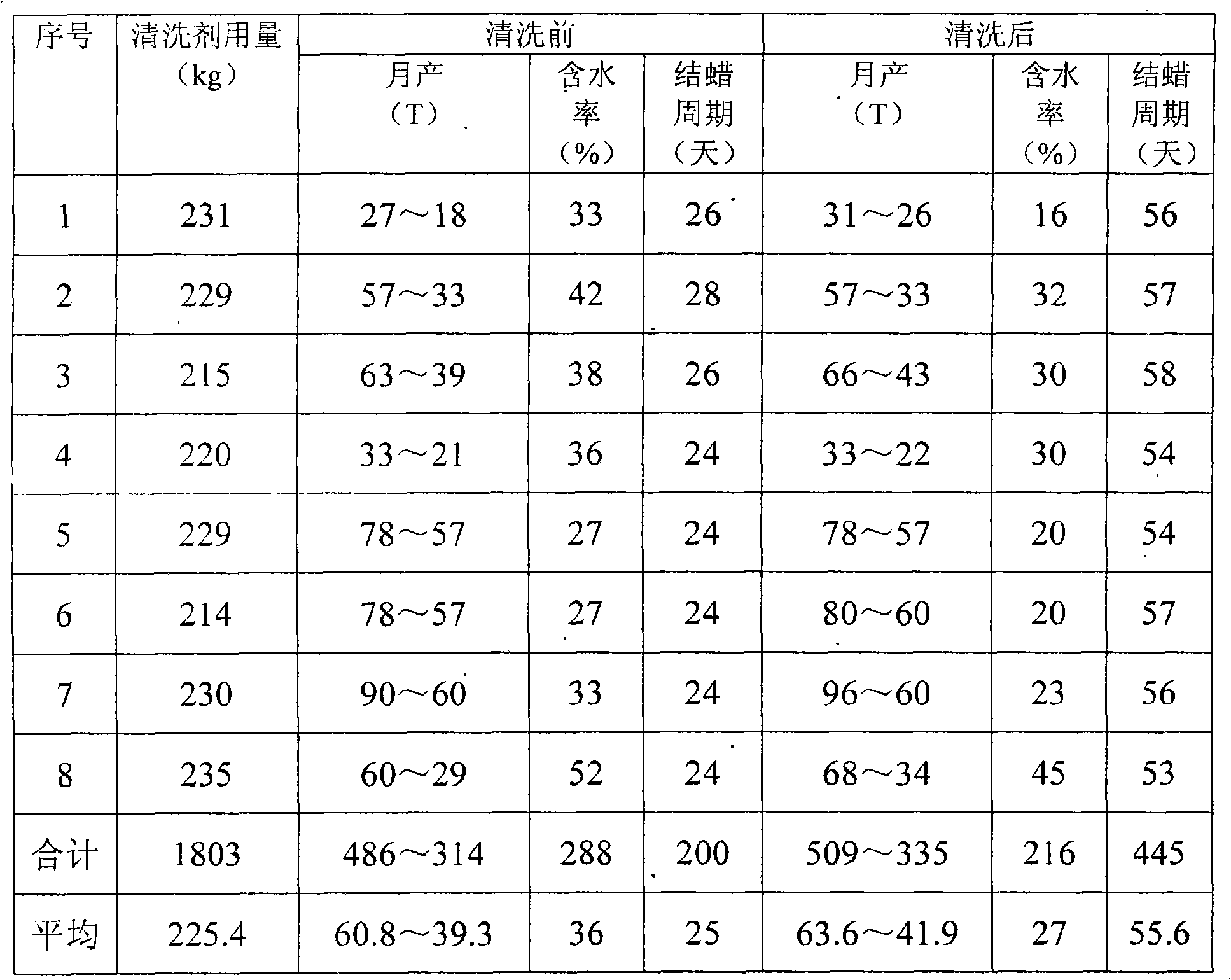

[0033] Table 1 is to adopt cleaning agent of the present invention to clean oil well pipeline, the oil well condition before cleaning and the oil well condition comparison after cleaning:

[0034] Table 1 Comparison table o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com