System and method for automatically processing and/or machining workpieces

A technology of mechanical processing and automatic machinery, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that the date of automatic adjustment cannot be properly specified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

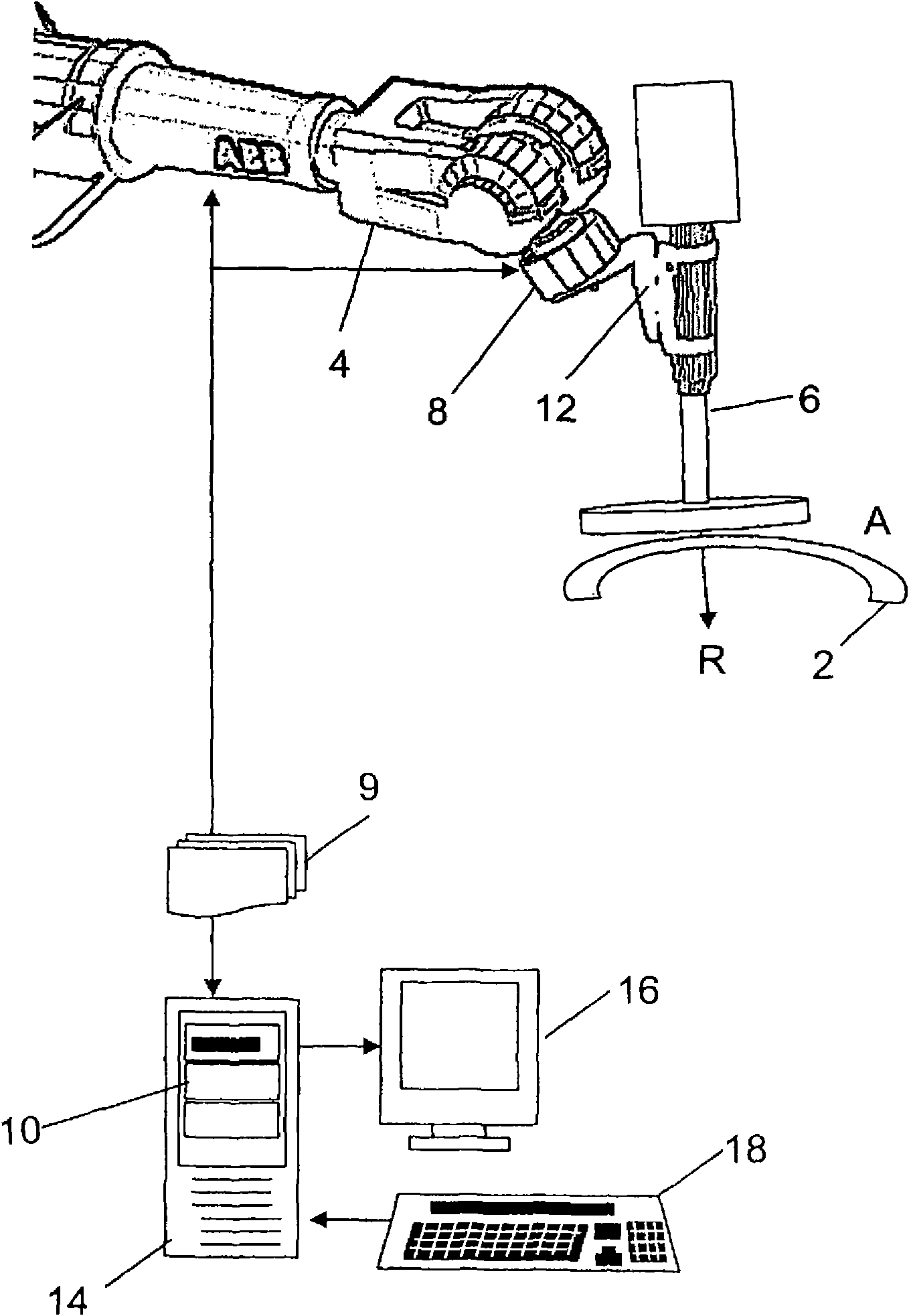

[0085] figure 1 An example system design for automated machining and / or handling of workpieces is shown. The processing device 4 provided is a multi-axis robot or industrial robot, in particular a six-axis robot, having at least one measuring device 8 with at least one force sensor for recording at least one controlled variable 9 .

[0086] The end of the robot 4 is provided with a holding device 12 for holding at least one tool 6 , in the example shown here a grinder or grinding mechanism. For example, the holding device 12 may have a flange and / or grippers and / or a changing magazine for tools.

[0087] In particular, however, other processing tools may also be used, for example in particular grinding and / or milling and / or deburring tools and / or welding machines.

[0088] Furthermore, an adjustment device 10 is provided, which is combined with the measuring device 8 and takes into account at least one controlled variable 9 in order to make the individual machining and And / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com