Dry method mechanism building aggregate grading method and device

A grading method and aggregate technology, applied in the field of construction sand making, to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

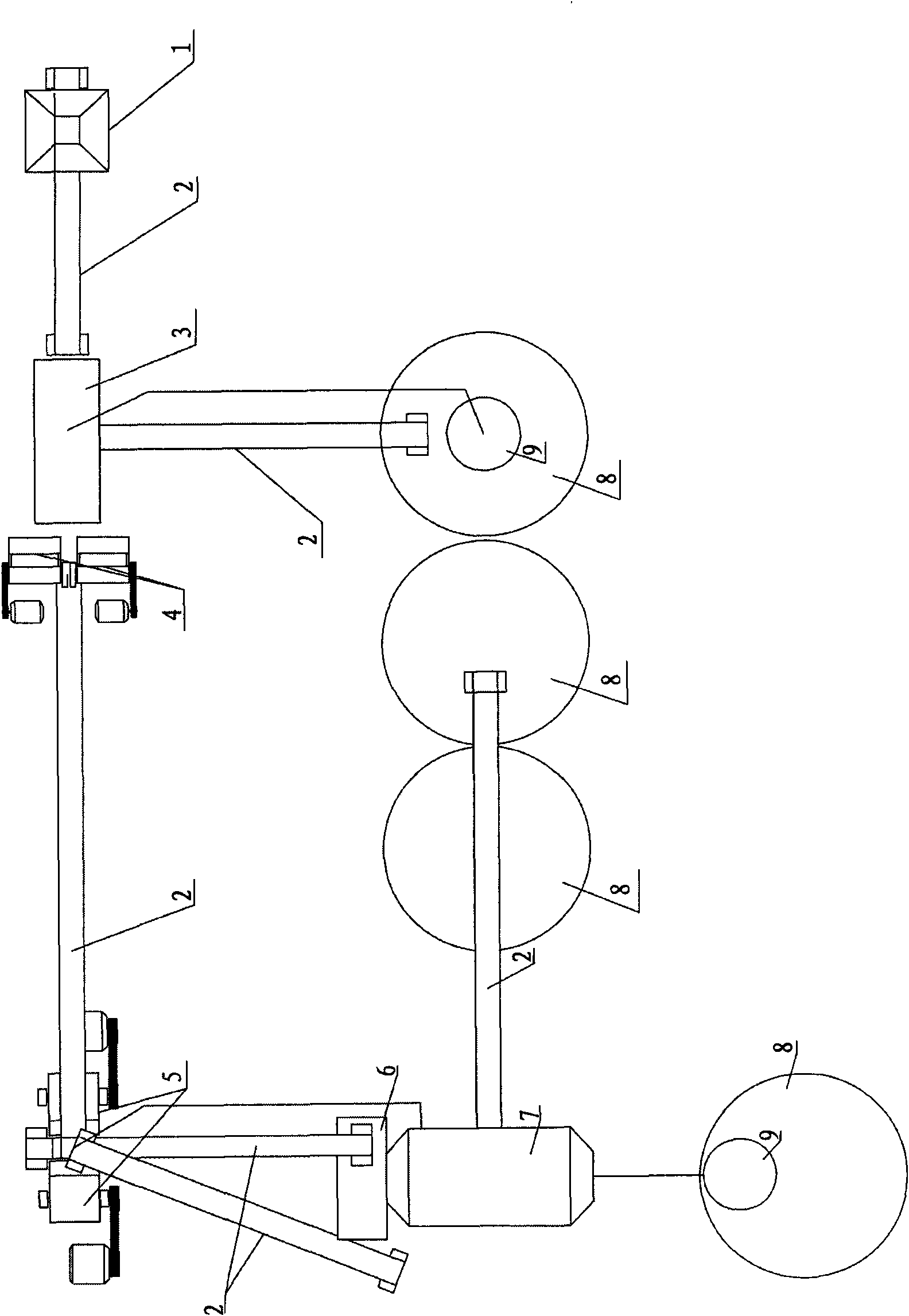

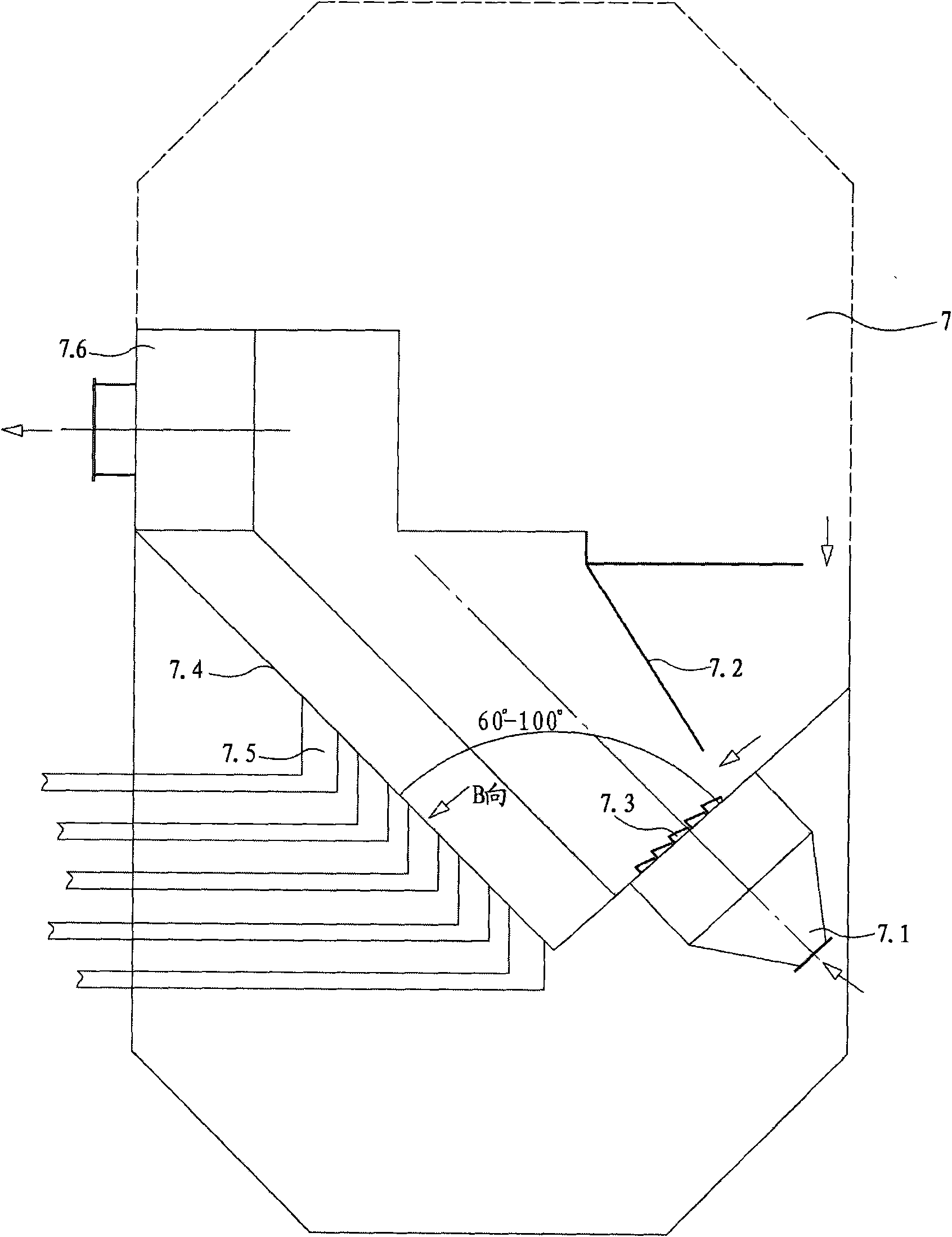

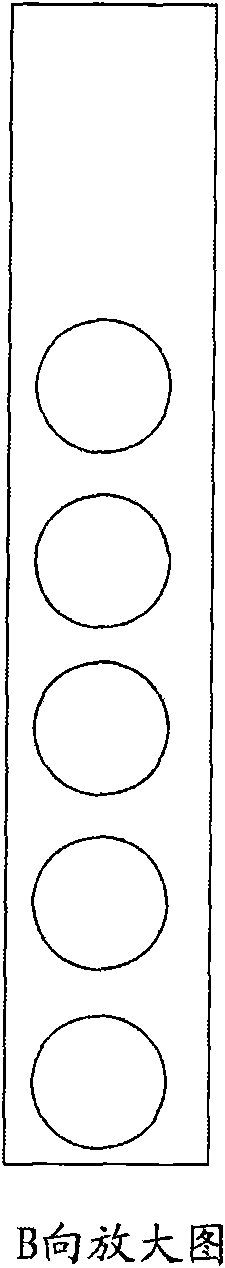

[0031] Refer to attached figure 1 with 2 , Limestone, granite and river pebbles of different particle sizes are selected as raw materials for sand making. The raw material conveyor 2 sends the above-mentioned raw materials in the storage bin 1 to the impurity separator 3 for impurity separation, and then enters the jaw pre-crusher 4 to pre-crush the separated stone raw materials to a size range smaller than about 80mm, and then passes through The raw material conveyor 2 sends it to the fine crusher 5 for sand making, and the raw material smaller than about 80 mm is crushed to smaller than about 25 mm by the fine crusher 5, and is transported to the finished product screening machine 6, and the finished product screening machine 6 screens out the raw materials smaller than about 5 mm. The sand powder is also sent into the finished product classifier 7; the distribution plate 7.3 of the present embodiment is connected at an angle of 85 degrees with the classifying plate 7.4, an...

Embodiment 2

[0033] Refer to attached figure 1 with 2 , choose basalt and tailings of different particle sizes as raw materials for sand making. The raw material conveyor 2 sends the above-mentioned raw materials in the storage bin 1 to the impurity separator 3 for impurity separation, and then enters the hammer crusher 4 to pre-break the separated stone raw materials to a size range smaller than 80mm, and then conveys them through the raw material The machine 2 sends it to the rod mill sand making machine 5 for sand making, and uses the rod mill sand making machine 5 to crush the raw materials less than 80 mm to less than 25 mm, and transports them to the finished product screening machine 6, and the finished product screening machine 6 screens out The sand powder less than 5mm is sent into the finished product classifier 7; the distribution plate 7.3 of the present embodiment is connected with the classifying plate 7.4 at an angle of 70 degrees, and the air volume is 2504m 3 / h Blower ...

Embodiment 3

[0035] Refer to attached figure 1 with 2 , Granite, river pebbles and tailings of different particle sizes are selected as raw materials for sand making. The raw material conveyor 2 sends the above-mentioned raw materials in the storage bin 1 to the impurity separator 3 for impurity separation, and then enters the impact crusher 4 to pre-break the separated stone raw materials to a size range less than about 80mm, and then passes through The raw material conveyor 2 sends it to the impact sand making machine 5 for sand making, and the impact sand making machine 5 crushes the raw materials smaller than about 80 mm to about 25 mm, and transports them to the finished product screening machine 6, and the finished product screening machine 6 Sieve out the sand powder less than about 5mm and send it into the finished product classifier 7; the distribution plate 7.3 of this embodiment is connected with the classifying plate 7.4 at an angle of 90 degrees, and the air volume is 2100m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com