Driving device for controlled displaceable carriages

A driving device and controlled technology, which is applied in the direction of feeding device, electromechanical device, and mechanical energy control, can solve the problems of bearing scrapping and high temperature rise, and achieve the effects of reduced manufacturing cost, reduced weight, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

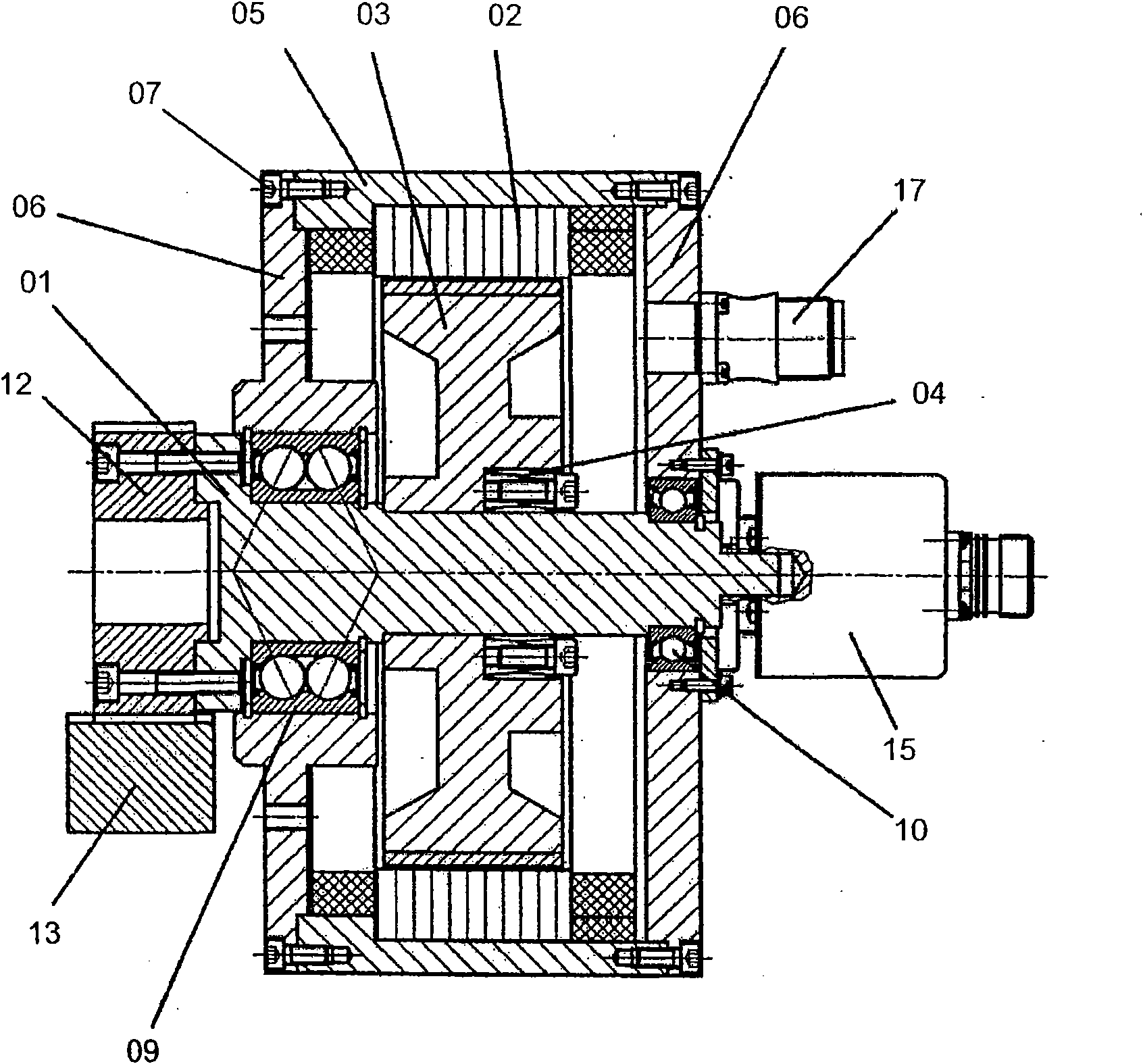

[0027] figure 1 The shown drive according to the invention is used for the controlled movement of the not shown slide of the machine tool relative to the machine bed.

[0028] The drive means comprises an electric motor with a stator 02 and a rotor 03 arranged on a shaft 01 . Torque motors are preferably used as electric motors. The rotor 03 is supported by the shaft 01 and is centered on said shaft 01 by a cylinder of greater length. In this way, rotor 03 can be centered sufficiently precisely with minimal radial runout errors. The rotor 03 is fixed and clamped on the shaft 01 by means of the clamping assembly 04 . This ensures a slip-free torque transmission.

[0029] The electric motor is preferably arranged in a cooling jacket 05 surrounding the stator 02 . The electric motor is closed on both sides by means of a housing plate 06 . The shell plate 06 is fixedly connected to the cooling jacket 05 through a mechanical connector 07 . Recesses for receiving the two roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com