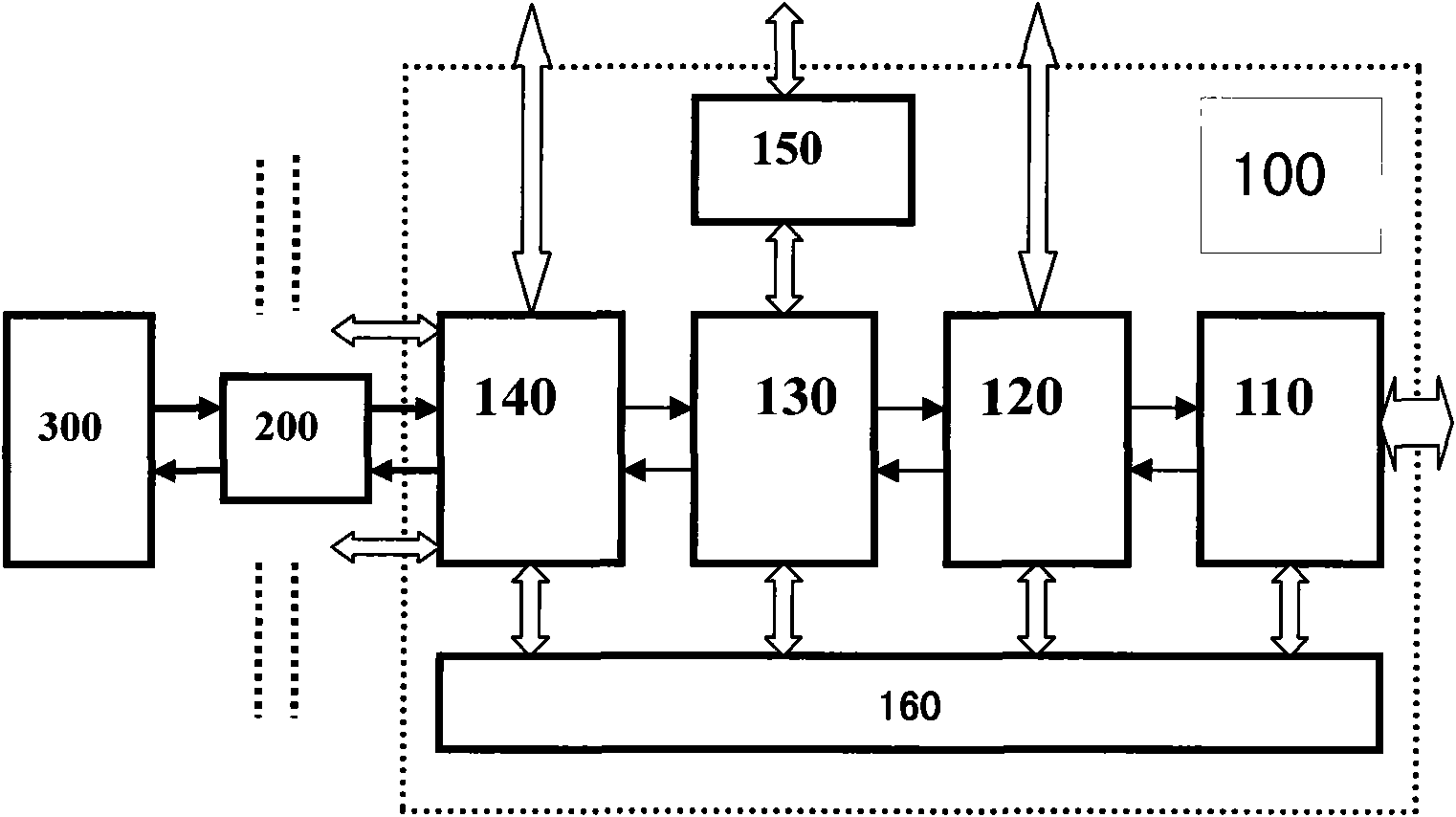

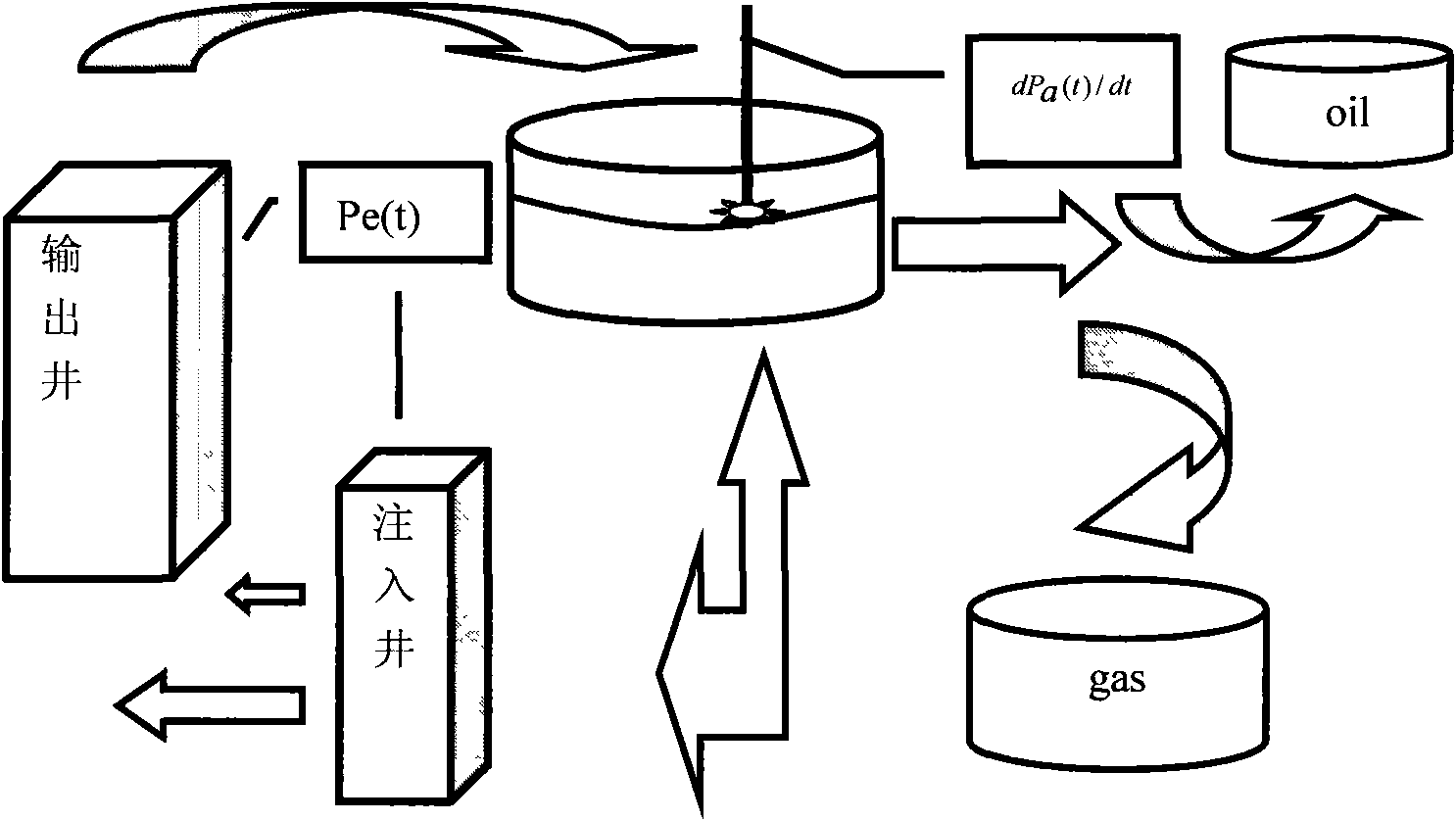

Energy saving and efficiency increasing system for output well and (or) injection well

A well condition and well formation technology, applied in the field of energy-saving and efficiency-enhancing systems, can solve problems such as pump leakage, shortened equipment life, and oil rod breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

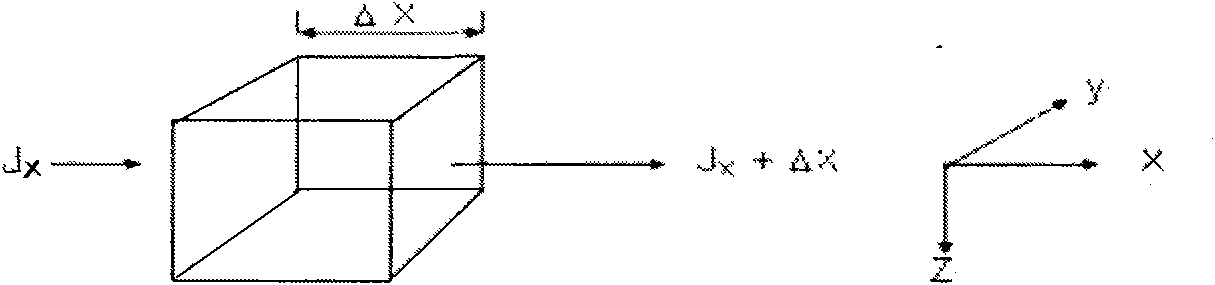

[0026] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention. This project adopts intelligent energy-saving frequency modulation technology measures, which optimize the relationship between the working efficiency of oil production pumps and water injection pumps in oil fields and the working conditions of wells (well conditions). Use software to realize fuzzy mathematical arithmetic operations, issue control commands accurately, change the operating curve of the inverter or improve the performance of the inverter; it can also timely control the valves, packers, water nozzles and other actuators at the wellhead or in the well. It not only improves the power saving rate, but also increases the production capacity of crude oil, so that the unit production capacity of the oil field can be improved on the original basis, and the energy saving rate can reach more than 30%.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com