Air compressor

An air compressor and air pump technology, applied in the field of air compressors, can solve problems such as low service life, low efficiency of air compressors, and high noise, and achieve the effects of reducing noise, facilitating restarting, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

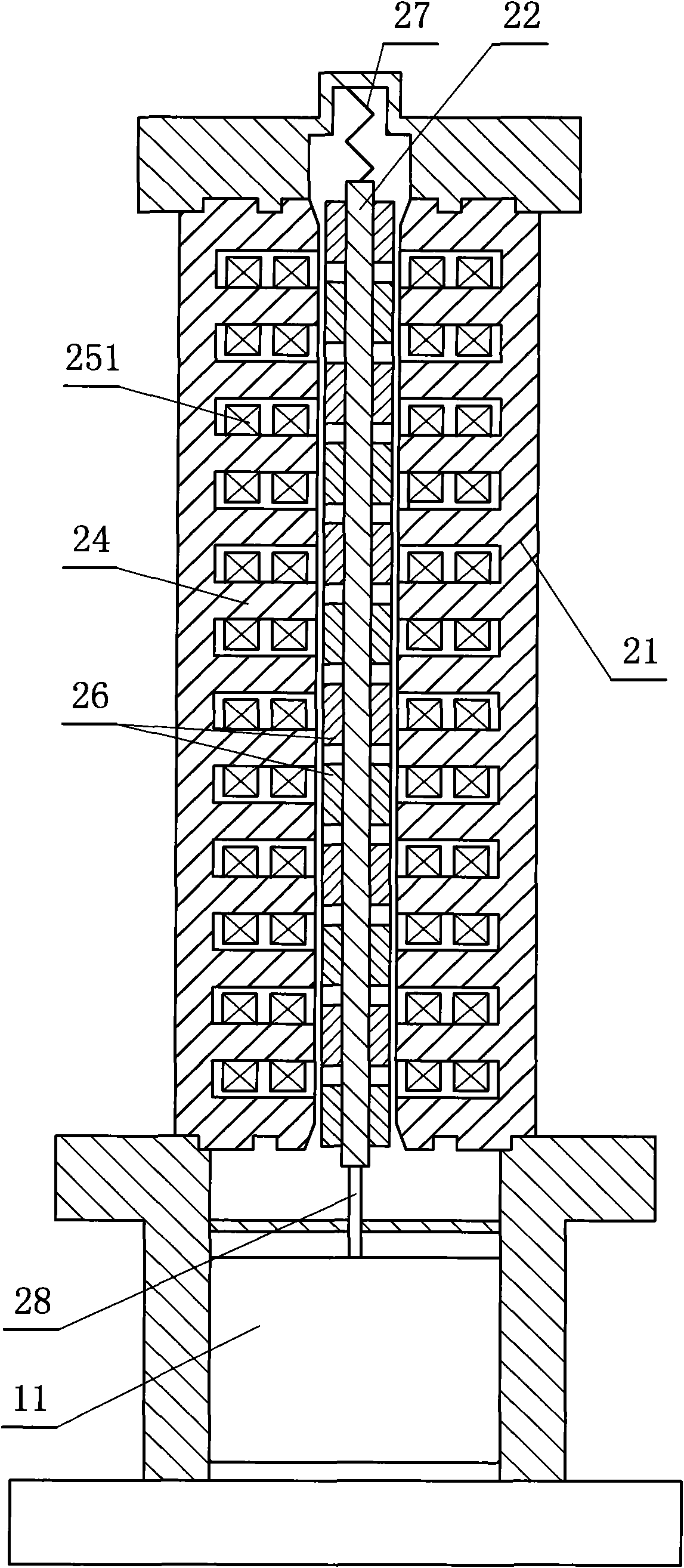

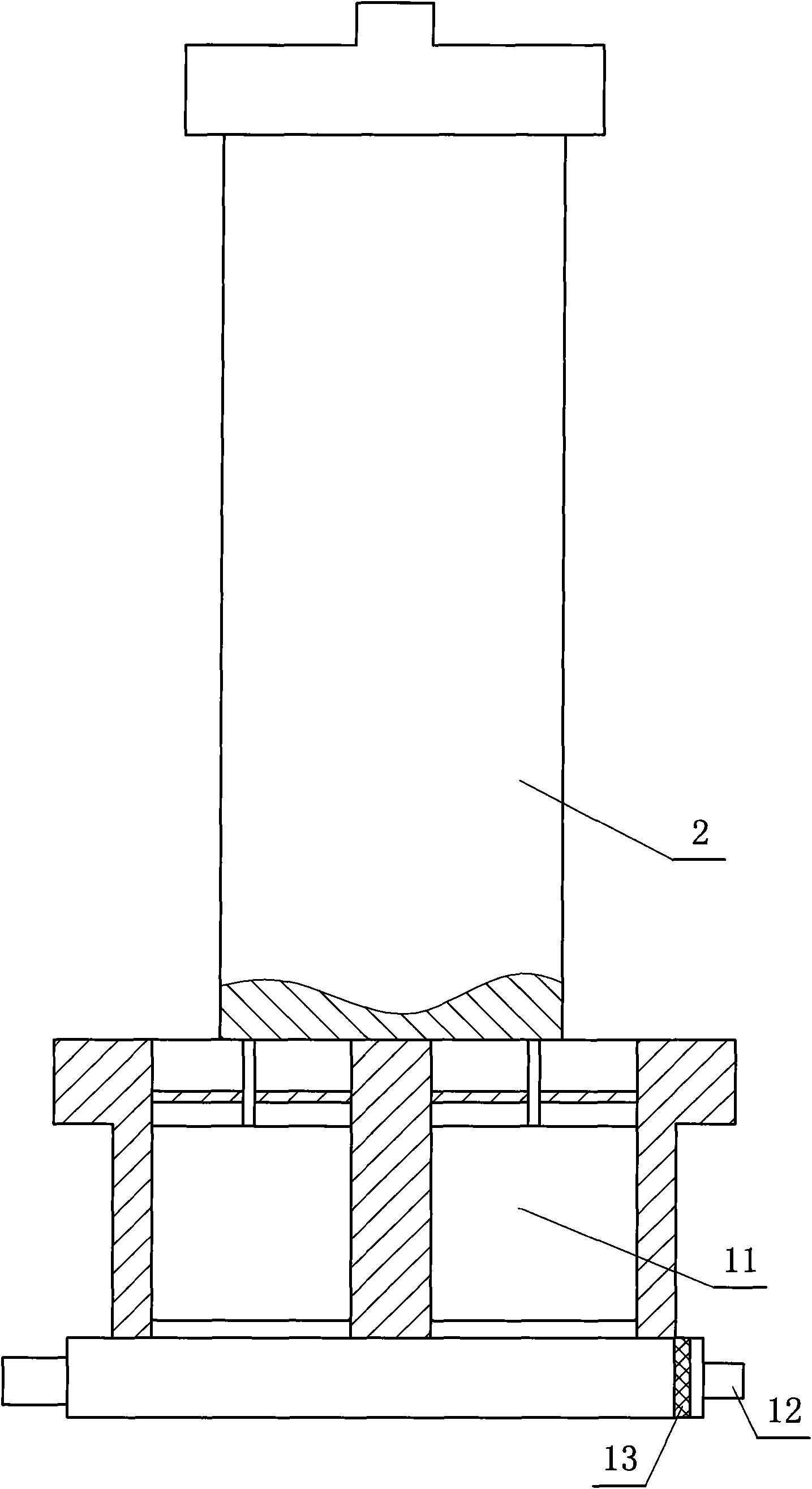

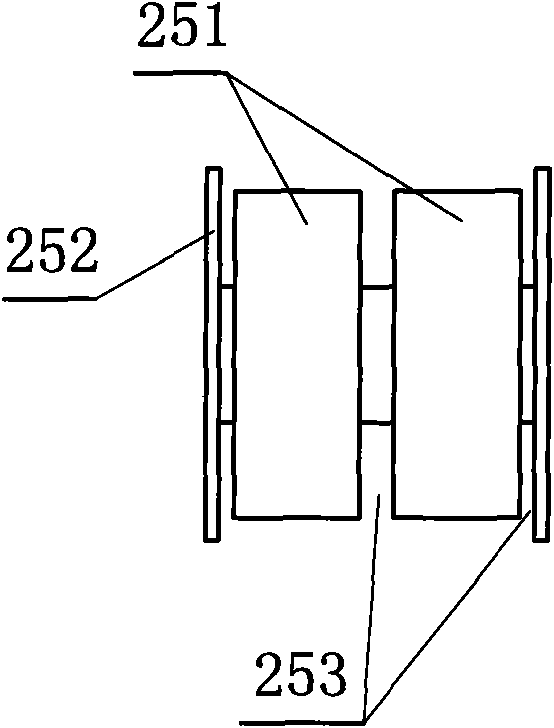

[0025] refer to figure 1 , figure 2 Embodiment 1 of an air compressor of the present invention, an air compressor includes an air pump 1, a piston 11 and an air filter 13 arranged at the air inlet 12 are arranged in the air pump 1, and a motor 2. The motor 2 includes a stator 21 and a magnetic core yoke 22. A through hole 23 is provided in the center of the stator 21, and at least one set of stator cores 24 perpendicular to the axis of the through hole 23 are arranged on the wall of the through hole 23. The stator core 24 is provided with an electromagnetic coil 251, the magnetic core yoke 22 is provided with two or more pairs of magnetic steel 26, the magnetic steel 26 N poles and S poles are arranged alternately, and the magnetic core yoke 22 is arranged in the through hole 23, one end of the magnetic core yoke 22 is provided with two connecting rods 28 connected to the piston 11 of the air pump 1, and the other end of the magnetic core yoke 22 is provided with a compressi...

Embodiment 2

[0027] refer to Figure 6 It is the second embodiment of an air compressor of the present invention. An air compressor includes two air pumps 1, the connection with one of the air pumps 1 and the internal and external structure of the motor 2 are the same as in the first embodiment, and the magnetic core yoke 22 The other end of the connecting rod 28 is also provided with at least one connecting rod 28 to be connected with the piston 11 of the second air pump 1, the compression spring 27 is sleeved on the connecting rod 28, one end of the compression spring 27 withstands the magnetic core yoke 22, and the other end of the compression spring 27 Hold the shell of the air pump 1.

[0028] When in use, connect the pipelines of the air inlet 12 and the air outlet, and energize the motor 2. After the electromagnetic coil 251 inside the motor 2 is energized, the magnetic poles generated continuously change, and the magnetic steel 26 on the magnetic core yoke 22 acts to promote The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com