Combustion device for biomass granular fuel

A biomass particle and combustion device technology, applied in the direction of solid fuel combustion, combustion equipment, lighting and heating equipment, etc., can solve the problems of low combustion efficiency, high smoke and dust, easy coking, etc., achieve high dust removal efficiency and reduce dust removal load , the effect of preventing low temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

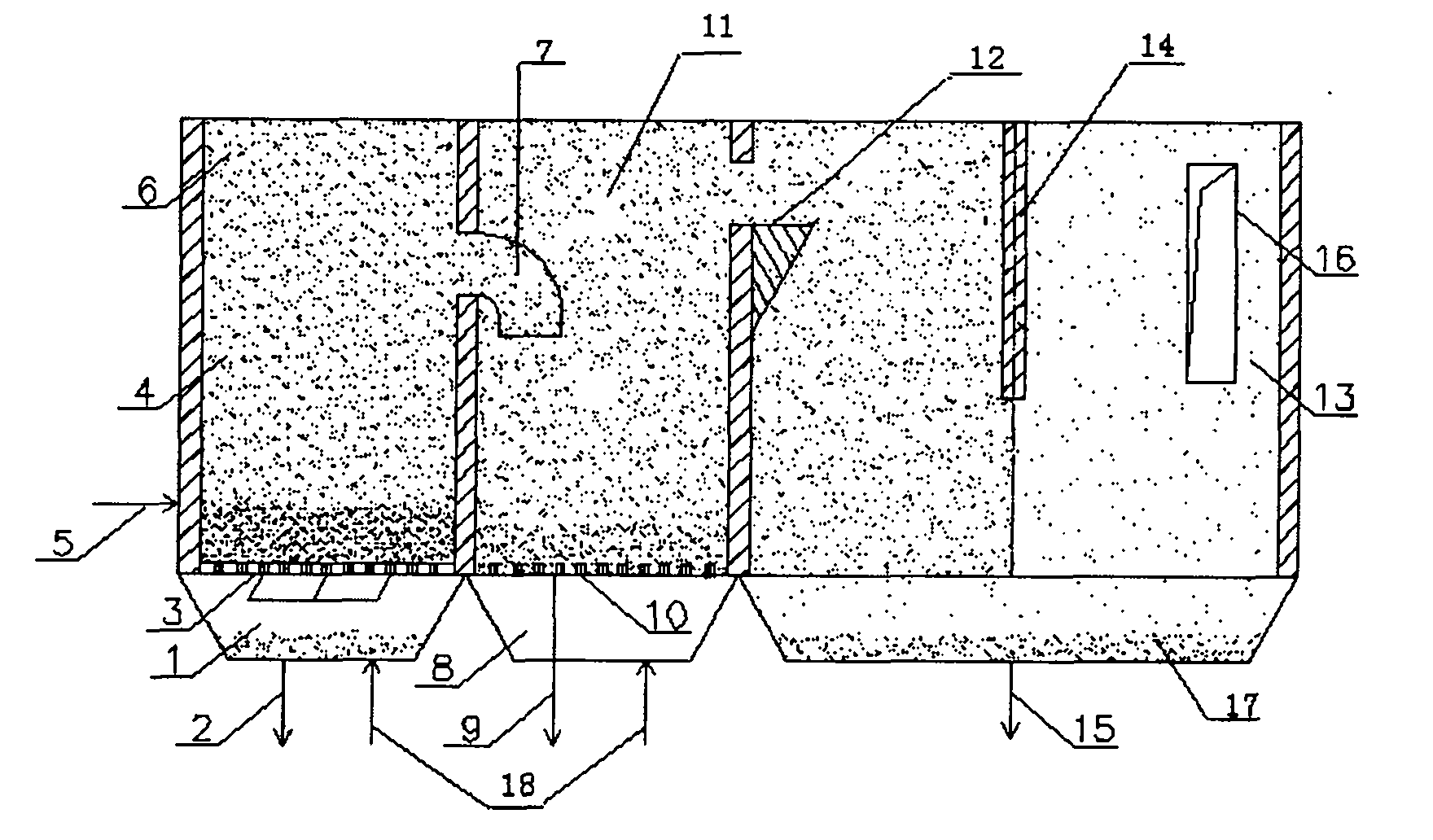

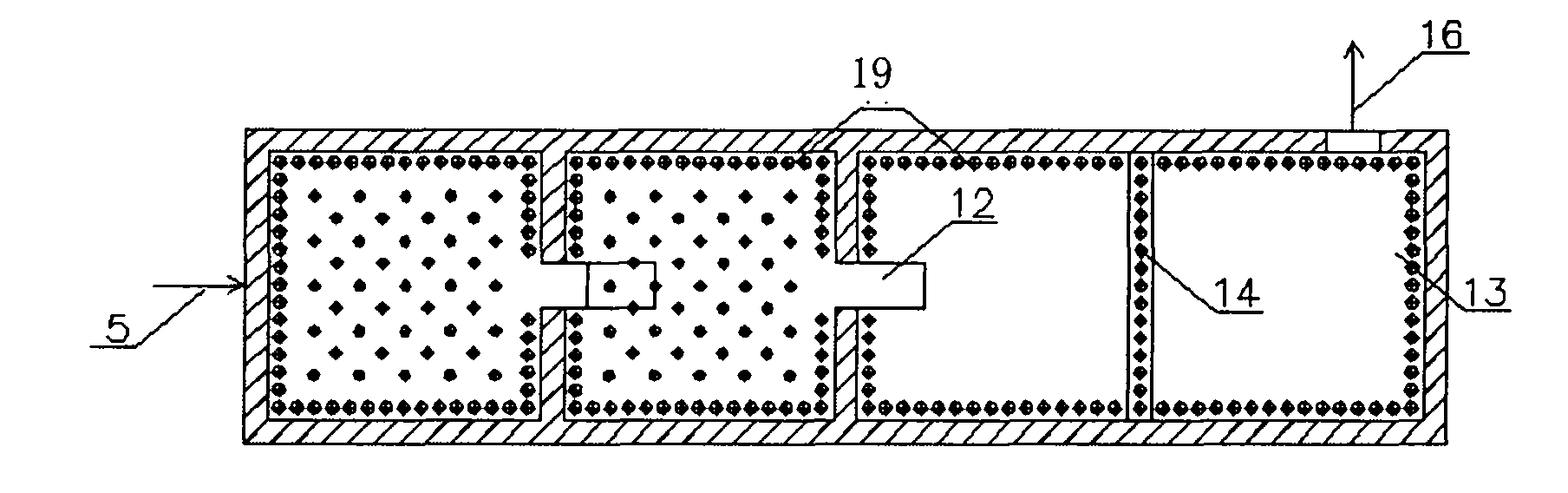

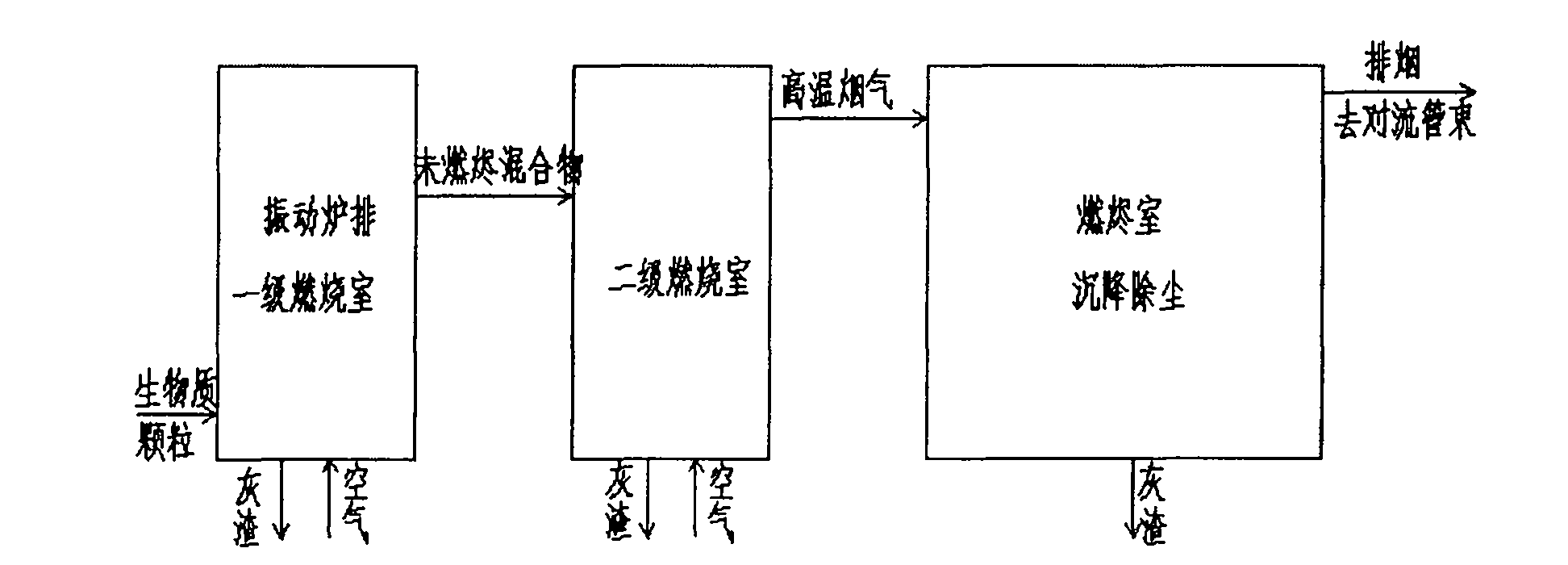

[0012] The main structure of this embodiment includes a primary air chamber 1, a regular ash outlet 2, a vibrating grate 3, a primary combustion chamber 4, a screw feeding inlet 5, a top cap cavity 6, a flue gas guide pipe 7, and a secondary air chamber 8. Periodic ash outlet pipe 9, air distribution plate 10, secondary combustion chamber 11, internal components 12, ember chamber 13, settlement dust removal retaining wall 14, regular ash removal port 15, exit chimney 16, ash accumulation chamber 17, Air supply pipe 18 and water-cooled wall pipe 19; its auxiliary equipment includes convection tube bundle, lower header, upper drum, economizer, blower fan, induced draft fan, circulating water pump, chimney, control and display platform, etc.; its primary combustion chamber 4. The secondary combustion chamber 11 and the ember chamber 13 are sequentially arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com