Electromagnetic folding brake for tractor

A technology of traction machines and brakes, which is applied in the direction of hoisting devices, etc., can solve the problems of unsatisfactory spring safety factor, increased cost, and difficult processing, etc., to meet the needs of market competition, low manufacturing and installation costs, and simple processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

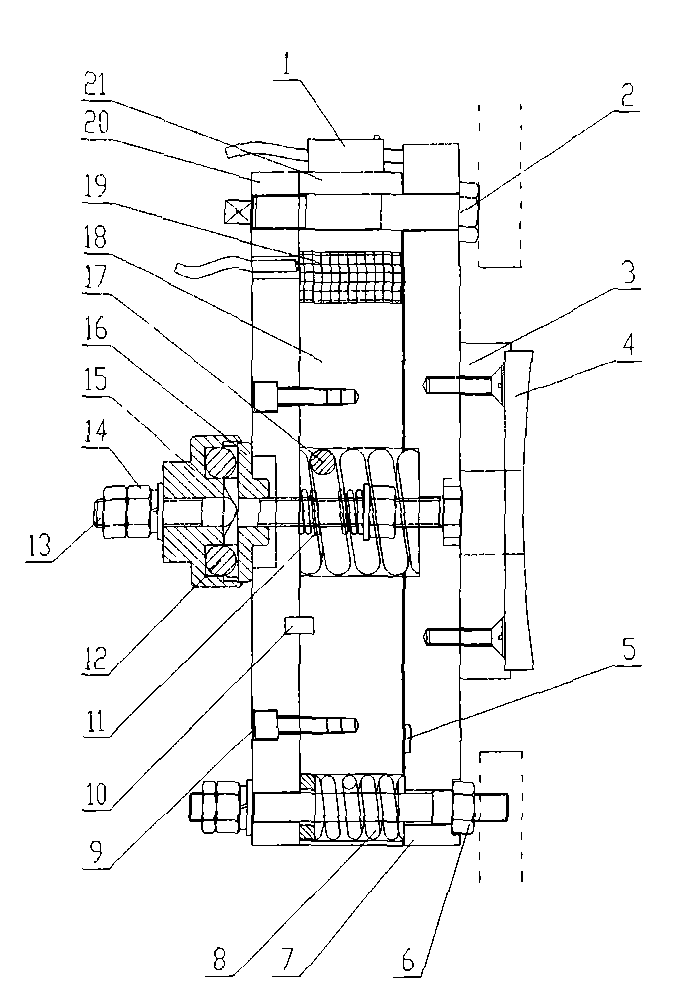

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

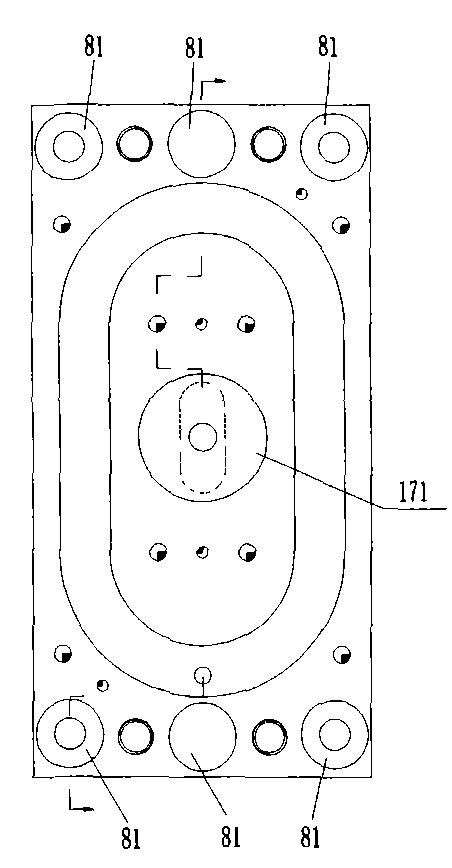

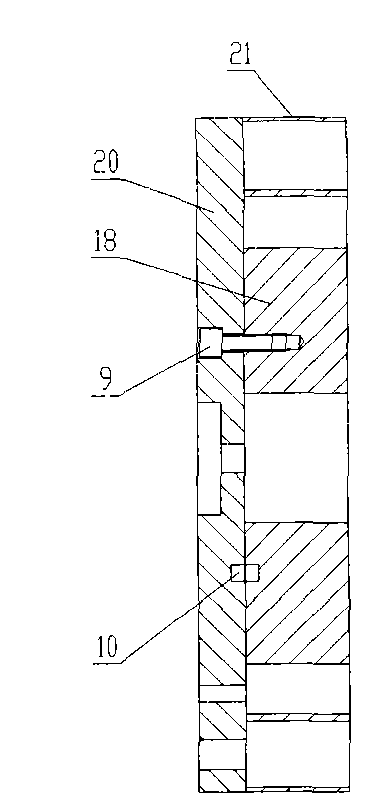

[0020] Such as Figure 1-3 As shown, the electromagnetic stack brake for the traction machine includes a magnetic top plate 7, an iron core assembly, an adjustment bolt 2, a stud bolt 6, a brake spring 8, a brake spring 17, an electromagnetic coil 19, a brake pad 4, a micro-movement A switch 1 and a manual brake release device, wherein: the iron core assembly includes an iron core bottom plate 20 , an iron core inner ring 18 , and an iron core outer ring 21 . An electromagnetic stack brake is installed on the upper part of the left and right sides of the elevator traction machine. When one of the brakes fails, the other can still brake the main engine of the elevator to ensure the safe operation of the elevator.

[0021] The magnetic top plate 7 and the iron core bottom plate 20 are arranged in parallel, and there is a space between the inner surfaces of the two. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com