Culture pond applied to chip packaging

A technology of chip packaging and culture pools, which is applied to tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc., can solve problems such as the inability to ensure smooth cut surfaces, unstable liquid surfaces, and liquid leakage, and achieve effective Conducive to long-term cell culture, simple steps, and reduced volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

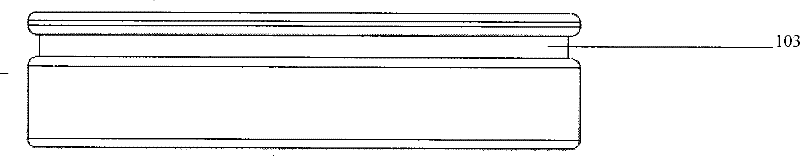

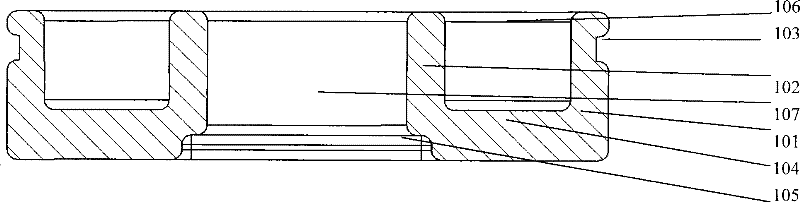

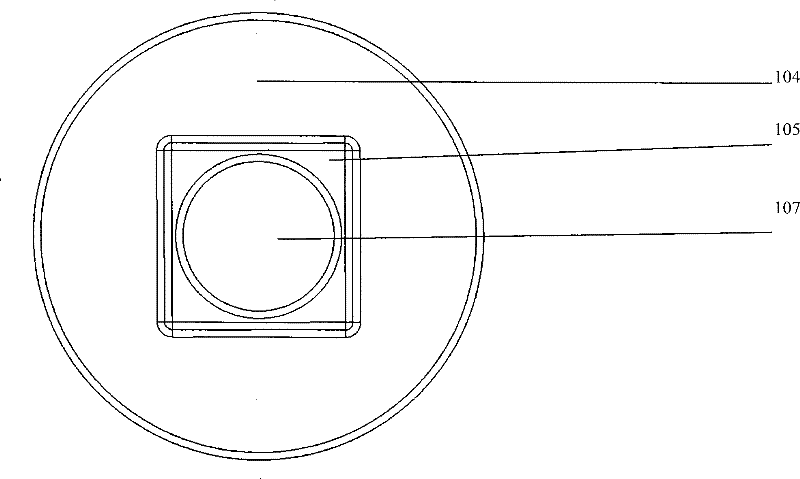

[0021] Example 1: A culture tank for chip packaging with grooves on the wall of the outer ring cavity and a square frame groove at the bottom

[0022] like figure 1 , 2 , 3 and 4, the culture pool is composed of two cavities, large and small, and the small cavity is located in the large cavity, which are respectively the outer ring cavity 106 and the inner ring cavity 107, and the outer ring cavity 106 has There is a bottom 104, the bottom 104 is connected with the inner ring cavity wall 102, the inner ring cavity 107 is a bottomless through cavity, the outer ring cavity wall 101 is provided with a groove 103 parallel to the bottom surface, and the bottom of the culture tank is provided with There is a square groove 105 matching the size of the chip, and the culture pool is made of polystyrene (polystyrene, PS) by integral injection molding.

[0023] In practical applications, the chip can be embedded in the square slot 105, and the outer ring cavity 106 is used to inject st...

Embodiment 2

[0024] Embodiment 2, the culture tank with anti-bacteria cover

[0025] The outer ring cavity wall of the culture pool may not be provided with grooves, with such Figure 5 , 6 , 7, 8 shown in the anti-bacteria cover, other structures are the same as the culture tank of embodiment 1.

[0026] The inner bottom surface of the bacteria-proof cover is provided with pads 108, which are used to raise the bacteria-proof cover by a certain distance, so as to ensure the sterility in the culture tank while CO2 can freely enter and exit.

[0027] The anti-bacteria cover is also made of polystyrene (polystyrene, PS) by integral injection molding.

Embodiment 3

[0028] Example 3: Encapsulation of Cell Chips in Culture Pools

[0029] First, the chip unit is glued to the center of the printed circuit board; secondly, the gold wire ball welding is carried out, and the pad of the chip unit is connected to the pad of the printed circuit board by welding; then, the gold wire of the bonding is protected with silica gel; finally, the culture pool is Stick to the printed circuit board, and embed the chip unit in the bottom square groove 105 of the culture tank, so that the bottom surface 104 and the printed circuit board have as large a contact area as possible, thereby ensuring firm bonding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com