Production technology for brazing diamond polycrystal and used mold thereof

A production process, diamond technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of high production cost, inability to meet the needs of diamond tools, low output, etc., and achieve low production cost, high compactness, The effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

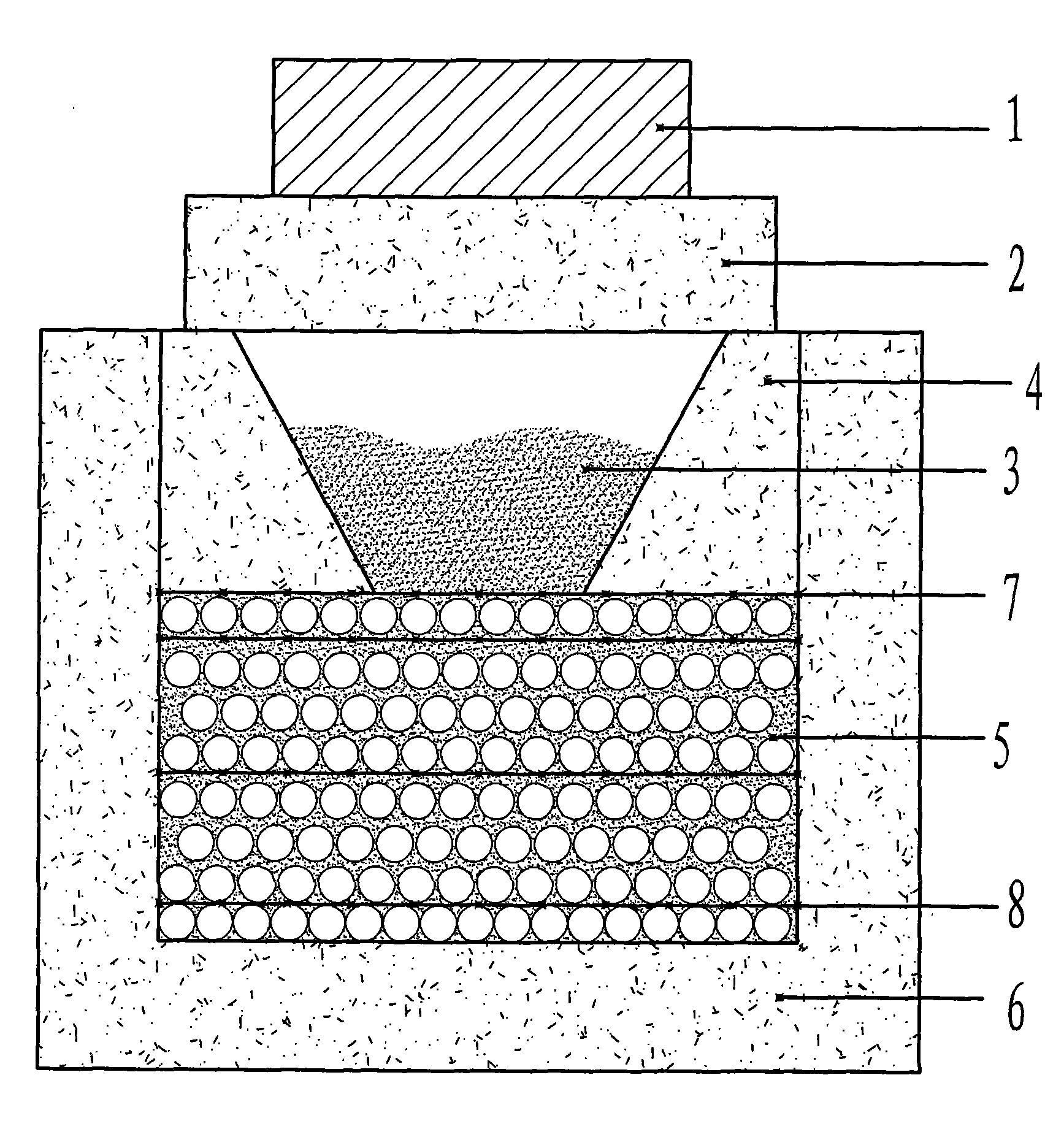

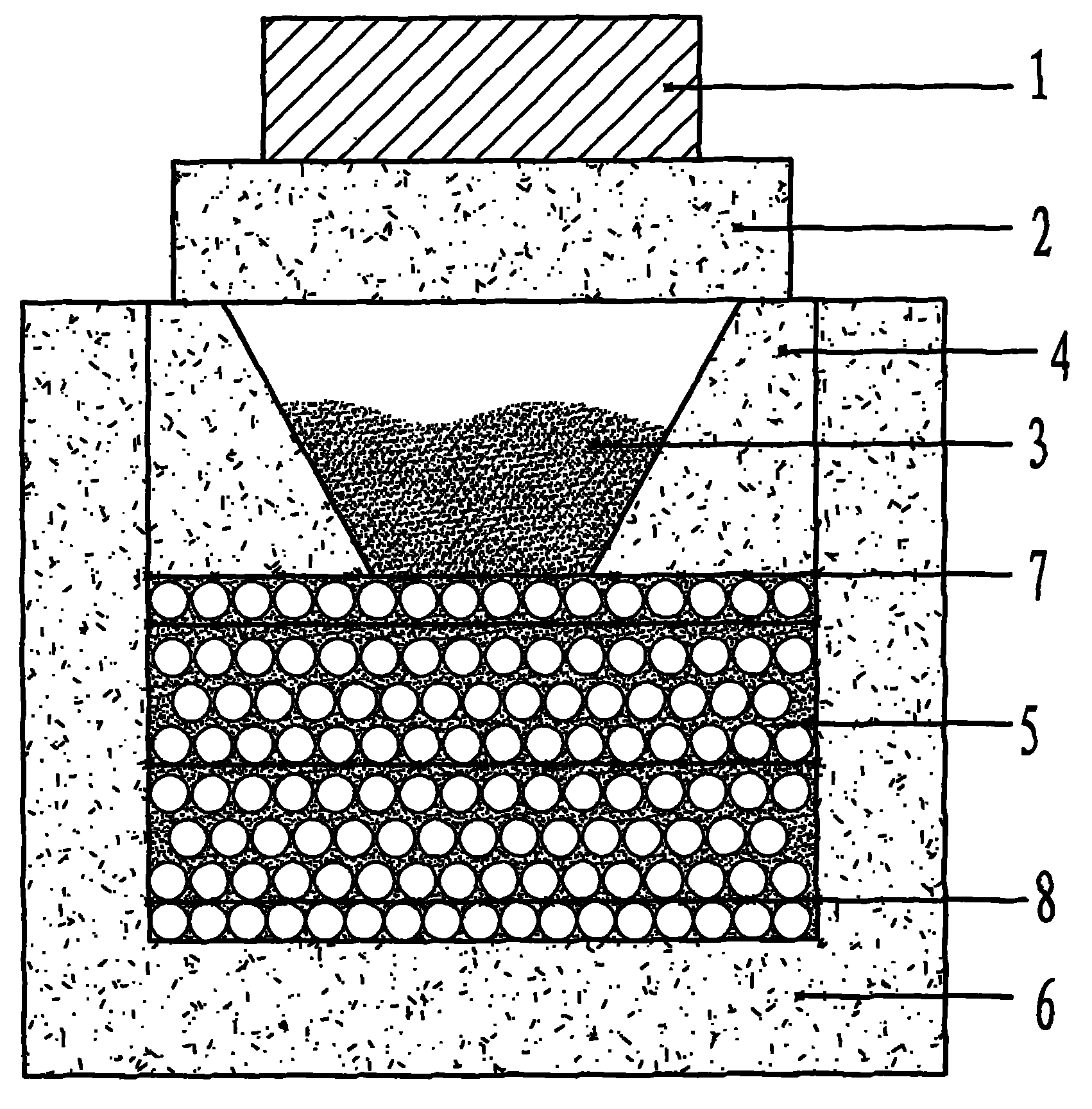

[0016] The structure disclosed in the above accompanying drawings is the structure of an embodiment of the mold used in the present invention.

[0017] The parts and their labels in the figure are: 1. Iron block, 2. Graphite or ceramic block, 3. Brazing powder, 4. Feed graphite ring or ceramic ring, 5. The mixture of brazing powder and diamond particles, 6. Cylindrical graphite or ceramic mold body, 7. Process metal mesh, 8. Reinforced metal mesh or wire.

[0018] Below in conjunction with accompanying drawing and embodiment the invention is further introduced:

[0019] The brazing powder and diamond particles are uniformly mixed at an optimal mass ratio of 2.23:1, and a cavity is processed on the high-purity cylindrical graphite mold body 6 according to the designed shape. The matching gap between the cavity and the filler graphite ring 4 is (0.02-0.03) mm, and an anti-seepage release agent (such as cubic boron nitride) is coated on the inner wall of the cavity, assembled ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com