Patents

Literature

41results about How to "High volume concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

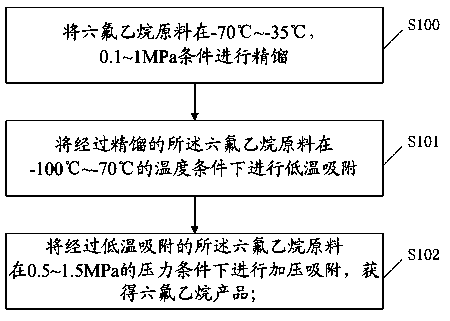

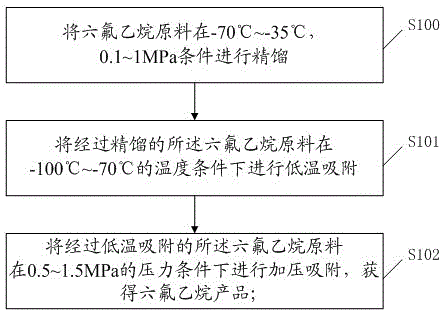

Hexafluoroethane purification method

ActiveCN103664501AHigh puritySolve storage problemsHalogenated hydrocarbon separation/purificationHexafluoroethanePurification methods

The invention discloses a hexafluoroethane purification method which comprises the following steps: rectifying a hexafluoroethane raw material under the conditions of (-70)-(-35) DEG C and 0.1-1 MPa; performing low-temperature adsorption on the rectified hexafluoroethane raw material under the temperature conditions of (-100)-(-70) DEG C; and performing pressurized adsorption on the hexafluoroethane raw material after low-temperature adsorption under the pressure conditions of 0.5-1.5 MPa, thus obtaining the hexafluoroethane product, wherein the CO2 volume concentration of the hexafluoroethane product is no more than 0.5 ppm, and the H2O volume concentration is no more than 1 ppm. According to the invention, the problem that potential safety hazard is caused due to insufficient CO2 and H2O removal depth and introduction of anhydrous HCl in hexafluoroethane is solved, the energy consumption is reduced, and the adsorption effect of adsorbent is enhanced; and the purity of the hexafluoroethane product is up to 99.9995% or above, thus meeting the requirements for electronic specific gas in the semiconductor and micro-electronics industry.

Owner:FOSHAN HUATE GASES +1

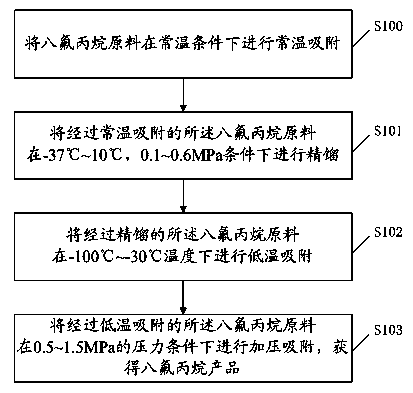

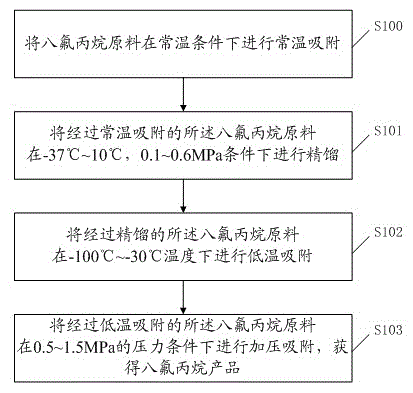

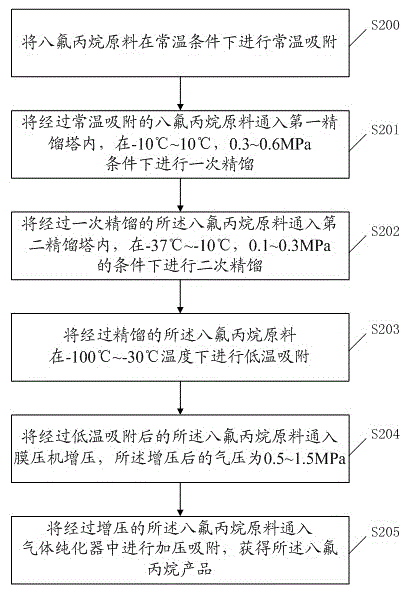

Octafluoropropane purifying method

ActiveCN103664502AHigh purityAvoid high energy consumptionHalogenated hydrocarbon separation/purificationChemistryCarbon dioxide

The invention discloses an octafluoropropane purifying method. The octafluoropropane purifying method comprises the following steps: carrying out normal-temperature adsorption on an octafluoropropane material under a normal-temperature condition; carrying out distillation on the octafluoropropane material adsorbed at the normal temperature under conditions with the temperature of -37 DEG C-10 DEG C and pressure of 0.1 MPa-0.6 MPa; carrying out low-temperature adsorption on the distilled octafluoropropane material at the temperature ranging from-100 DEG C to -30 DEG C; carrying out pressurized adsorption on the low-temperature adsorbed octafluoropropane material under the pressure condition of 0.5 MPa-1.5 MPa to obtain an octafluoropropane product. The octafluoropropane purifying method disclosed by the invention is adopted, so that not only most of fluorine-chlorine-carbon compound-containing impurities are removed, but also a problem that removing depth for carbon dioxide and carbon in the prior art is not enough is solved, thus energy consumption is lowered, adsorption effect of an adsorbent is strengthened and the purity of the octafluoropropane product is over 99.999%.

Owner:FOSHAN HUATE GASES +1

One-component salt fog resistant water paint and preparation method thereof

ActiveCN104893489AHigh volume concentrationEvenly arrangedAnti-corrosive paintsPolyurea/polyurethane coatingsMetallurgyPhysical chemistry

The invention discloses one-component salt fog resistant water paint and a preparation method thereof. The water paint includes the following raw materials in parts by weight: 20-46 parts of EPMC, 5-18 parts of special EPMC, 20-40 parts of anti-rust pigment, 13-30 parts of deionized water, 2-10 parts of an environment-friendly additive. The product is excellent in performance: the hardness is greater than or equal to H, the adhesive force is of 0-1 level, and the salt fog resistant duration is longer than 800 hours; the paint is environment-friendly and wide in application range.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

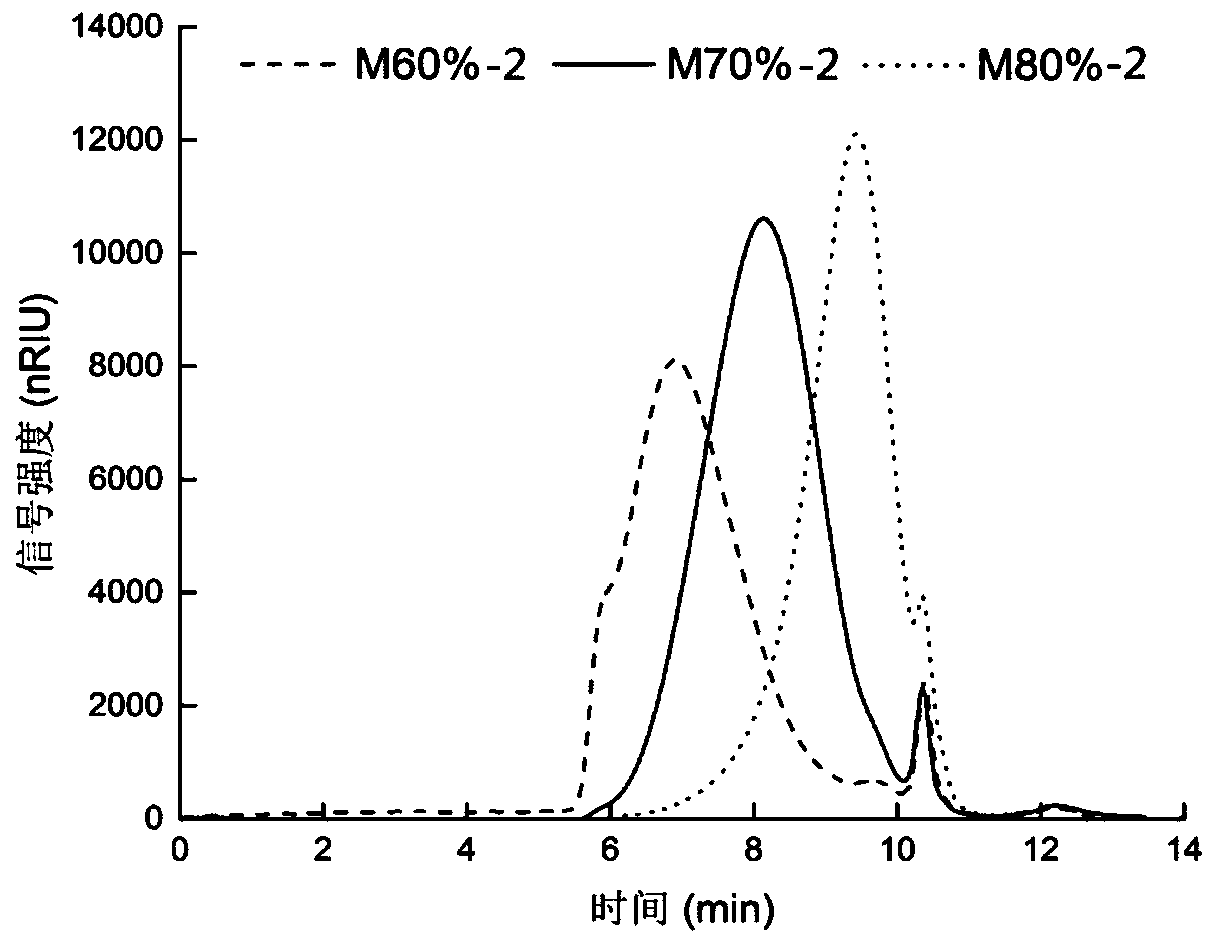

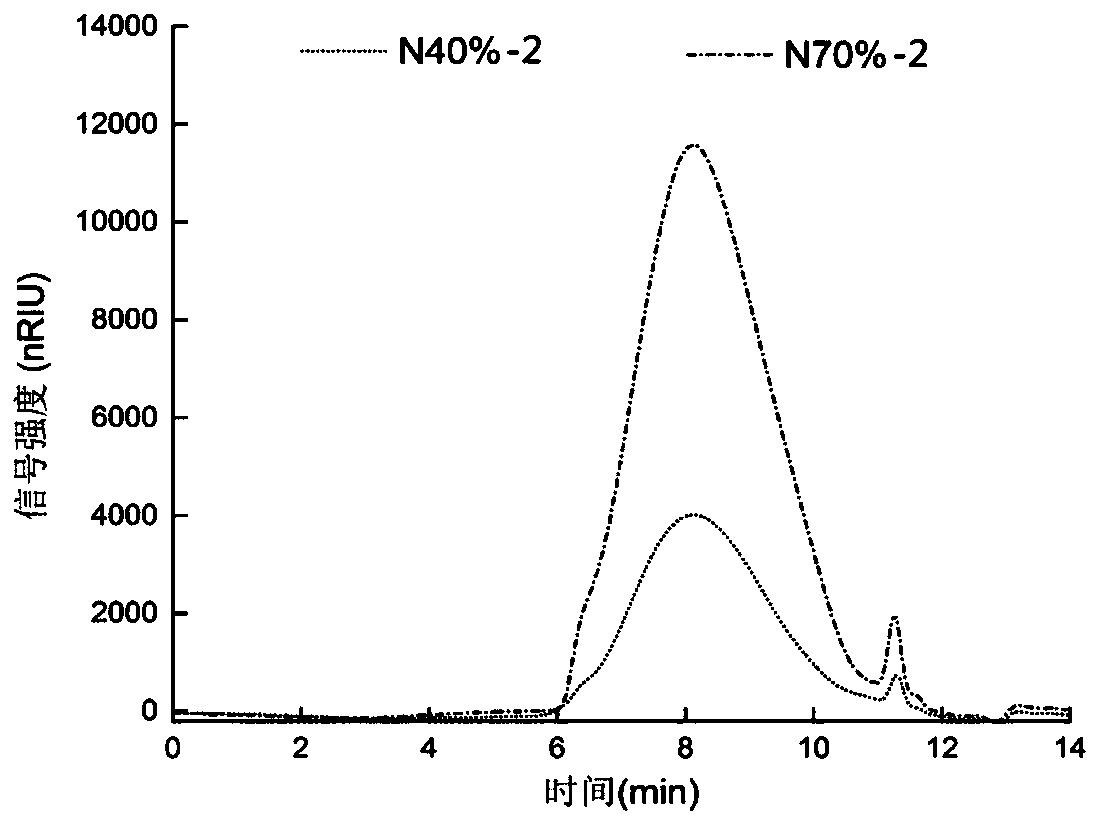

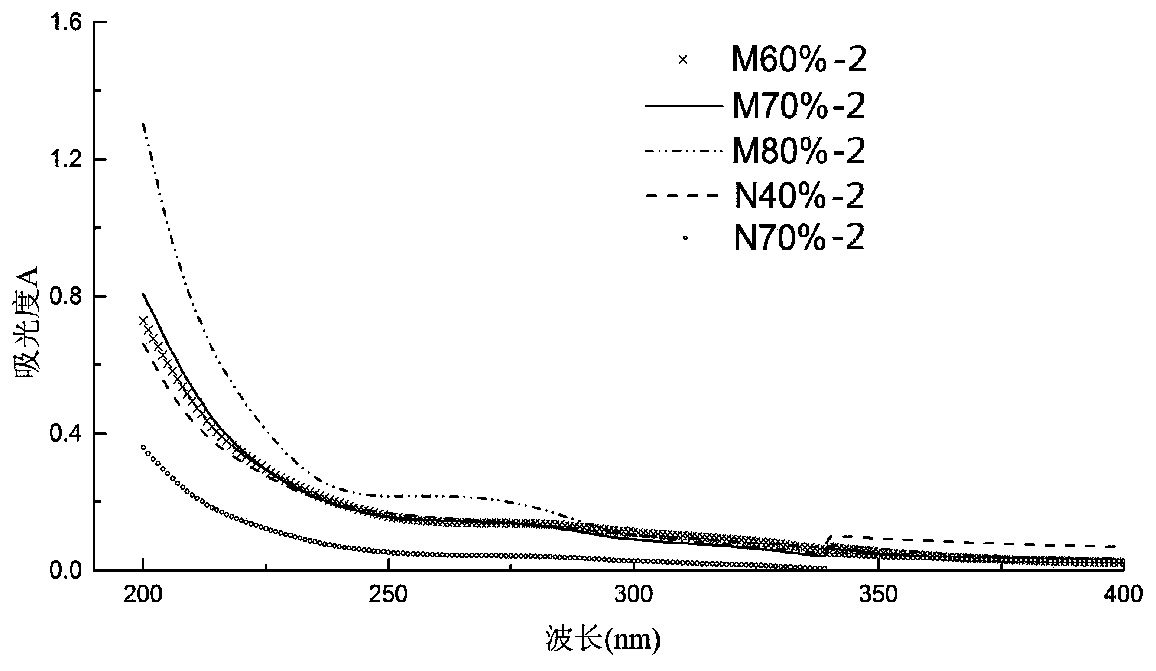

Preparation method of araboxylan and product

The invention discloses a preparation method of araboxylan. The preparation method specifically comprises the following steps: (1) removing starch from wheat bran; (2) obtaining a polysaccharide solution by adopting an alkali extraction method; (3) carrying out deproteinization treatment on the polysaccharide solution; (4) carrying out enzyme treatment and dialysis on the deproteinized polysaccharide solution; (5) carrying out enzymolysis on the dialyzed polysaccharide solution; (6) respectively carrying out alcohol precipitation classification on the polysaccharide solution which is not subjected to enzymolysis and the polysaccharide solution which is subjected to enzymolysis to obtain araboxylan with different molecular weights; and (7) carrying out secondary enzyme treatment and secondary dialysis on araboxylan with different molecular weights. The preparation method is simple and feasible, the utilization rate of the raw material wheat bran can be increased, araboxylan with different fractions can be obtained, the structures are different, the functional effects of reducing blood sugar, resisting oxidation and the like to different extents are achieved, and the medical value ishigh.

Owner:HUAZHONG AGRI UNIV

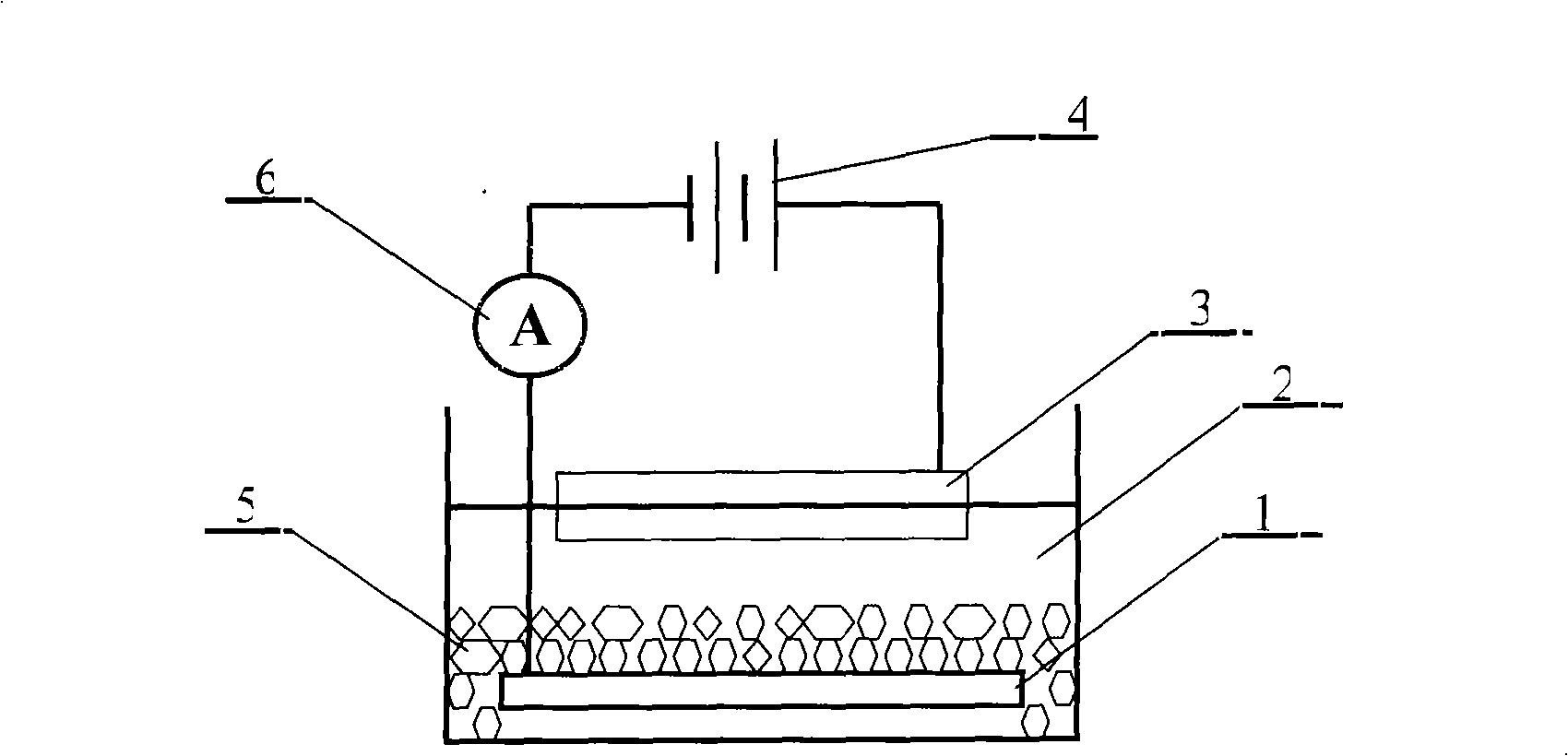

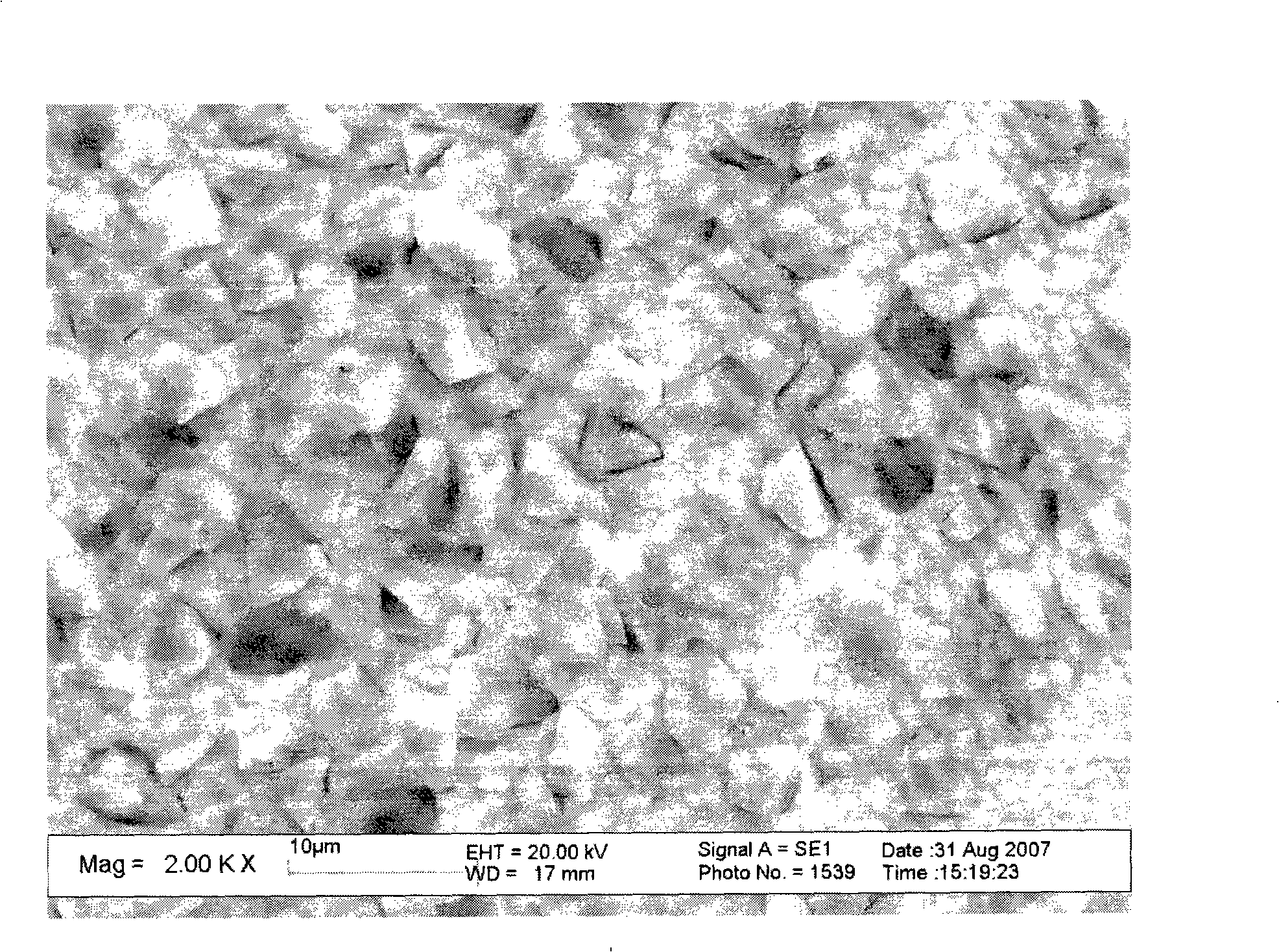

Chromium/diamond composite deposite and preparation method thereof

InactiveCN101255592AHigh volume concentrationEvenly dispersedElectrolytic coatingsGraphiteVolume concentration

The invention provides a chromium / diamond composite clad layer, the preparation method comprising the steps of: depositing a layer of chromium on surface of a work-piece by electroplating, and then depositing a layer of chromium / diamond composite clad layer, finally depositing a chromium back-up coat. The chromium / diamond composite clad layer produced by the method has 1 to 1.5um of chrome plating thickness of the under-plate; the total chrome plating thickness of the sad-feeding plate and the back-up plate is 80% to 90% of the diamond grains; the chromium / diamond composite clad layer has high volume concentration, which is dispersed evenly without crack on the surface, so as to prevent graphite catalytic element in the work-piece, such as Fe, Ni, Co, etc spreading to diamond interface; the chromium / diamond composite clad layer can be adopted as clad layer of CVD diamond; the deposited CVD diamond film is provided with mosaic structured interface, so as to greatly improve CVD diamond film / foundation interface bonding force.

Owner:SOUTH CHINA UNIV OF TECH

Sacrificial water corrosion-resistant epoxy paint composition

InactiveCN1451701ANo pollutionLow costAnti-corrosive paintsEpoxy resin coatingsEpoxyWater dispersible

A sacrificial anticorrosion water epoxy paint composition contains water-dispersive basic epoxy resin, multi-metal alloy powder, water-soluble solidifying agent prepared from polyamine and polyol, and rheologic nano assistant. Its advantages are high stability, excellent anticorrosion and mechanical performance of its film, and no release of harmful gas.

Owner:杨瑞影

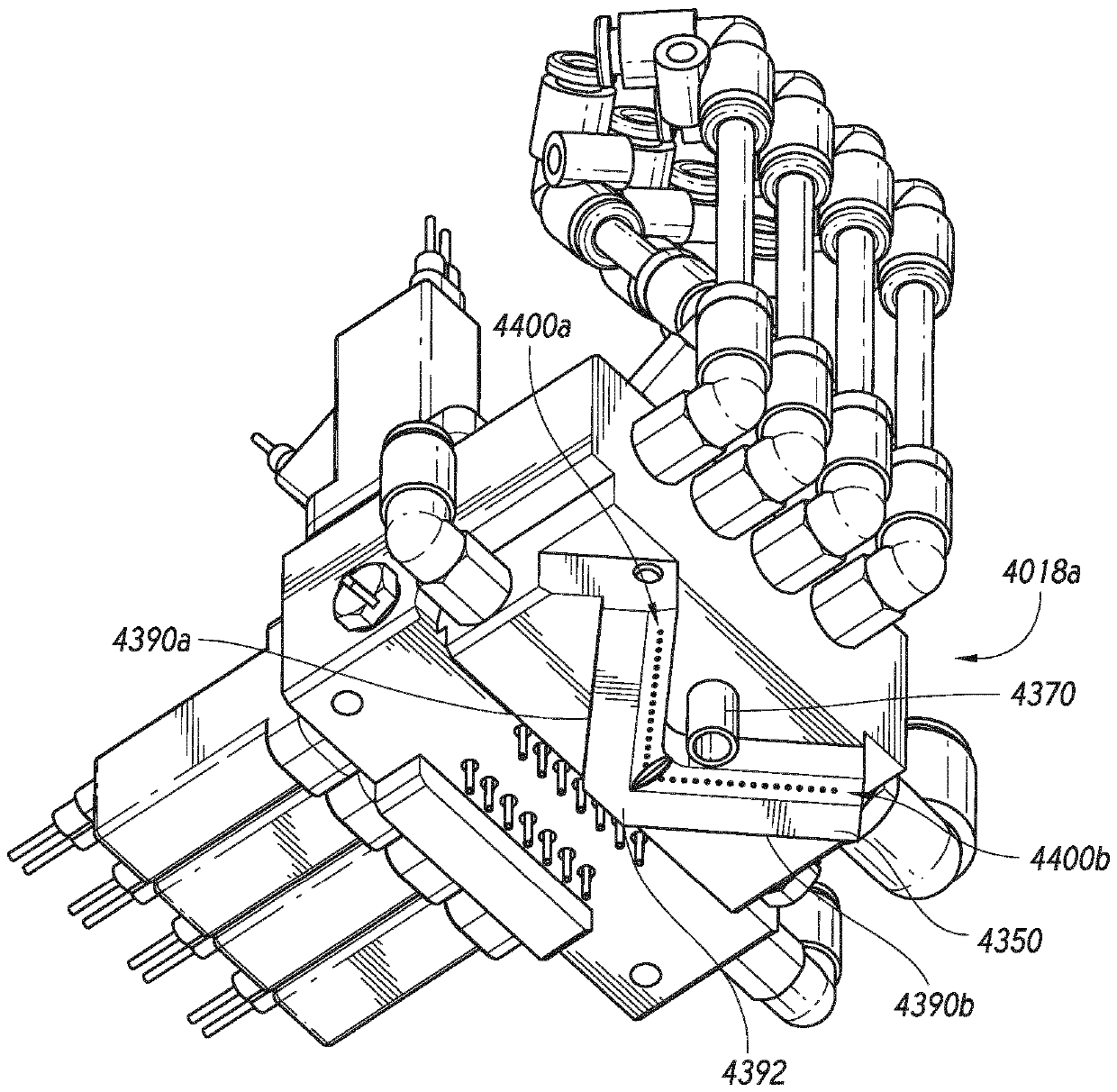

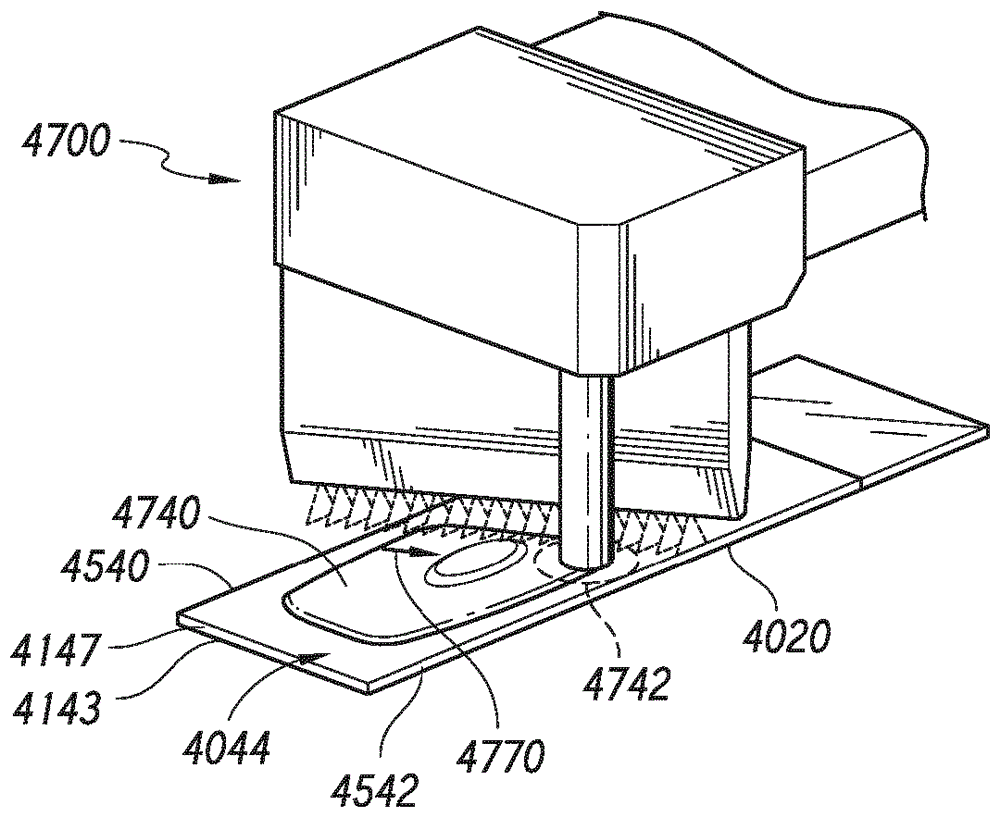

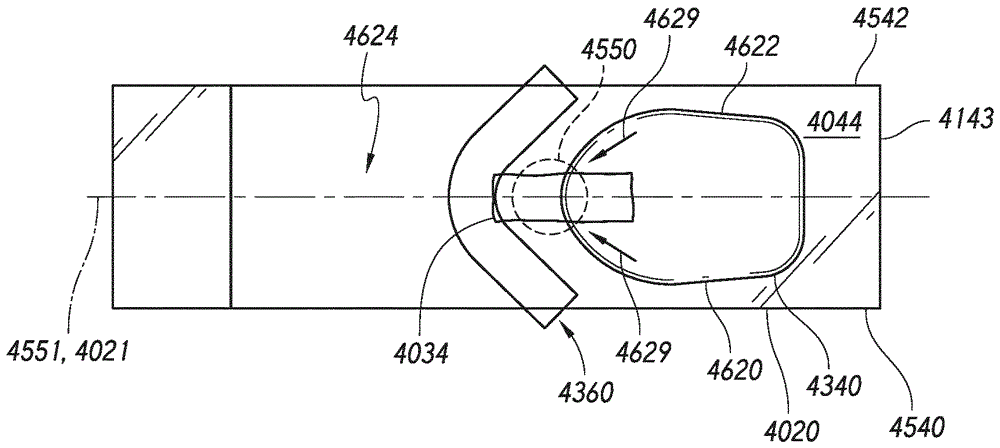

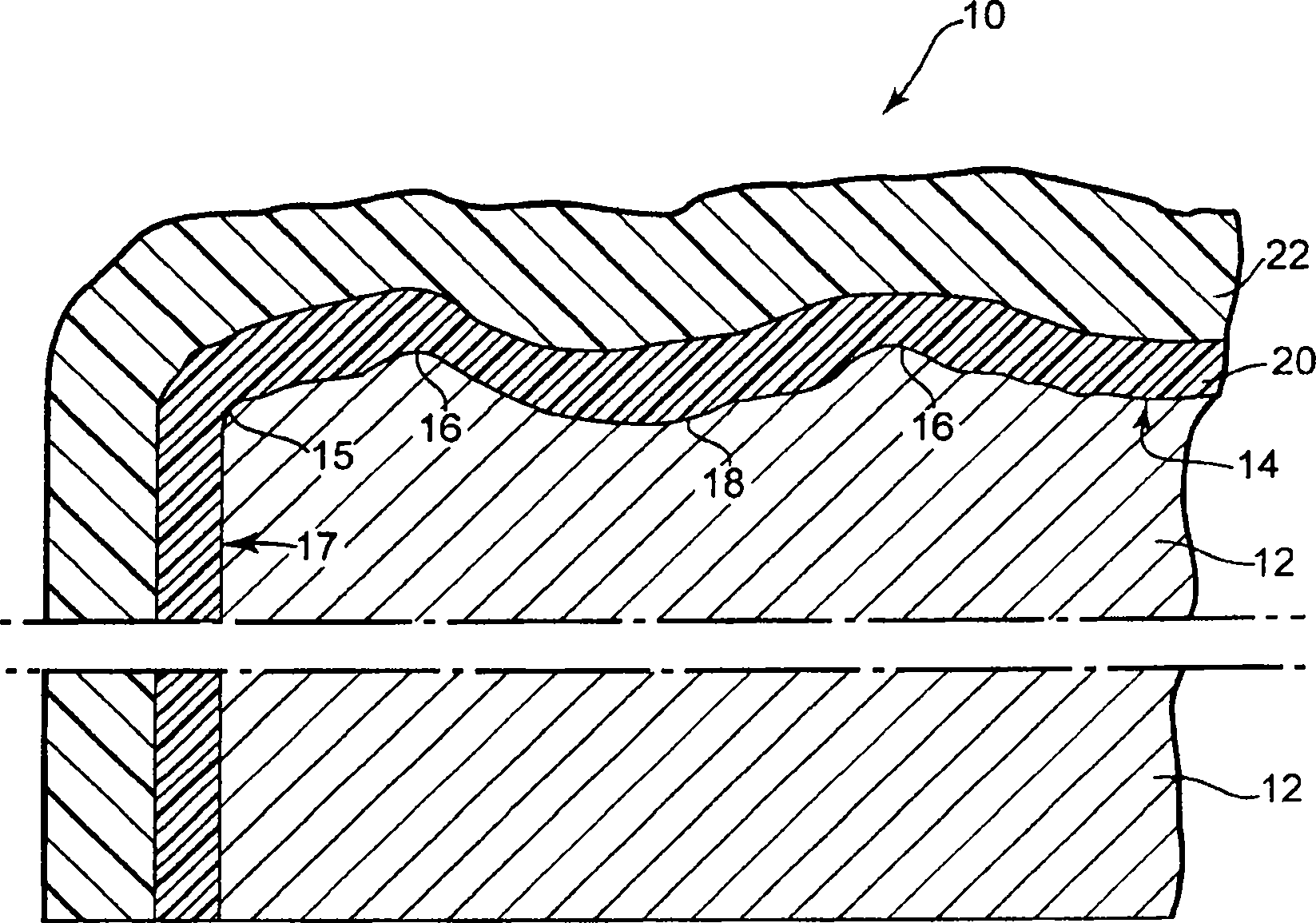

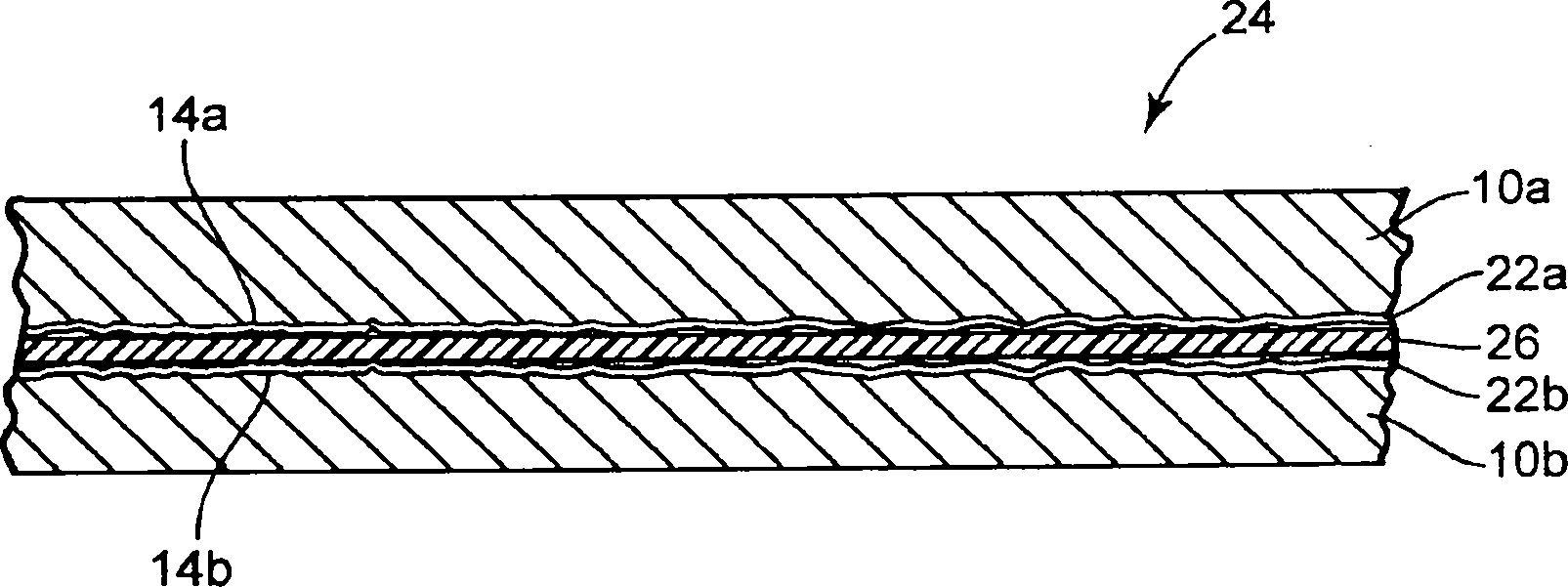

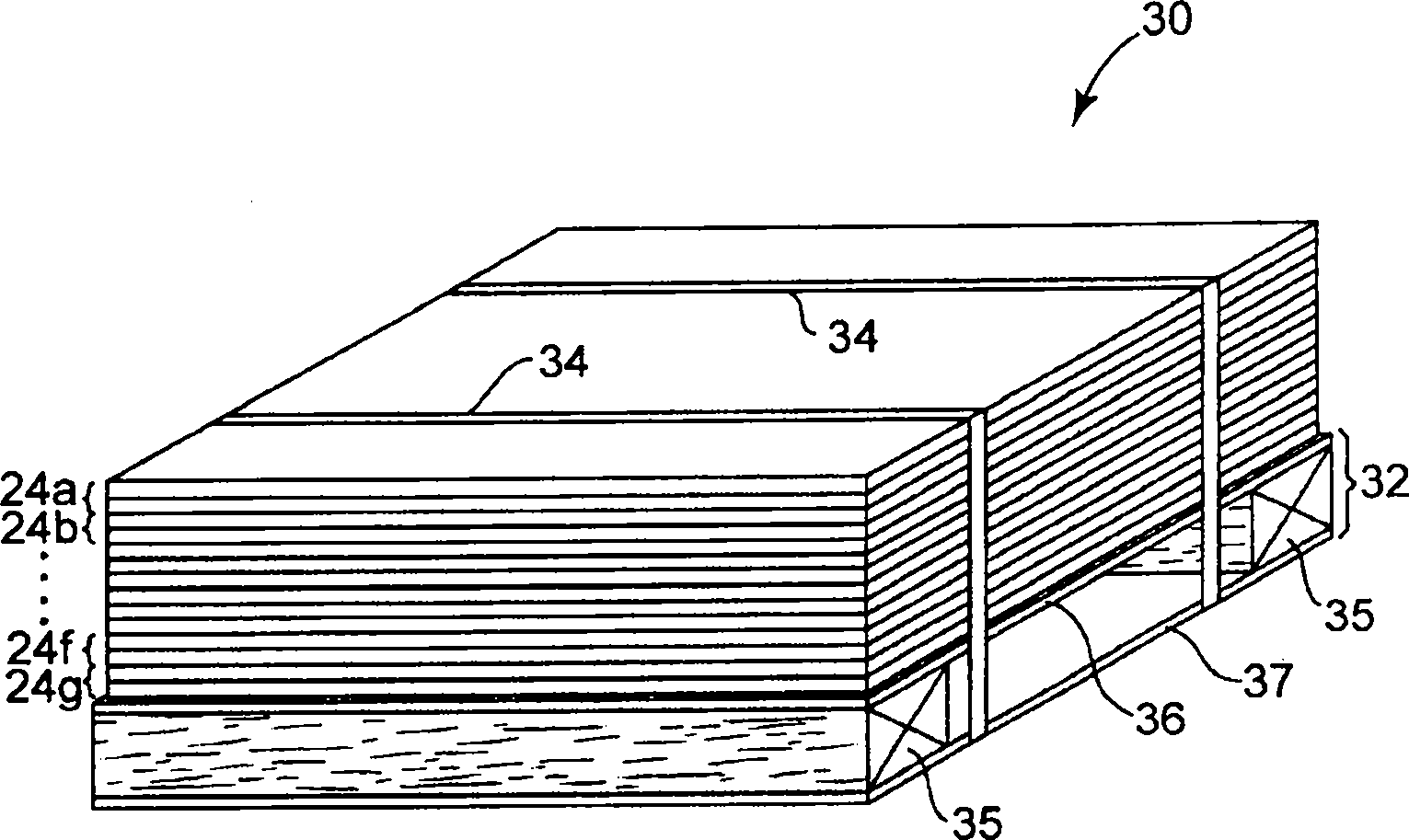

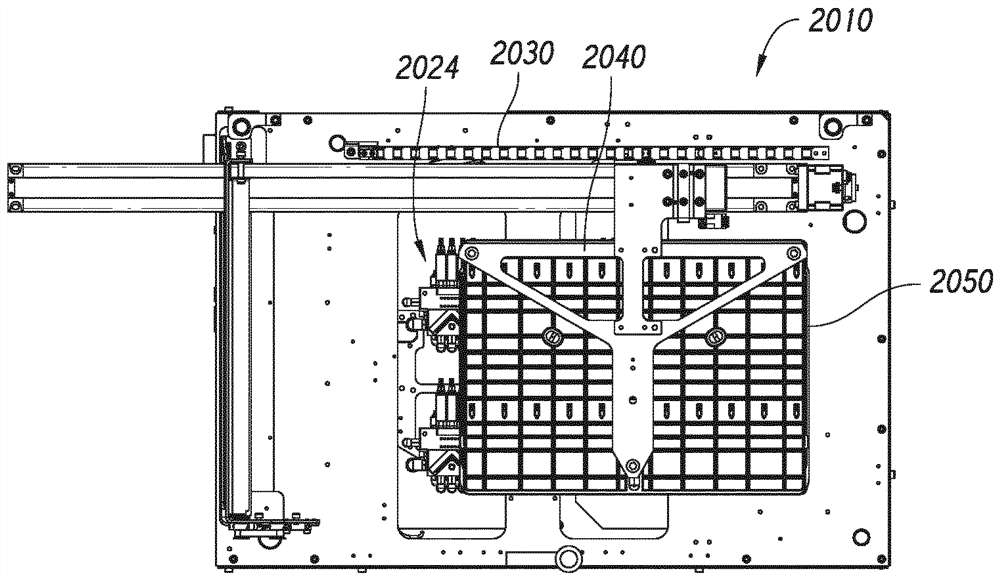

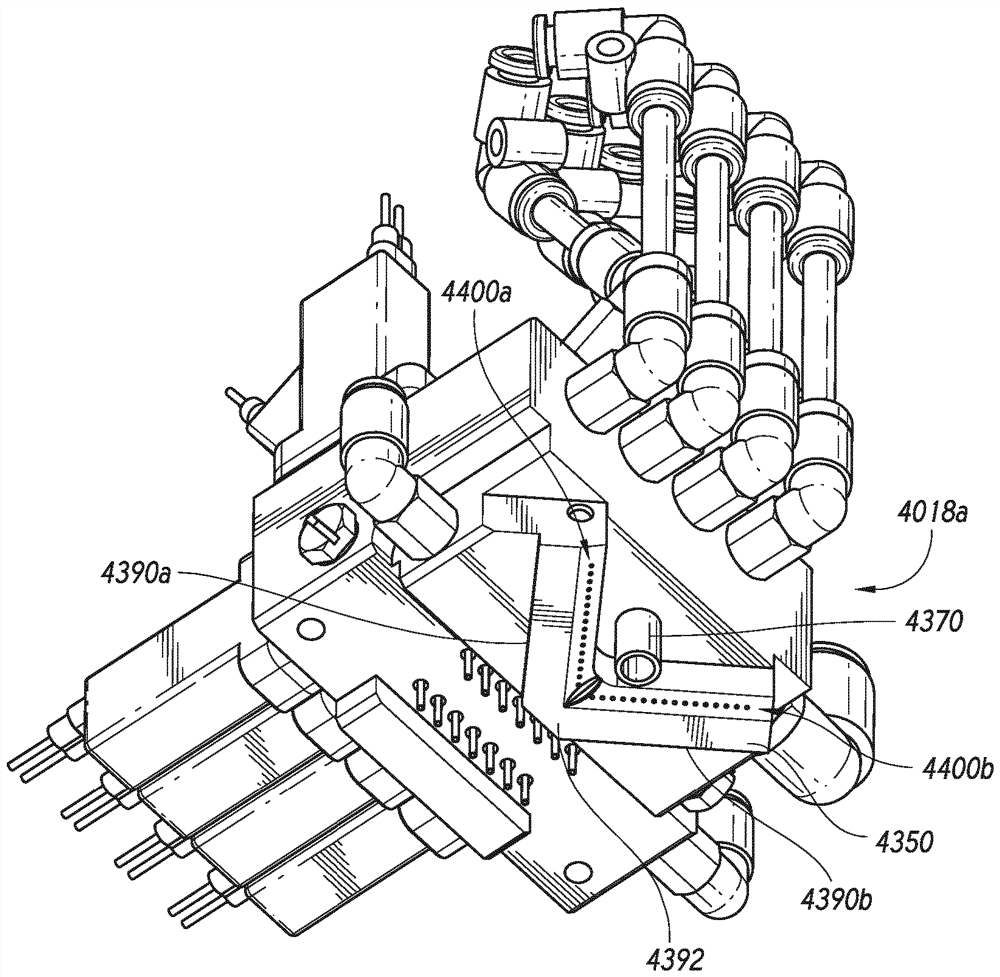

Staining reagents and other liquids for histological processing of biological specimens and associated technology

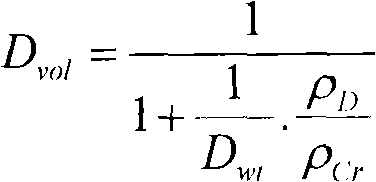

Processing specimens in an automated histological staining system comprising robotically moving a slide carrier into a stainer of the system, the slide carrier carrying slides which respectively carry the specimens, and the specimens being at least partially embedded in paraffin. Liquids are automatically dispensed onto the slides according to a predetermined recipe for at least deparaffinizing, staining, and counterstaining the specimens. The slide carrier can be robotically moved out of the stainer after automatically dispensing the liquids. In some embodiments, a total of all liquid dispensed onto the slides after moving the slide carrier into the stainer and before moving the slide carrier out of the stainer has a greater volumetric concentration of polyol than of monohydric alcohol.

Owner:VENTANA MEDICAL SYST INC

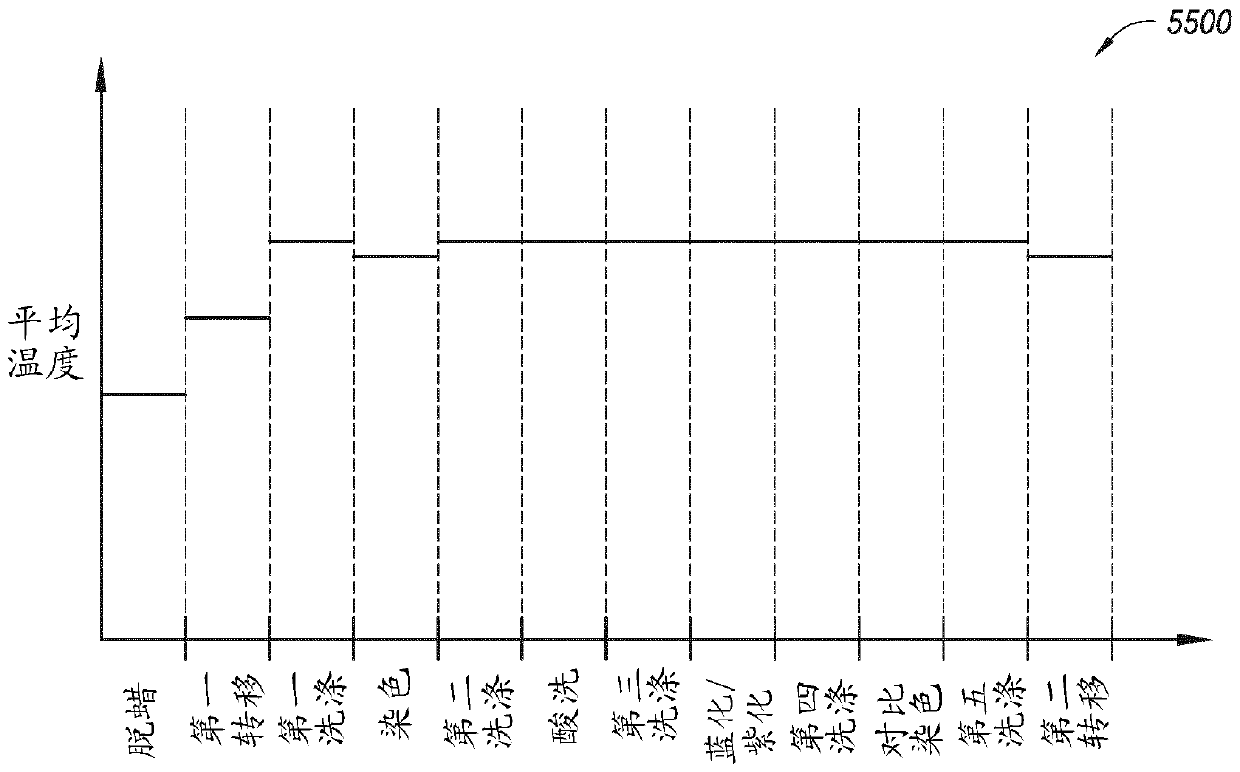

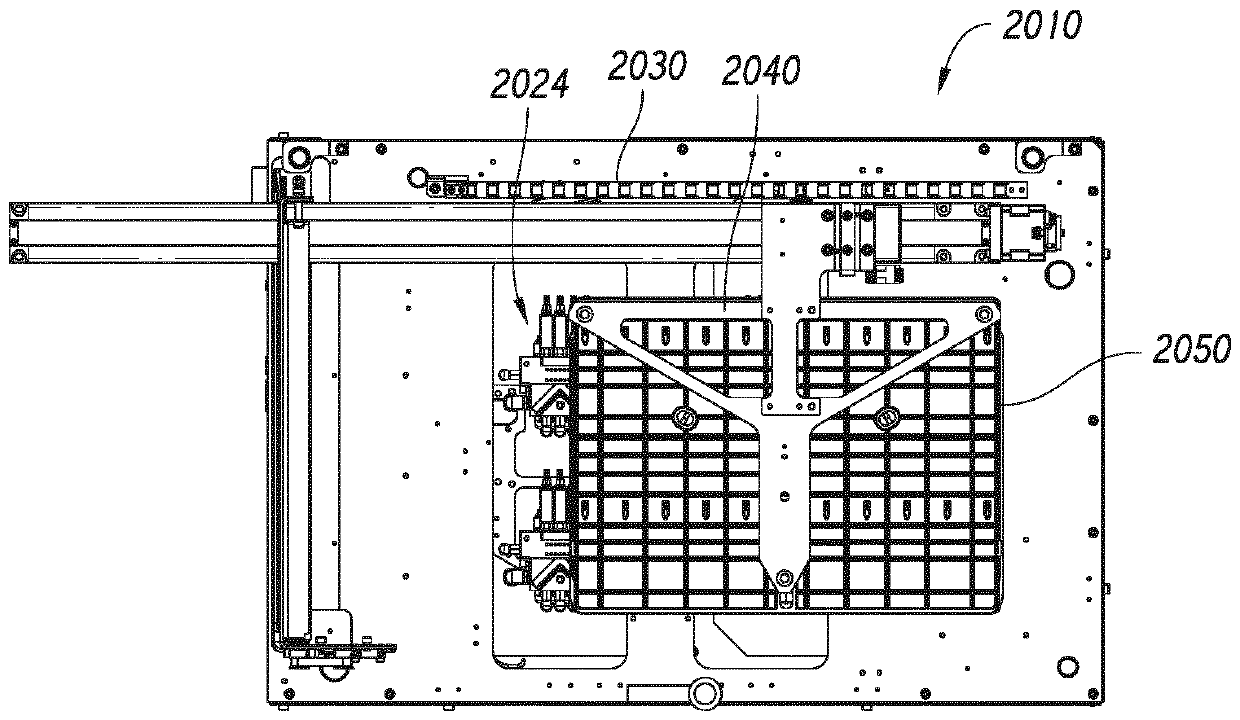

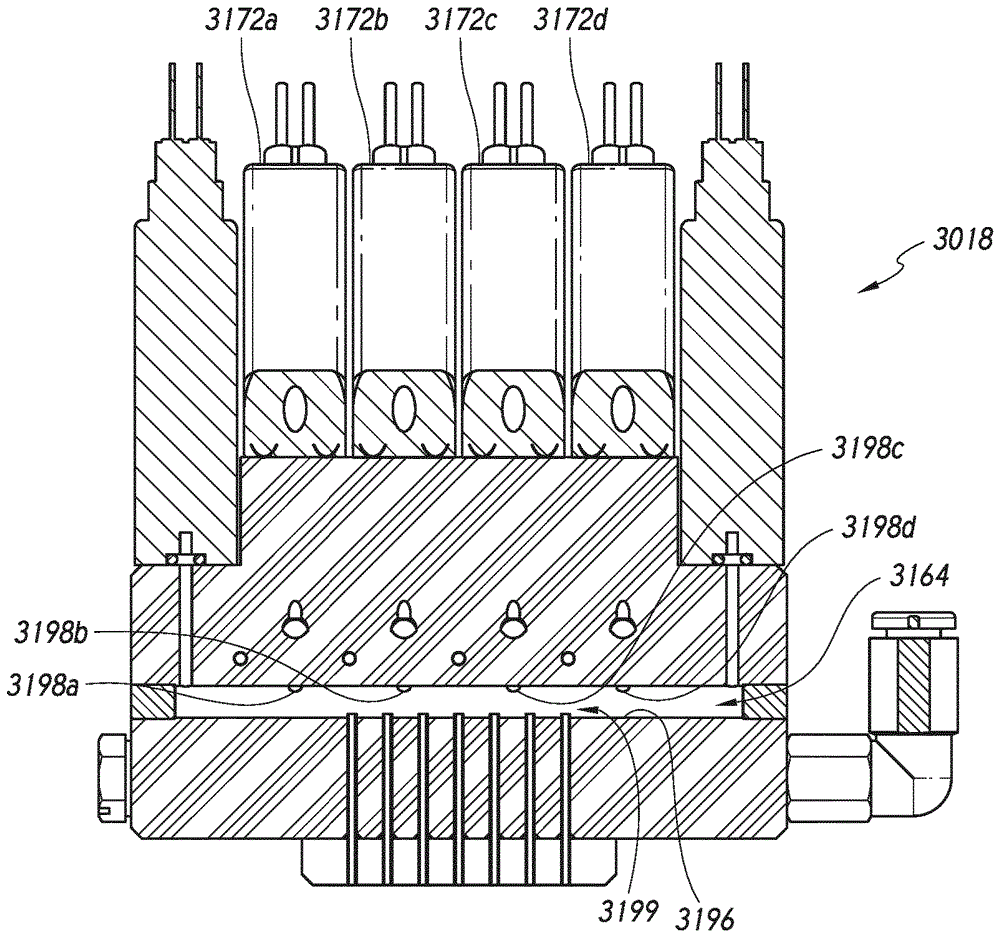

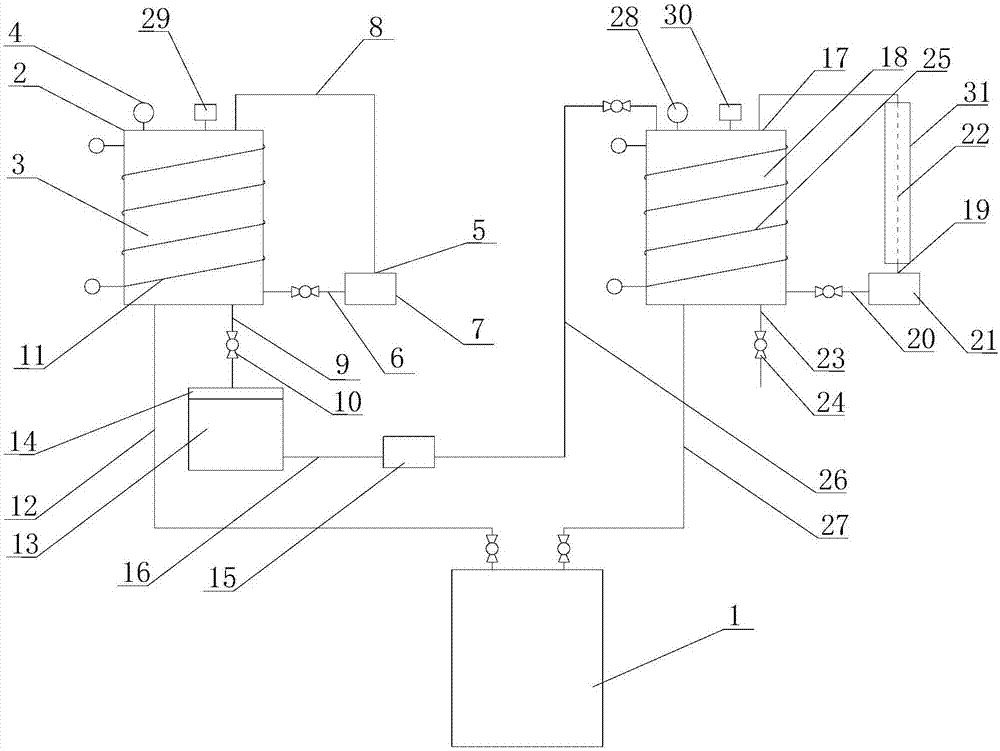

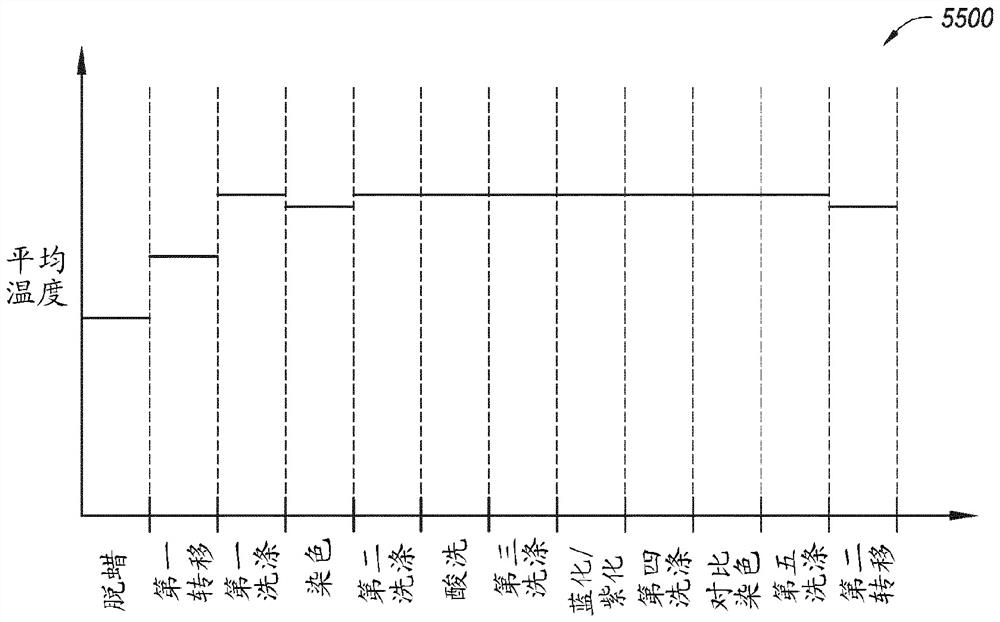

Thermal management in the context of automated histological processing of biological specimens and associated technology

ActiveCN105980827AHigh volume concentrationHeating or cooling apparatusPreparing sample for investigationTemperature controlHistological staining

Methods and system capable of processing specimens carried by slides within an automated histological staining system. A slide carrier is moved toward and into a temperature-controlled internal environment of a stainer within the system. The slide carrier carries a first slide and a second slide, and the first and second slides can carry a first specimen and a second specimen, respectively. The first and second specimens are stained with at least one of a staining reagent and a counterstaining reagent while the first and second slides are within the internal environment and while an average temperature of the internal environment is greater than ambient temperature. The slide carrier can be moved out of the internal environment after staining one or both specimens.

Owner:VENTANA MEDICAL SYST INC

Anti-wear fingerprint-proofing film-coated glass used for touch screen and preparation method thereof

The invention relates to the technical field of touch screens, and especially relates to anti-wear fingerprint-proofing film-coated glass used for a touch screen and a preparation method thereof. The film-coated glass includes a thin glass sheet and a protective film tightly attached thereto. The protective film includes a composite thin film, which is directly attached to the thin glass sheet, and a SiO2 film, which is formed on the composite thin film. The composite thin film contains silver-carrying nano TiO2; the surface of the SiO2 film has an uneven micro-structure; the protective film is formed by uniformly spray-coating the surface of the thin glass sheet with a composite coating liquid to form the composite thin film after solidification and then spray-coating the composite thin film with a SiO2 coating liquid to form the SiO2 film after solidification. The composite coating liquid is prepared with ethanol as a main solvent, wherein the silver-carrying nano TiO2 particles and SiO2 gel are dispersed in the composite coating liquid according to the mass ratio of 1:2. The method is easy and controllable. The film-coated glass is wear-resistant and is durable, has self-cleaning effect, has fingerprint-proofing and anti-reflection effects and is suitable for the technical field of touch screens.

Owner:CHONGQING ZHONGGUANGDIAN DISPLAY TECH CO LTD

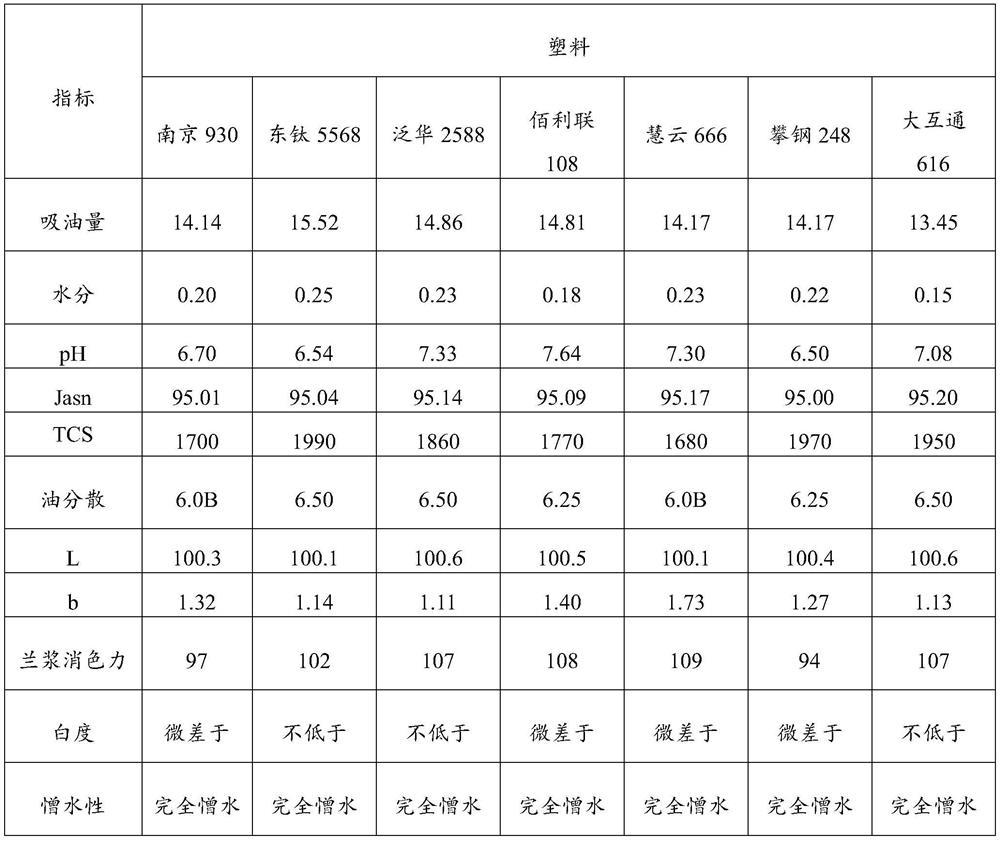

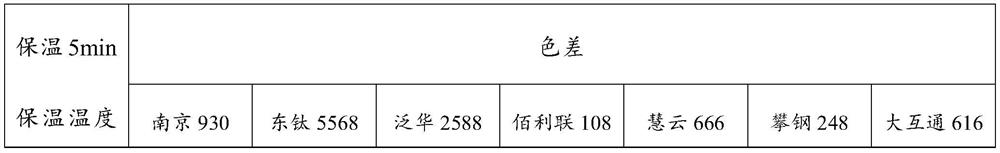

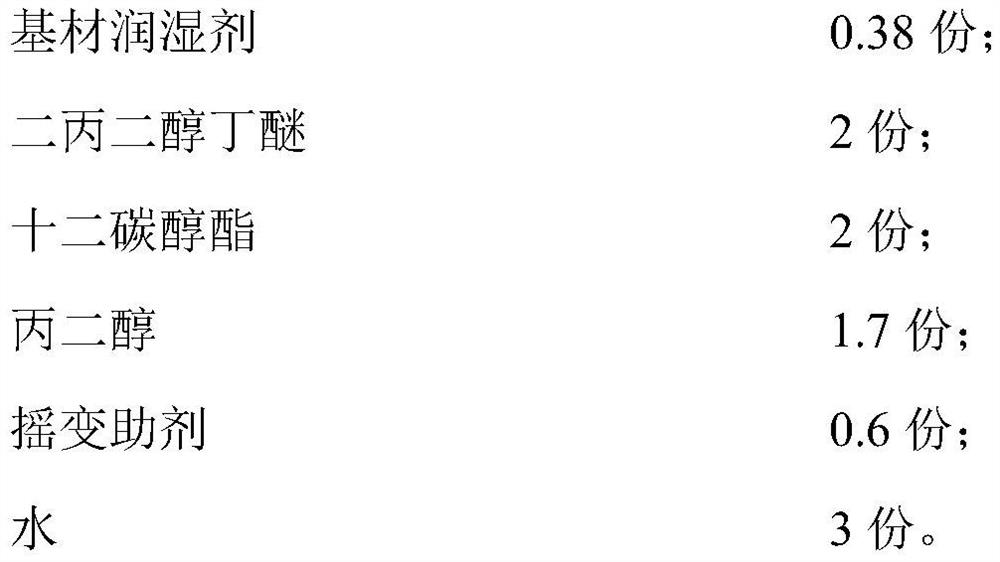

Color masterbatch plastic grade titanium dioxide and preparation method thereof

ActiveCN112646396AAvoid direct contactGood weather resistancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsOrganic filmMasterbatch

The invention provides color masterbatch plastic grade titanium dioxide which comprises an inner core and a coating layer coating the inner core, the inner core is titanium dioxide, and the coating layer comprises a first organic film layer coating the inner core, an inorganic film layer coating the first organic film layer and a second organic film layer coating the inorganic film layer. The preparation method of the titanium dioxide comprises the steps of pulping and dispersing, first organic coating, agent-free coating, filter pressing and second organic coating. According to the preparation method, surface coating and modification are carried out in a slurry state through organic matter before inorganic surface coating, so that the compatibility of titanium dioxide in an application system is greatly improved; in a flash evaporation drying link, amino silicone oil emulsion is adopted for further surface modification, and the compatibility and bonding force between powder particles and resin are enhanced; and a silane coupling agent is added in a steam flow crushing link for further modification, so that titanium dioxide particles are completely hydrophobic and oleophylic.

Owner:攀枝花大互通钛业有限公司

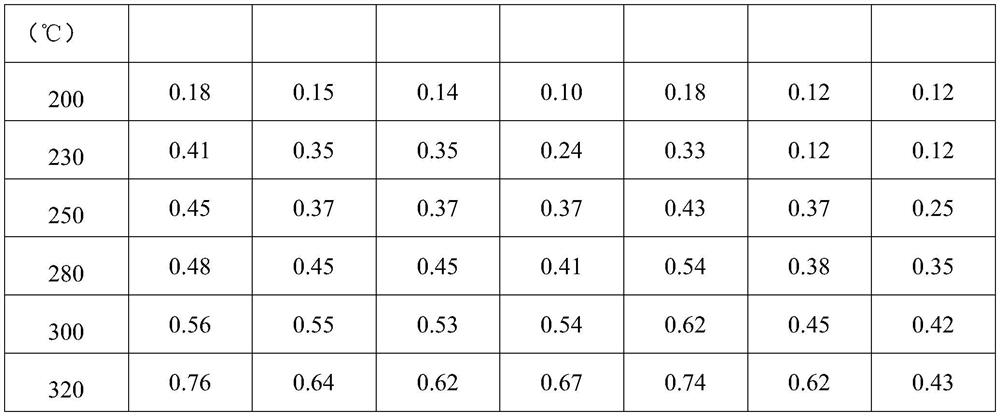

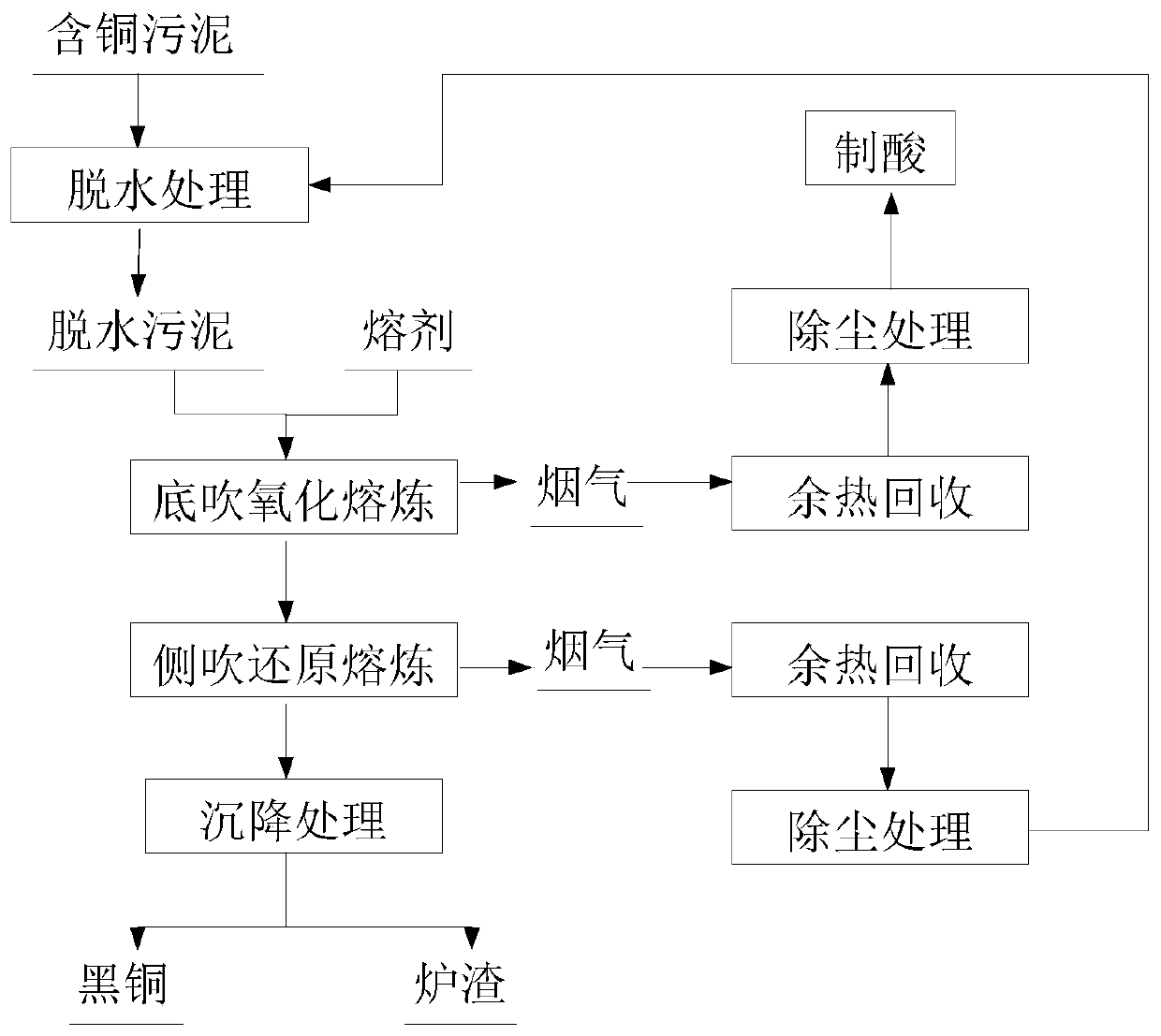

Method and device for producing black copper by sludge containing copper

The invention provides a method and device for producing black copper by sludge containing copper. The method comprises the following steps that S1, the sludge containing copper is dewatered to the water content of 10-40wt% to form dewatered sludge; S2, the dewatered sludge is mixed with a fusing agent to be subjected to bottom blowing oxidation smelting in a full-slag smelting pool to form oxidizing smelting slag; S3, the oxidizing smelting slag is subjected to side blowing reduction smelting in a reduction smelting pool to obtain a reduced smelting product; and S4, the reduced smelting product is subjected to sedimentation treatment to obtain the black copper and furnace slag. According to the method and device for producing the black copper by the sludge containing copper, the sludge containing copper is treated by using the technology, the problems of long process, high tailing copper content, high sulfur content and the like when the copper is recycled from the sludge containing copper in the prior art are effectively solved, and the recovery rate of valuable metal is improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

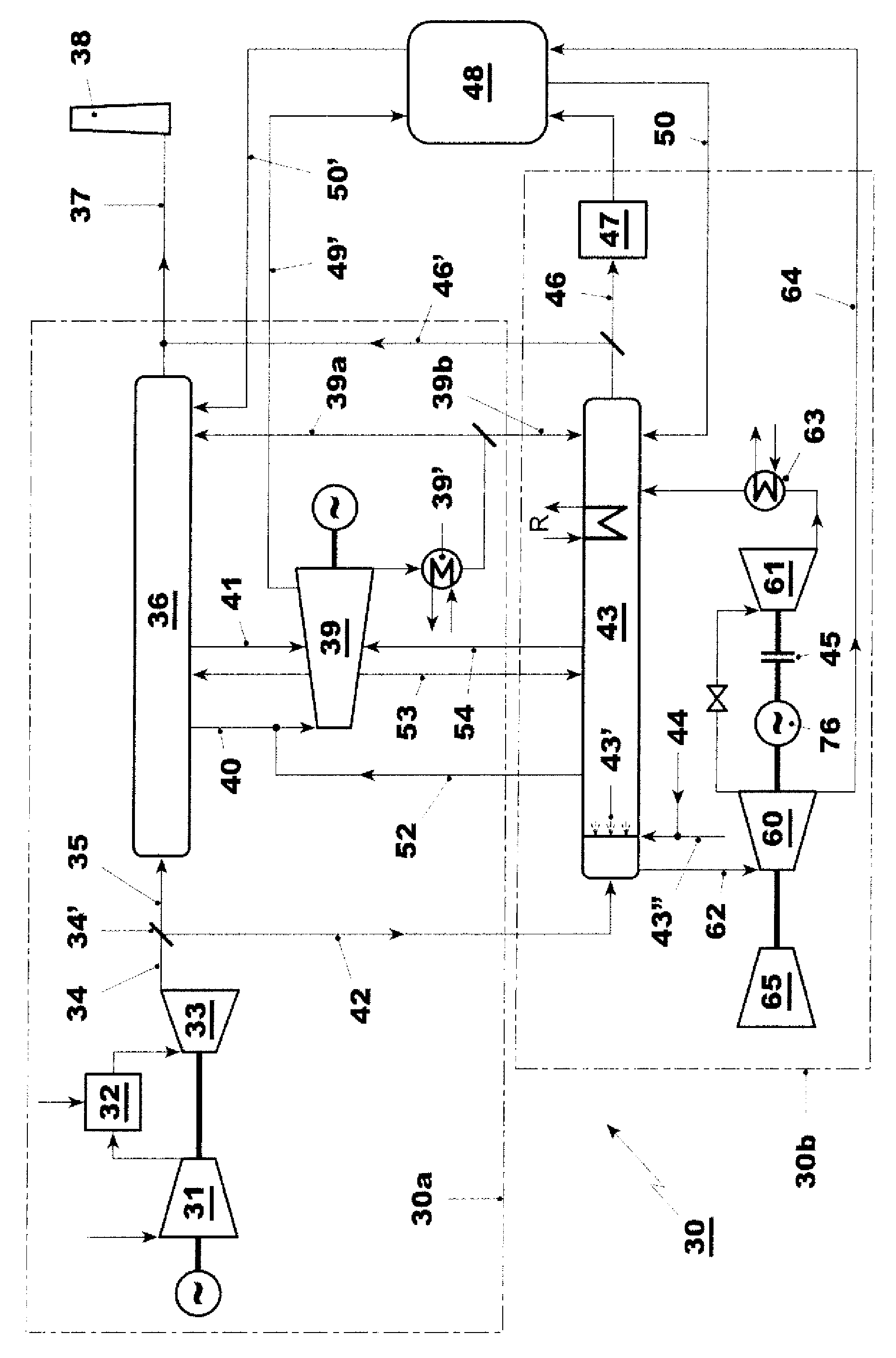

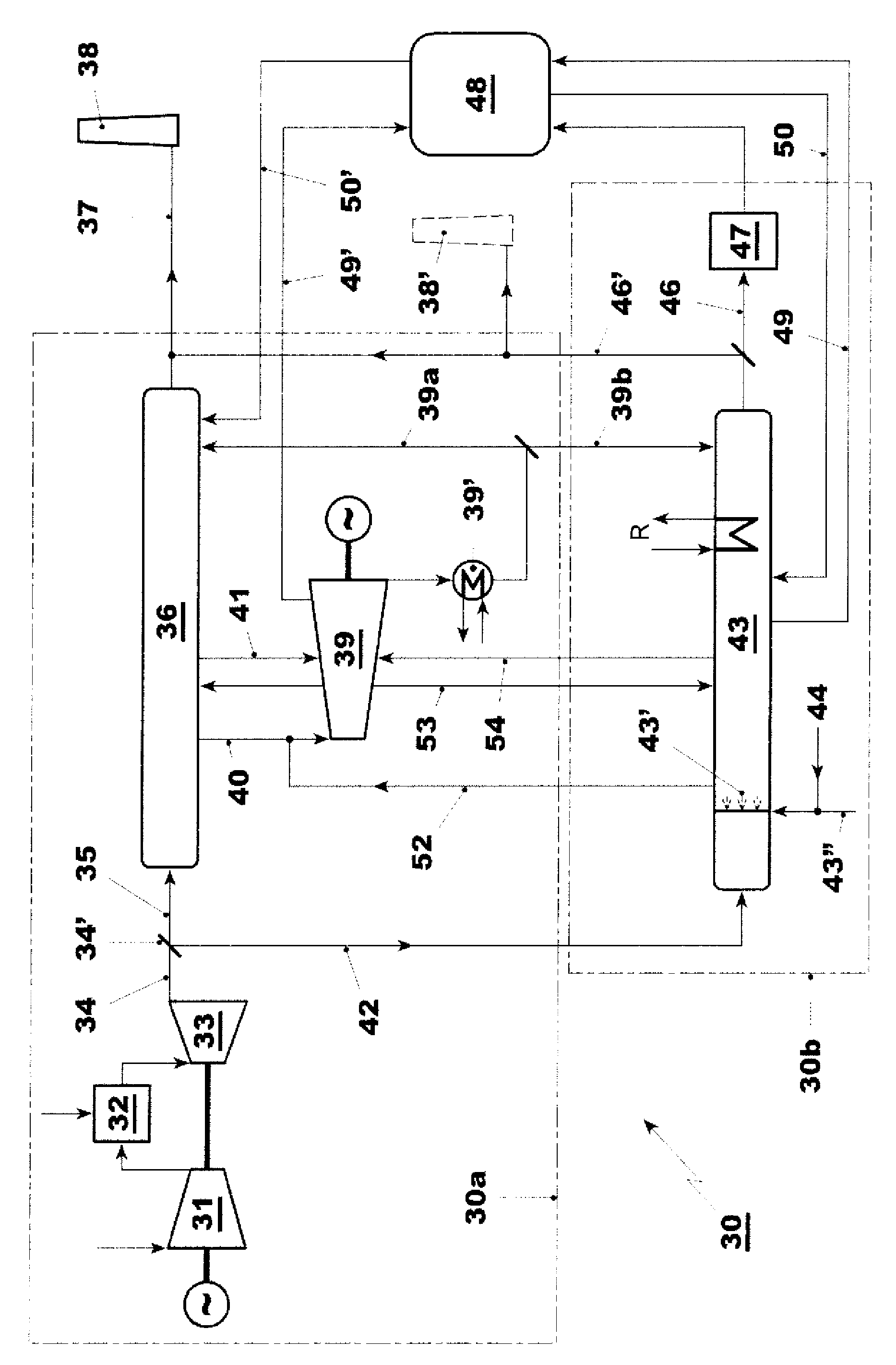

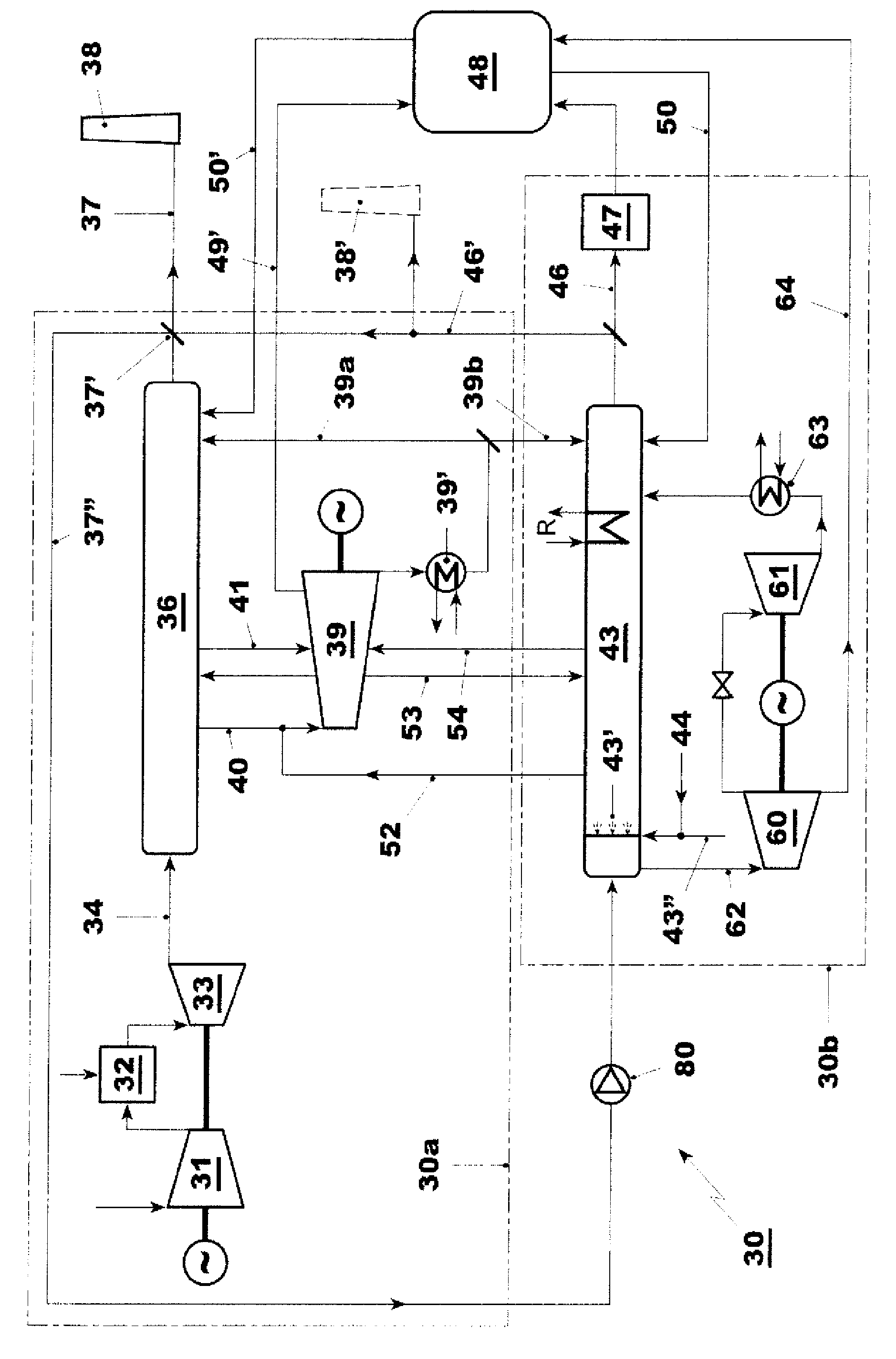

Combined cycle power plant with CO2 capture and method to operate it

InactiveCN103228890AImprove performanceGood income effectSteam useGas turbine plantsEngineeringPlant efficiency

A combined cycle power plant with a gas turbine, steam turbine, and first HRSG comprises a CO2 capture plant for the at least partial capture of CO2 from the exhaust gases from the gas turbine. It comprises in particular a second HRSG or boiler arranged to receive a portion of the exhaust gases and transfer its heat to steam and feedwater. Steam generated in the second HRSG or boiler is used for the operation of the CO2 capture plant and / or to operate a steam turbine that drives a generator and optionally a CO2 compressor. The power plant according to the invention allows for greater flexibility in power plant part load control and power plant efficiency. A method to operate the power plant is also claimed.

Owner:ALSTOM TECH LTD

Antifouling anti-dazzle display glass and preparation method thereof

InactiveCN107540240AHigh viscosityWith photocatalytic self-cleaning functionNanoparticleWear resistance

The invention relates to the technical field of display glass, especially to antifouling anti-dazzle display glass and a preparation method thereof. The display glass contains a transparent glass substrate and an antifouling anti-dazzle film which is formed after an antifouling AG solution is sprayed onto the surface of the transparent glass substrate and solidified. The surface of the antifoulinganti-dazzle film has an uneven microstructure. The antifouling AG solution contains 3-8% of nano-TiO2 / SiO2, 80-86% of ethanol and 6-12% of petroleum ether. The nano-TiO2 / SiO2 is a core-shell hollow structured spherical nanoparticle with TiO2 as the core and porous SiO2 as the shell, and there is a 2nm-3nm nano-space layer between the core and the shell. The preparation method comprises steps as follows: preparation of nano-TiO2 / SiO2, preparation of the antifouling AG solution, and spraying and solidification for film formation. According to the preparation method, the antifouling AG solutionis sprayed onto the transparent glass substrate and solidified to form the antifouling anti-dazzle film which is not easy to fall off, and then the antifouling anti-dazzle display glass which is durable in use and has excellent wear resistance is prepared.

Owner:CHONGQING ZHONGGUANGDIAN DISPLAY TECH CO LTD

Production method of nano calcium carbonate

InactiveCN107473253AIncrease concentrationHigh volume concentrationCalcium/strontium/barium carbonatesCarbon compoundsManufacturing technologyFiltration

The invention discloses a production method of nano calcium carbonate, and belongs to the technical field of calcium carbonate manufacturing. The production method comprises the steps of calcination, digestion, size mixing, carbonization, coating, filtration and drying. In the calcination process, CO2 in kiln gas is separated and is liquefied and canned to obtain a CO2 output tank; the carbonization process comprises first carbonization, screening and second carbonization; the first carbonization is conducted in a first carbonization tank, CO2 is input through the CO2 output tank, compared with traditional kiln gas input, the concentration of CO2 in the first carbonization tank is increased, and the reaction cycle is shortened; through the arrangement of a first circulation pipeline in the first carbonization tank, a fine slurry in a first inner cavity is in sufficient contact with CO2, and the reaction cycle is further shortened; the second carbonization is conducted in a second carbonization tank, and the structure of the second carbonization tank is the same as that of the first carbonization tank. The production method of nano calcium carbonate solves the problem that the product is wide in particle size distribution and long in production cycle in a traditional nano calcium carbonate manufacturing technology.

Owner:广西华洋矿源材料有限公司

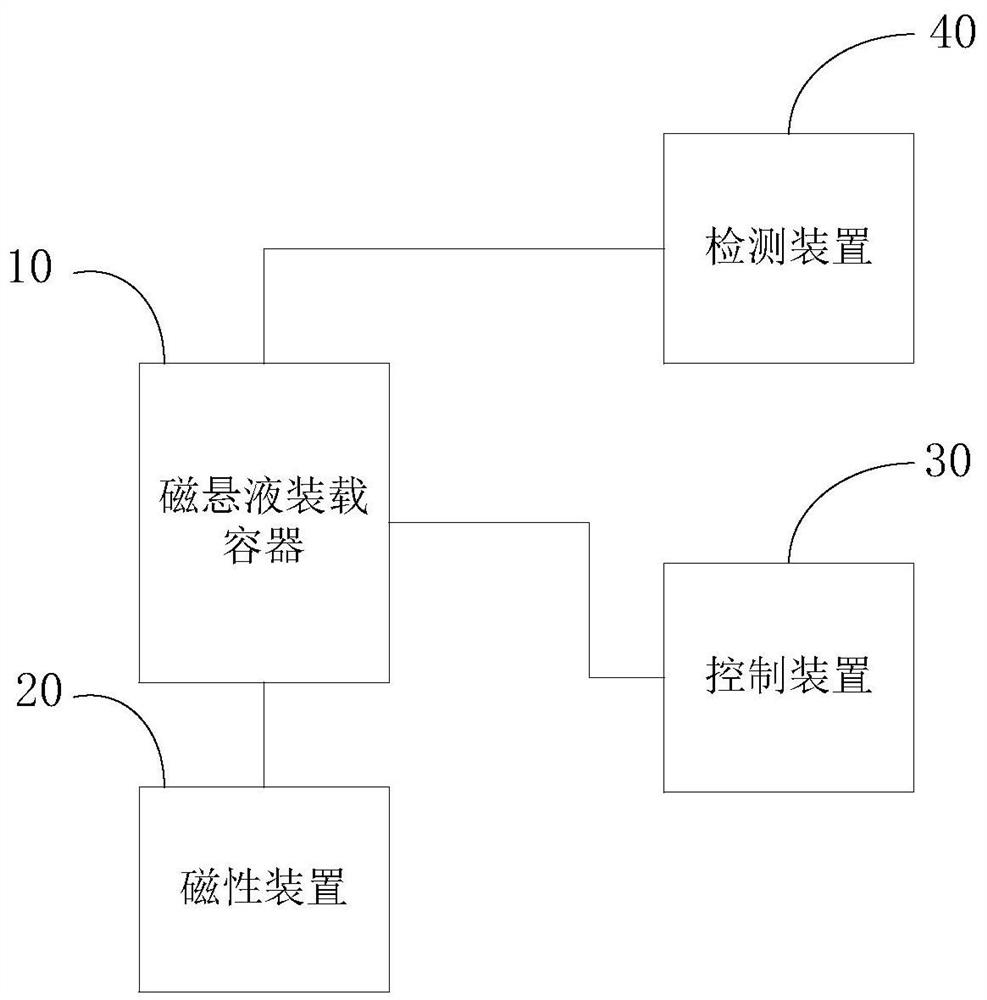

Magnetic suspension volume concentration detection method and detection system and magnetic powder flaw detection system

PendingCN114062211AShorten the timeHigh volume concentrationVolume measurement apparatus/methodsParticle suspension analysisEngineeringMechanical engineering

The embodiment of the invention provides a magnetic suspension volume concentration detection method and detection system and a magnetic powder flaw detection system. According to the specific implementation scheme, the detection system comprises a magnetic suspension loading container, a magnetic device, a control device and a detection device; the control device is detachably connected with the magnetic suspension loading container; the magnetic device is positioned below the bottom of the magnetic suspension loading container; the control device is used for controlling the magnetic suspension loading container to obtain a to-be-detected magnetic suspension with a preset volume from the magnetic particle flaw detector; the magnetic suspension loading container is used for loading the to-be-detected magnetic suspension; the magnetic device is used for adsorbing magnetic powder in the to-be-detected magnetic suspension to the bottom of the magnetic suspension loading container within preset time; and the detection device is used for acquiring volume data of the magnetic powder in the magnetic suspension loading container and volume data of the to-be-detected magnetic suspension, and calculating the volume concentration of the magnetic suspension. The detection system provided by the embodiment of the invention improves the efficiency of detecting the volume concentration of the magnetic suspension.

Owner:CRRC SHENYANG CO LTD

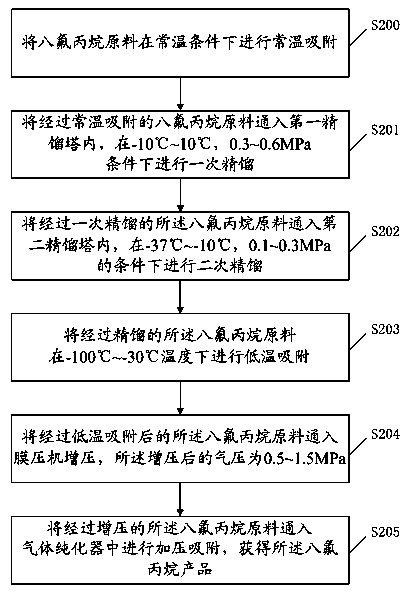

A kind of octafluoropropane purification method

ActiveCN103664502BHigh purityHigh selectivityHalogenated hydrocarbon separation/purificationPurification methodsDistillation

The invention discloses an octafluoropropane purifying method. The octafluoropropane purifying method comprises the following steps: carrying out normal-temperature adsorption on an octafluoropropane material under a normal-temperature condition; carrying out distillation on the octafluoropropane material adsorbed at the normal temperature under conditions with the temperature of -37 DEG C-10 DEG C and pressure of 0.1 MPa-0.6 MPa; carrying out low-temperature adsorption on the distilled octafluoropropane material at the temperature ranging from-100 DEG C to -30 DEG C; carrying out pressurized adsorption on the low-temperature adsorbed octafluoropropane material under the pressure condition of 0.5 MPa-1.5 MPa to obtain an octafluoropropane product. The octafluoropropane purifying method disclosed by the invention is adopted, so that not only most of fluorine-chlorine-carbon compound-containing impurities are removed, but also a problem that removing depth for carbon dioxide and carbon in the prior art is not enough is solved, thus energy consumption is lowered, adsorption effect of an adsorbent is strengthened and the purity of the octafluoropropane product is over 99.999%.

Owner:FOSHAN HUATE GASES +1

A kind of purification method of hexafluoroethane

ActiveCN103664501BHigh puritySolve storage problemsHalogenated hydrocarbon separation/purificationHexafluoroethanePurification methods

The invention discloses a hexafluoroethane purification method which comprises the following steps: rectifying a hexafluoroethane raw material under the conditions of (-70)-(-35) DEG C and 0.1-1 MPa; performing low-temperature adsorption on the rectified hexafluoroethane raw material under the temperature conditions of (-100)-(-70) DEG C; and performing pressurized adsorption on the hexafluoroethane raw material after low-temperature adsorption under the pressure conditions of 0.5-1.5 MPa, thus obtaining the hexafluoroethane product, wherein the CO2 volume concentration of the hexafluoroethane product is no more than 0.5 ppm, and the H2O volume concentration is no more than 1 ppm. According to the invention, the problem that potential safety hazard is caused due to insufficient CO2 and H2O removal depth and introduction of anhydrous HCl in hexafluoroethane is solved, the energy consumption is reduced, and the adsorption effect of adsorbent is enhanced; and the purity of the hexafluoroethane product is up to 99.9995% or above, thus meeting the requirements for electronic specific gas in the semiconductor and micro-electronics industry.

Owner:FOSHAN HUATE GASES +1

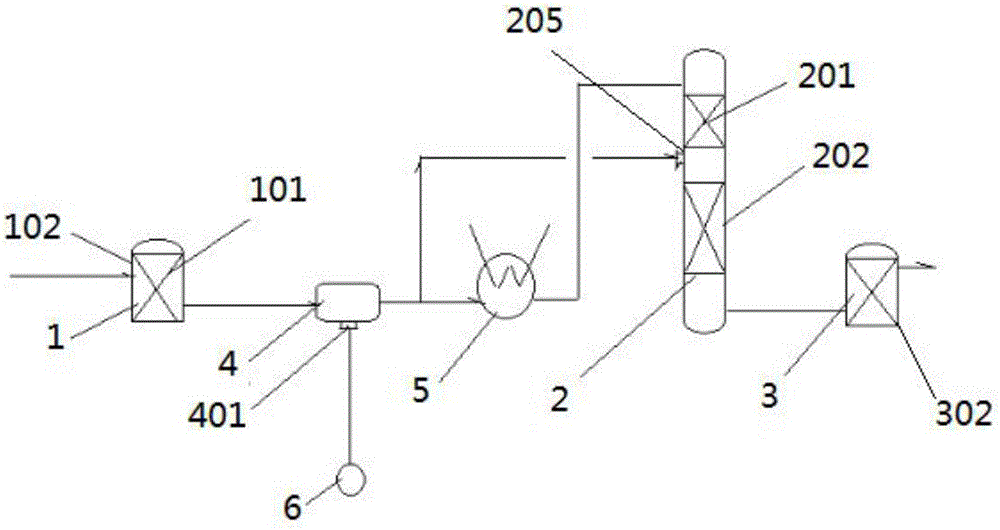

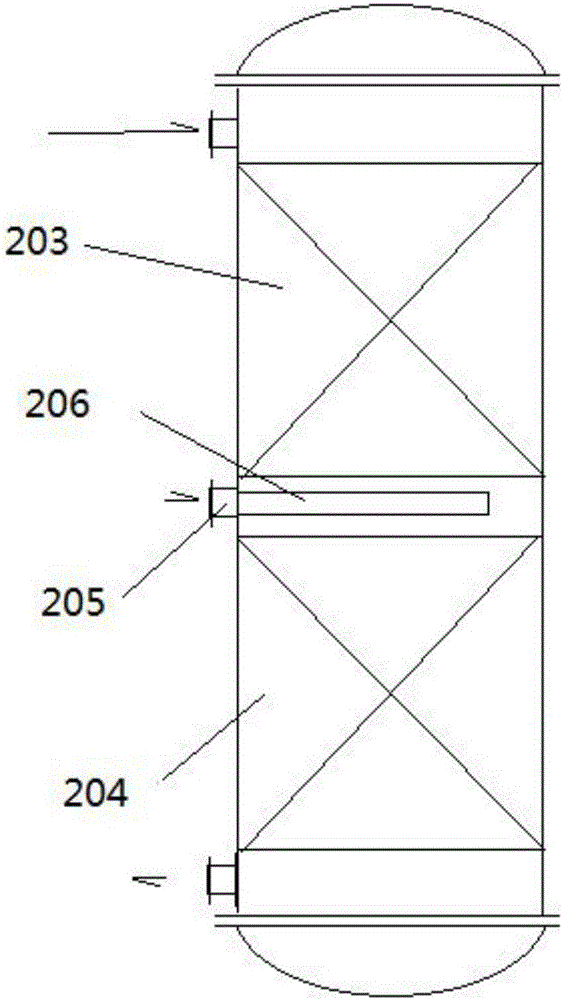

Device and method for collecting nitrogen gas from cyclohexane oxidized tail gas

ActiveCN106082145AReduce consumptionEmission reductionNitrogen purification/separationSpecific gas purification/separationCatalytic oxidationNitrogen gas

The invention provides a device and method for collecting nitrogen gas from cyclohexane oxidized tail gas. The device comprises a variable temperature adsorption device, a middle mixer, a heating device, a catalytic oxidation device and a variable pressure adsorption device which are connected in series sequentially through pipelines, wherein the variable temperature adsorption device is provided with a variable temperature adsorption agent layer; the middle mixer is provided with an air inlet connected with a compressed air source; the variable pressure adsorption device is provided with a variable pressure adsorption agent layer; the variable temperature adsorption device comprises a variable temperature adsorber which is provided with a variable temperature adsorption gas outlet and an oxidized tail gas inlet communicating with an inner cavity; the catalytic oxidation device comprises a catalytic oxygenizer provided with a catalyst bed layer; the catalytic oxygenizer is provided with a catalytic oxidation gas outlet and a variable temperature adsorption gas inlet communicating with the inner cavity of the catalytic oxygenizer; the variable temperature adsorption device comprises a variable temperature adsorber which is provided with a purified gas outlet and a catalytic oxidation gas inlet communicating with the inner cavity. The device and the method have the advantages that the nitrogen gas with the volume concentration being 99.9 percent or higher can be obtained; materials can be recovered; the consumption of public works is also reduced; meanwhile, the flare gas emission quantity is reduced.

Owner:CHONGQING HUAFON CHEM +1

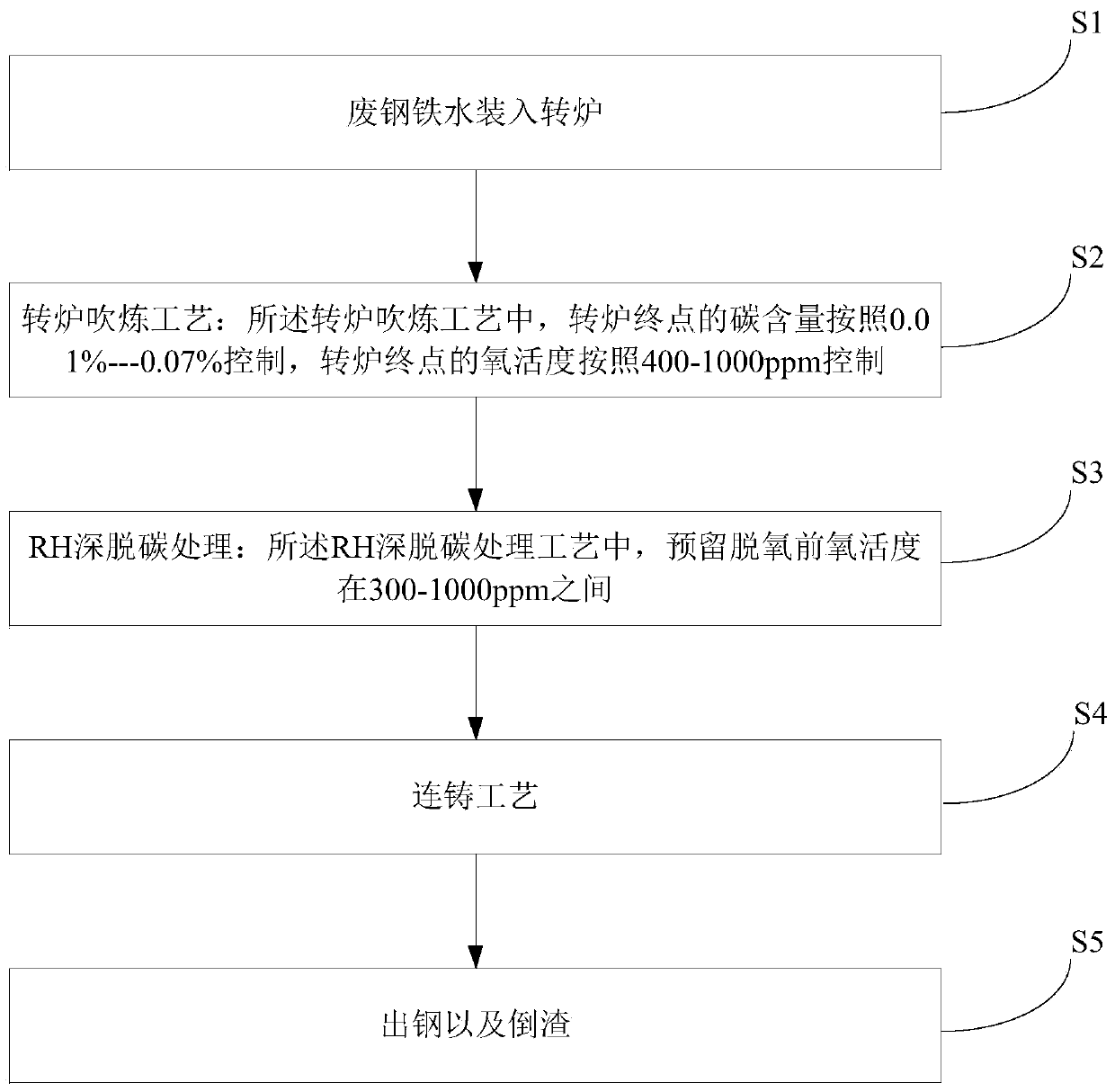

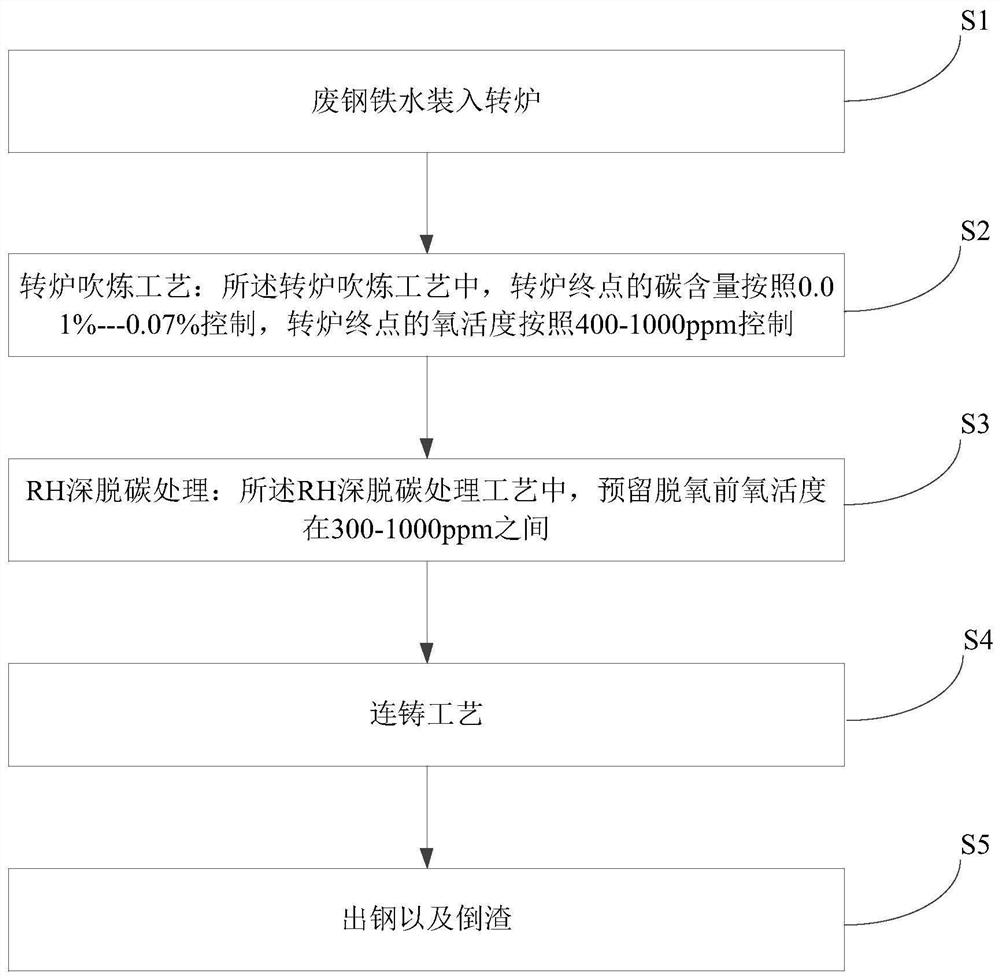

Smelting method for decreasing blockage probability of high-aluminum molten steel gap

ActiveCN109735677AHigh volume concentrationImprove blockageManufacturing convertersSlagHigh aluminum

The invention belongs to the technical field of metallurgy and particularly relates to a smelting method for decreasing the blockage probability of a high-aluminum molten steel gap. The smelting method comprises the steps that scrap molten iron and steel is loaded into a converter; a converter blowing process is conducted, specifically, in the converter blowing process, the carbon content at the end point of the converter is controlled to be 0.01%-0.07%, and the oxygen activity at the end point of the converter is controlled to be 400-1000 ppm; RH deep decarbonization treatment is conducted, specifically, in an RH deep decarbonization treatment process, the oxygen activity before deoxidation is reserved to be 300-1000 ppm; a continuous casting process is conducted; and tapping and slag pouring are conducted. According to the smelting method, the phenomenon of blockage of the high-aluminum molten steel gap is avoided by controlling the oxygen activity of the converter blowing process, ladle slag does not need to be modified, the cost is saved, inclusion modifiers such as calcium modifiers or rare earth modifiers do not need to be added into the molten steel, thus on the one hand, the cost is saved, on the other hand, the situation that molten steel gap nodulation is aggravated due to mismatching of the dosage of the inclusion modifiers and molten steel compositions is avoided, and the process effect is more stable.

Owner:BEIJING SHOUGANG CO LTD

Stain Resistant Matte Elastomeric Coatings

ActiveCN104293059BSolve the problem of sticking back at high temperaturePrevent high temperature sticking backCoatingsEmulsionCrack resistance

The invention provides a stain-resistant matte elastic paint. The stain-resistant matte elastic paint comprises the following components in parts by weight: 10-15 parts of water, 0.2-0.5 part of wetting agent, 0.3-0.5 part of modified dispersant, 15-20 parts of titanium dioxide powder, 8-10 parts of talc powder, 8-10 parts of kaolin, 40-45 parts of a pure acrylic elastic emulsion, 3-5 parts of an environment-friendly additive, 3-3.5 parts of a coalescent agent, 0.3-0.4 part of a defoamer, 0.4-0.8 part of a thickener and 5-10 parts of lignin, wherein the environment-friendly additive comprises a stain resisting agent. The stain-resistant matte elastic paint provided by the invention is reasonably matched and combined according to the respective property characteristics of the materials. The paint film is presented into a core-shell structure with soft interior and hard exterior due to the application of an active balancing technology and the combination of the functions of active particles and the elastic emulsion, so that the paint film simultaneously has the properties of high-temperature after-tack resistance, stain resistance and crack resistance.

Owner:ASIA PAINT SHANGHAI

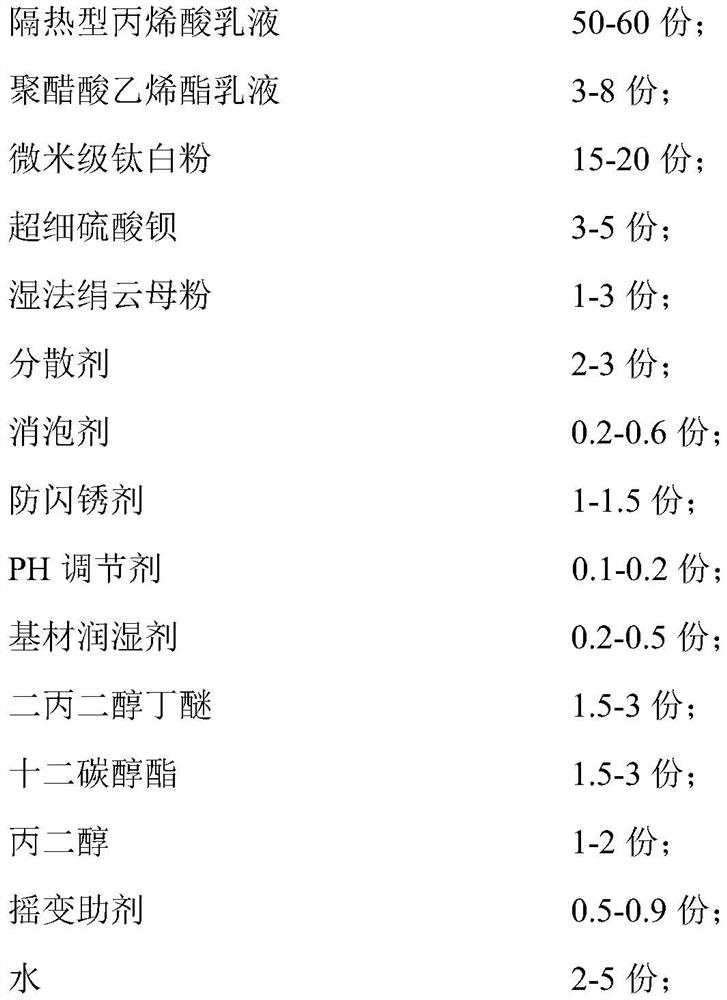

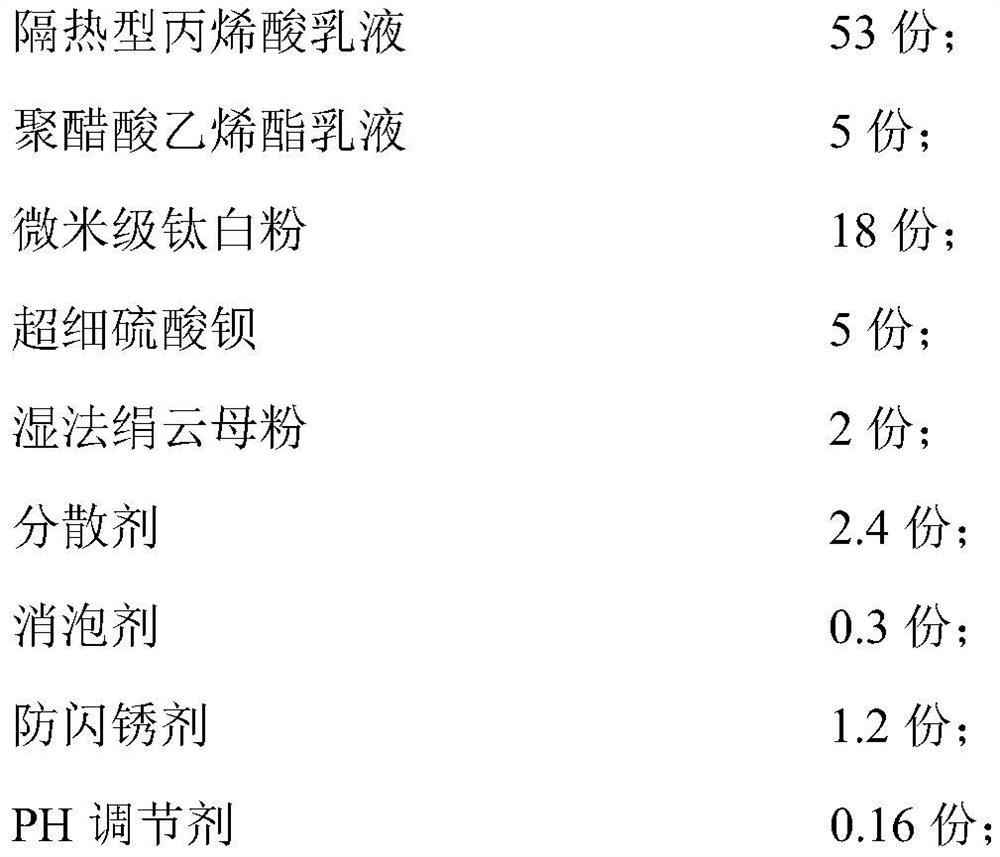

Heat-insulation cooling type water-based mixed paint and preparation method thereof

InactiveCN112239615AGood heat insulation and cooling effectLow VOCReflecting/signal paintsPolyvinyl acetateCarvacryl acetate

The invention provides a heat-insulation cooling type water-based mixed paint and a preparation method thereof. The heat-insulation cooling type water-based mixed paint is prepared from the followingraw materials in parts by weight: 50-60 parts of heat-insulating acrylic emulsion, 3-8 parts of polyvinyl acetate emulsion, 15-20 parts of micron-sized titanium dioxide, 3-5 parts of superfine bariumsulfate, 1-3 parts of wet sericite powder, 2-3 parts of a dispersing agent, 0.2-0.6 part of a defoaming agent, 1-1.5 parts of a flash-rust inhibitor, 0.1-0.2 part of a pH regulator, 0.2-0.5 part of abase material wetting agent, 1.5-3 parts of dipropylene glycol butyl ether, 1.5-3 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 1-2 parts of propylene glycol, 0.5-0.9 part of a shaking auxiliary agent and 2-5 parts of water; wherein the particle size of the micron-sized titanium dioxide is 1.58 [mu]m. The heat-insulation cooling type water-based mixed paint has the advantages of good heat-insulating and cooling effects, low VOC, environmental friendliness and the like, is suitable for the surface of an outdoor metal material, and plays a role in protection and cooling.

Owner:东莞大宝化工制品有限公司 +2

A kind of masterbatch grade titanium dioxide and preparation method thereof

ActiveCN112646396BAvoid direct contactGood weather resistancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsOrganic filmOil emulsion

The invention provides a color masterbatch grade titanium dioxide, the titanium dioxide includes an inner core and a coating layer coated on the inner core, the inner core is titanium dioxide, and the coating layer includes a first coating layer coated on the inner core An organic film layer, an inorganic film layer coated on the first organic film layer, and a second organic film layer coated on the inorganic film layer. The preparation method of titanium dioxide includes beating and dispersing, first organic coating, agent-free coating, pressure filtration and second organic coating. In the present invention, the surface is coated and modified by organic matter in the slurry state before the inorganic surface is coated, which greatly improves the compatibility of titanium dioxide in the application system; the amino silicone oil emulsion is used for further surface modification in the flash drying link. To enhance the compatibility and bonding force between the powder particles and the resin; adding silane coupling agent in the steam crushing process is a further modification, so that the titanium dioxide particles are completely hydrophobic and lipophilic.

Owner:攀枝花大互通钛业有限公司

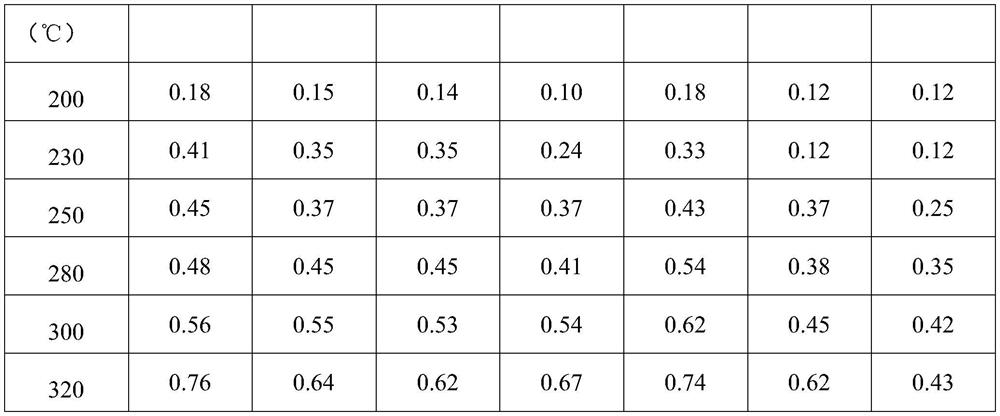

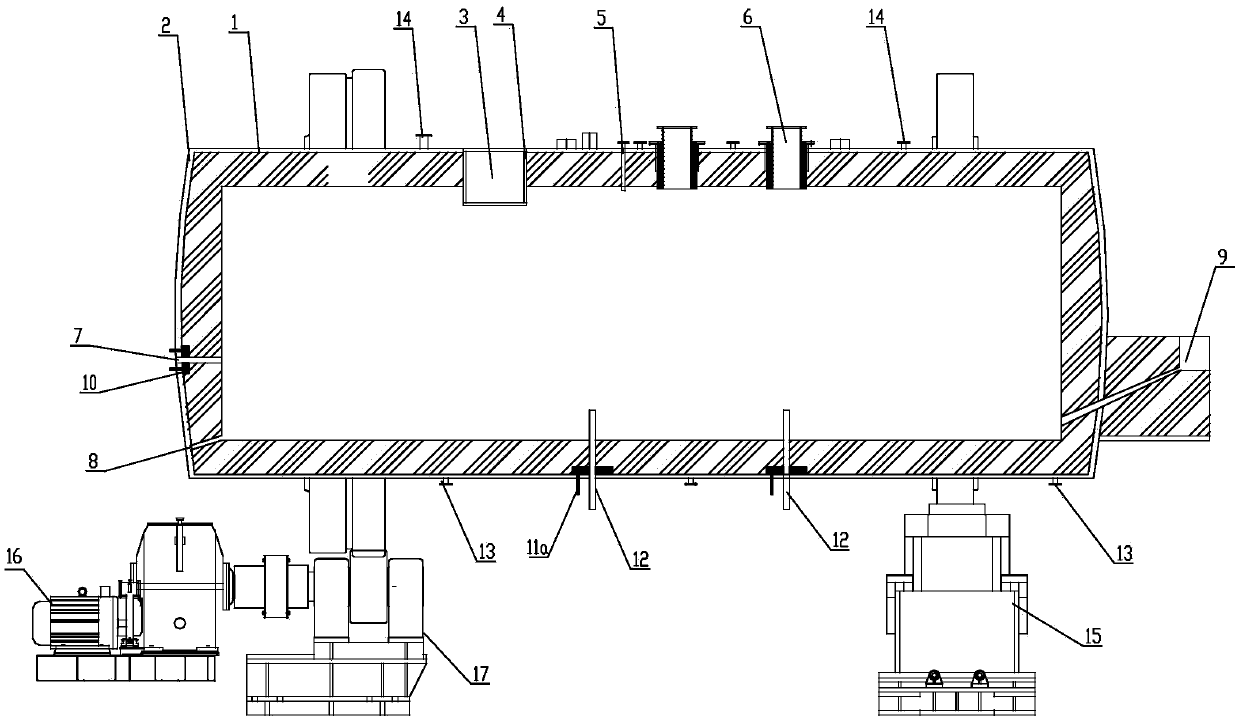

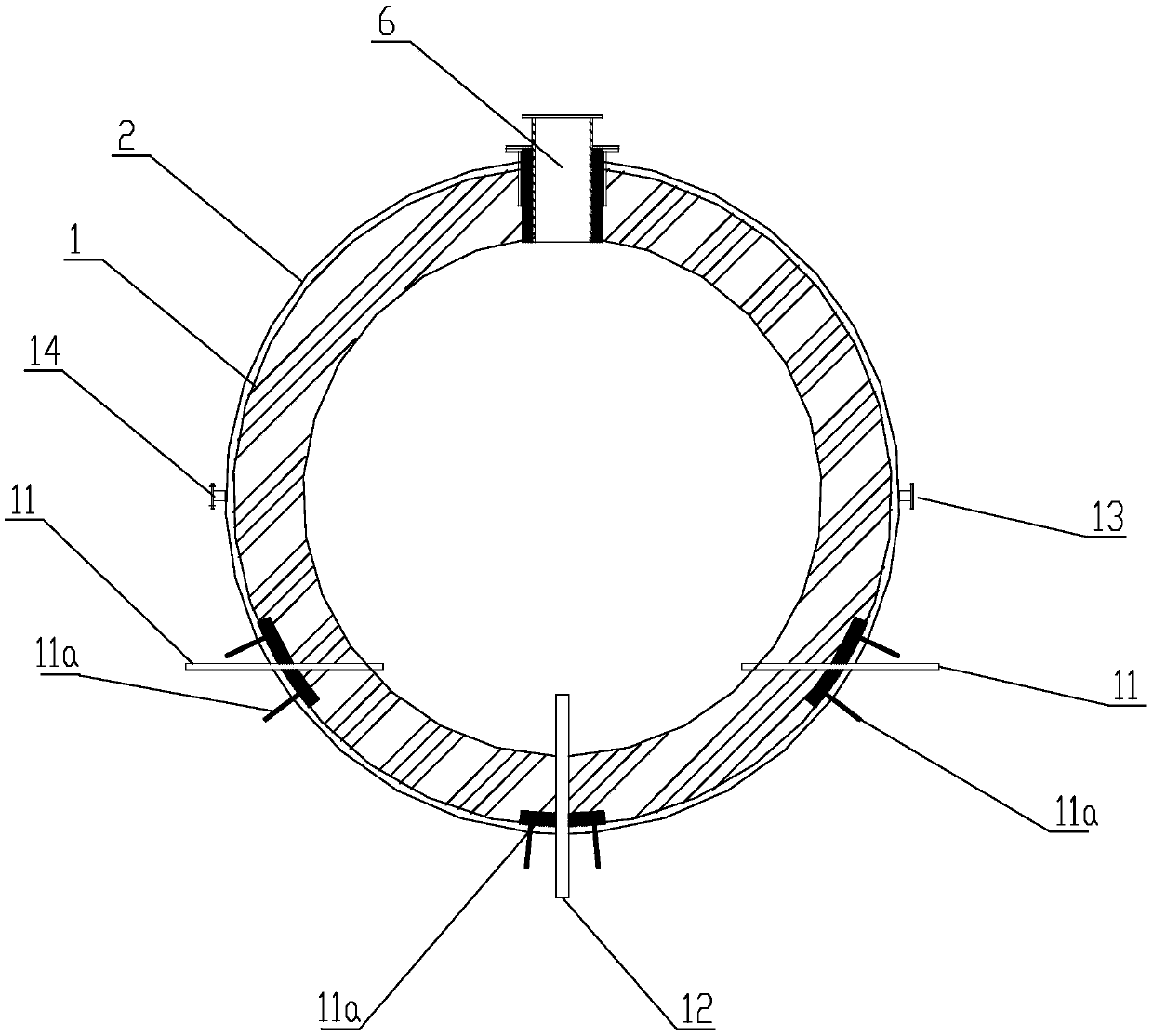

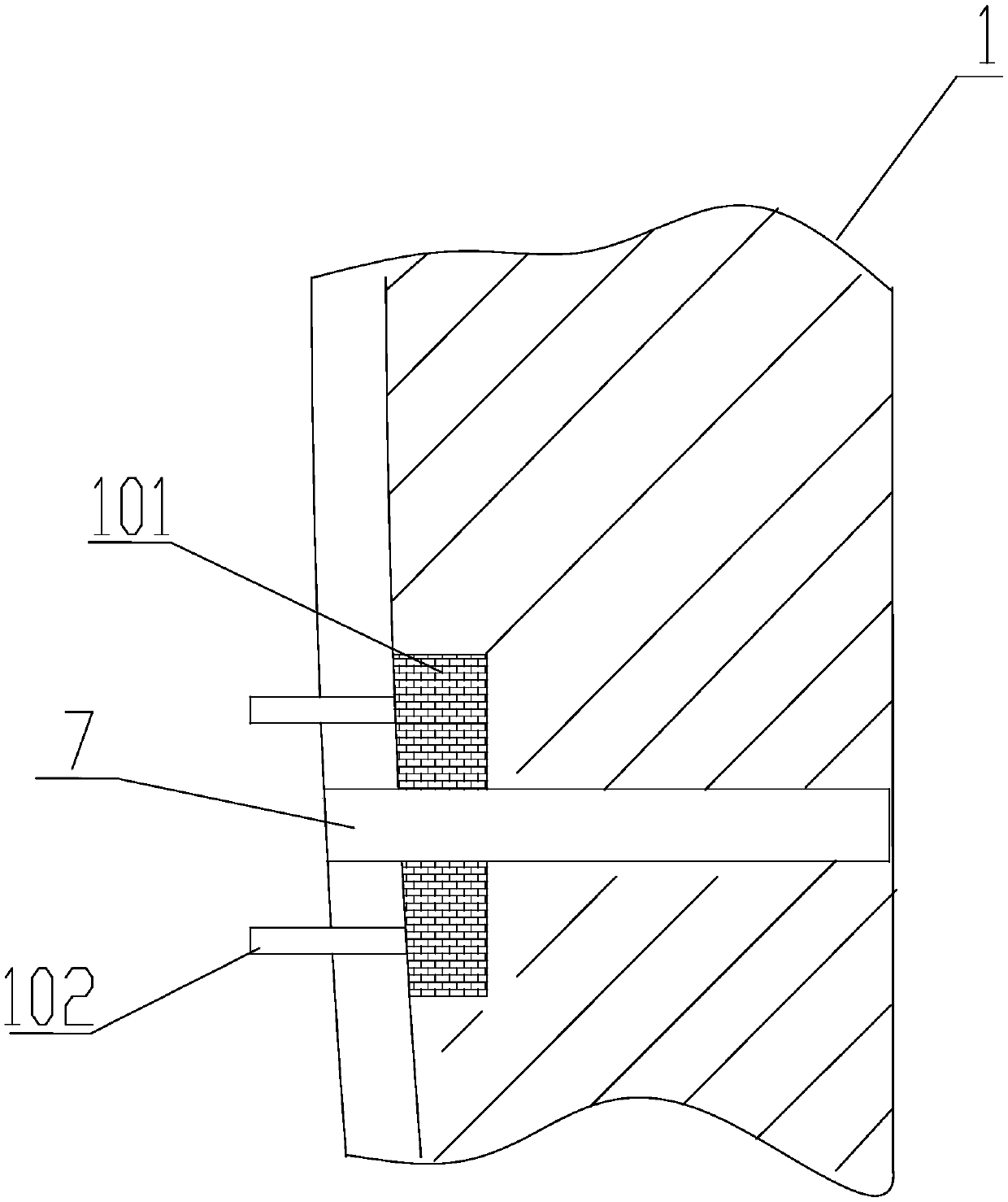

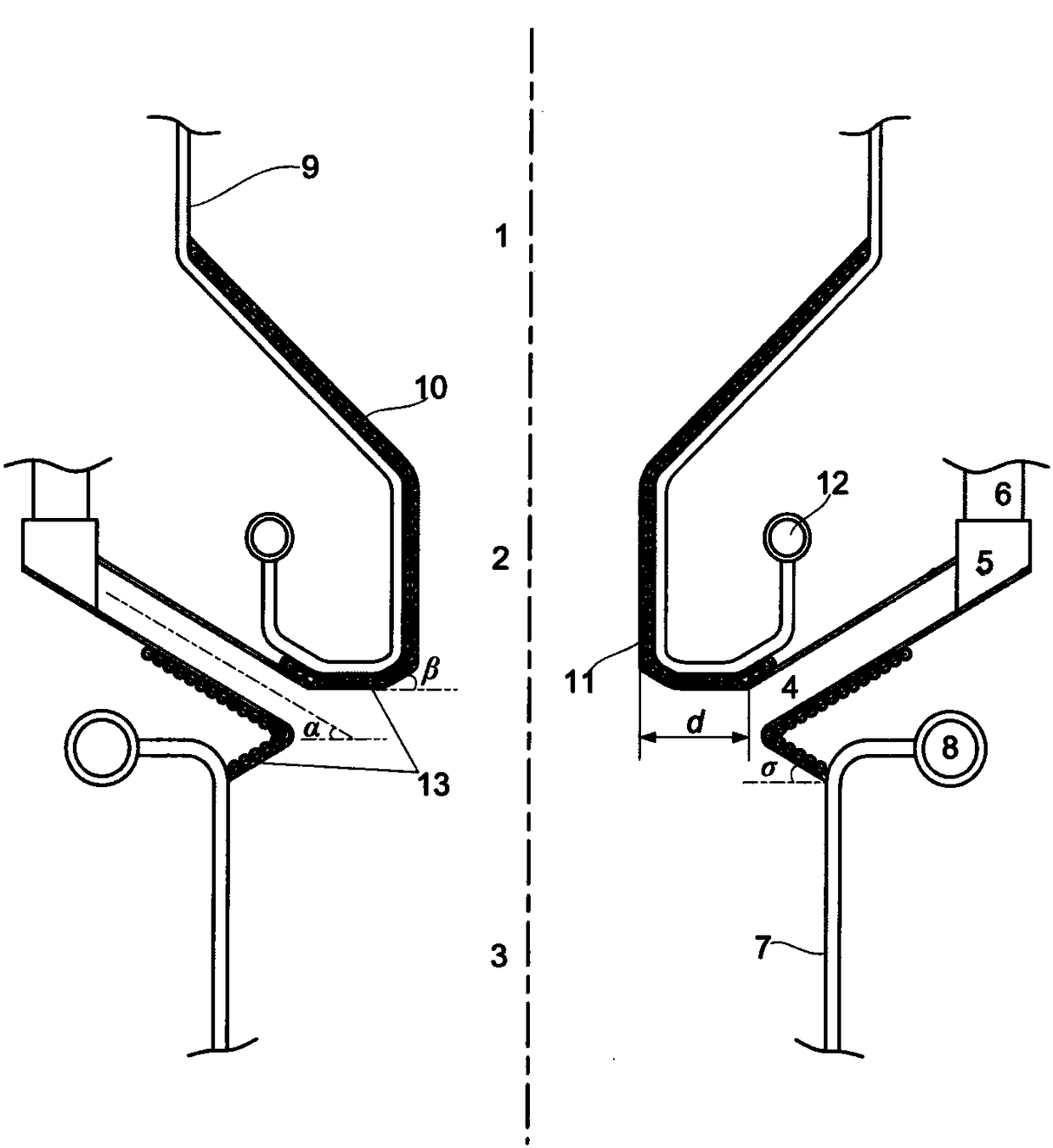

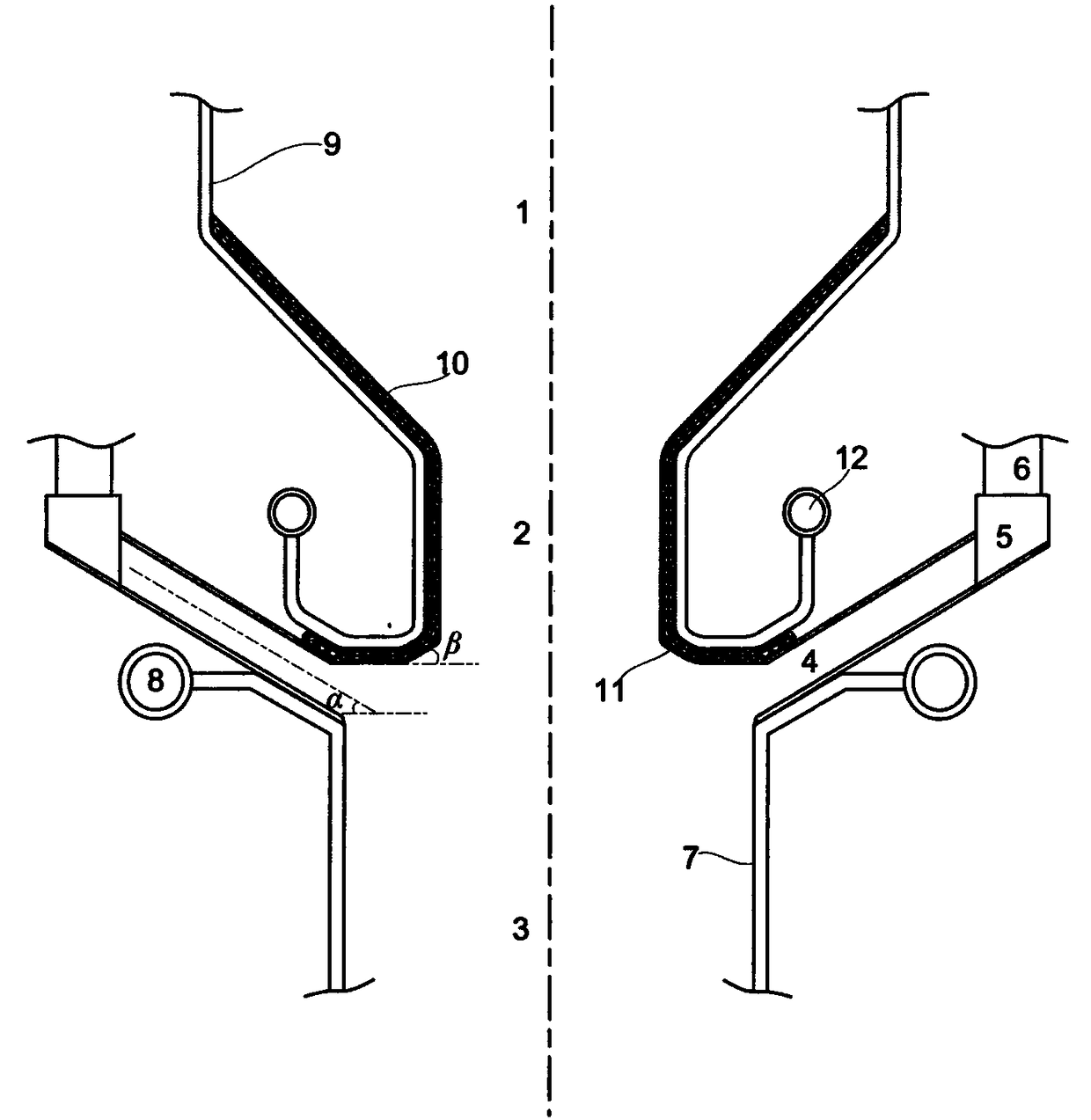

Oxygen-enriched oxidation smelting method and device for antimony-containing material

ActiveCN106916966BVolatilization and oxidation reactions are fastHigh volume concentrationProcess efficiency improvementSlagMixed materials

The invention discloses an oxygen-enriched oxidation smelting method for an antimony-containing material. The oxygen-enriched oxidation smelting method comprises the following steps: (1) mixing: uniformly mixing the antimony-containing material with an auxiliary material according to a certain ratio to obtain a mixed material; (2) pelletizing: pelletizing the mixed material, and delivering pellets into an oxygen-enriched oxidation smelting device; (3) air blasting: after carrying out thermal decomposition on the mixed material for 1-5min, introducing oxygen-enriched air with the oxygen volume concentration of 40-90% and the preheating temperature of higher than or equal to 700 DEG C into a furnace; (4) smelting: controlling the temperature and pressure inside the furnace, and producing a primary high-temperature melt, liquid high-antimony mineral slag and dust-laden gases after smelting; and (5) dust and gas recovery. The oxygen-enriched oxidation smelting method is high in oxidation degree and capable of increasing the recovery rate and reducing the energy consumption while reducing pollution; and the invention also provides the oxygen-enriched oxidation smelting device capable of conveniently and rapidly controlling the reaction atmosphere and temperature in a furnace body and has the characteristics of simple structure, good sealing performance and high raw material adaptability.

Owner:广西生富锑业科技股份有限公司

A smelting method for reducing the clogging probability of high aluminum steel nozzle

The invention belongs to the technical field of metallurgy, and in particular relates to a smelting method for reducing the clogging probability of a high-aluminum steel nozzle. The smelting method includes: loading molten steel scrap into a converter; converter blowing process: in the converter blowing process, the carbon content at the end of the converter is controlled according to 0.01%-0.07%, and the oxygen activity at the end of the converter is controlled according to 400-1000ppm Control; RH deep decarburization treatment: In the RH deep decarburization treatment process, the reserved oxygen activity before deoxidation is between 300-1000ppm; continuous casting process; tapping and slag dumping. Because the present invention improves the clogging phenomenon of the high-alumina steel nozzle by controlling the oxygen activity of the converter blowing process, it does not need to modify the ladle slag, saves costs, and does not need to add inclusions such as calcium or rare earths to the molten steel to modify it. Quality agent, on the one hand, saves cost, on the other hand, it avoids the aggravation of nodulation at the nozzle caused by the mismatch between the amount of inclusion modifier and the composition of molten steel, and the effect of this process is more stable.

Owner:首钢股份公司迁安钢铁公司 +1

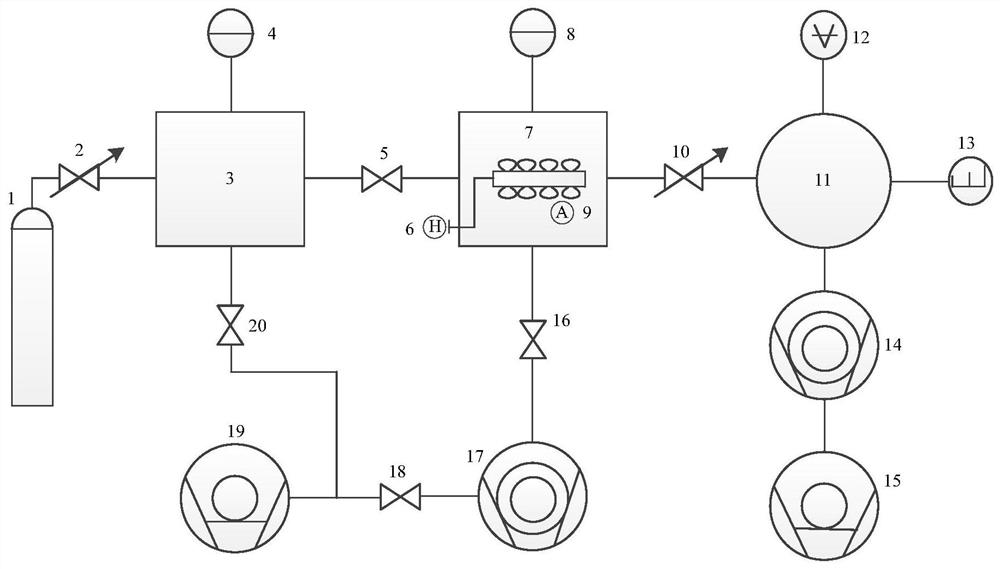

A high-pressure gas trace component detection device and method based on the principle of adsorption and enrichment

ActiveCN109752442BRealize accurate detectionAchieve content measurementMaterial analysis by electric/magnetic meansReactive gasMass Spectrometry-Mass Spectrometry

The invention discloses a high-pressure gas trace component detection device and method based on the principle of adsorption and enrichment. The detection device includes a high-pressure gas source, a slow-fill chamber, an adsorption component, a mass spectrometry analysis unit, and a vacuum pump component; the vacuum pump component is used to maintain the slow-charge The pressure required by the chamber, adsorption assembly and mass spectrometry analysis unit is connected to the slow filling chamber, adsorption assembly and mass spectrometry analysis unit through pipelines; After depressurization to normal pressure, it enters the adsorption component. Based on the principle of adsorption and enrichment, the adsorption component absorbs the trace active gas in the high-pressure gas to be measured and releases it again; the released trace active gas enters the mass spectrometry unit, and the obtained Measure the concentration of different trace active gases in high-pressure gas. The detection method of the invention does not need to prepare standard sample gas, and can realize accurate detection of trace active gas content.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

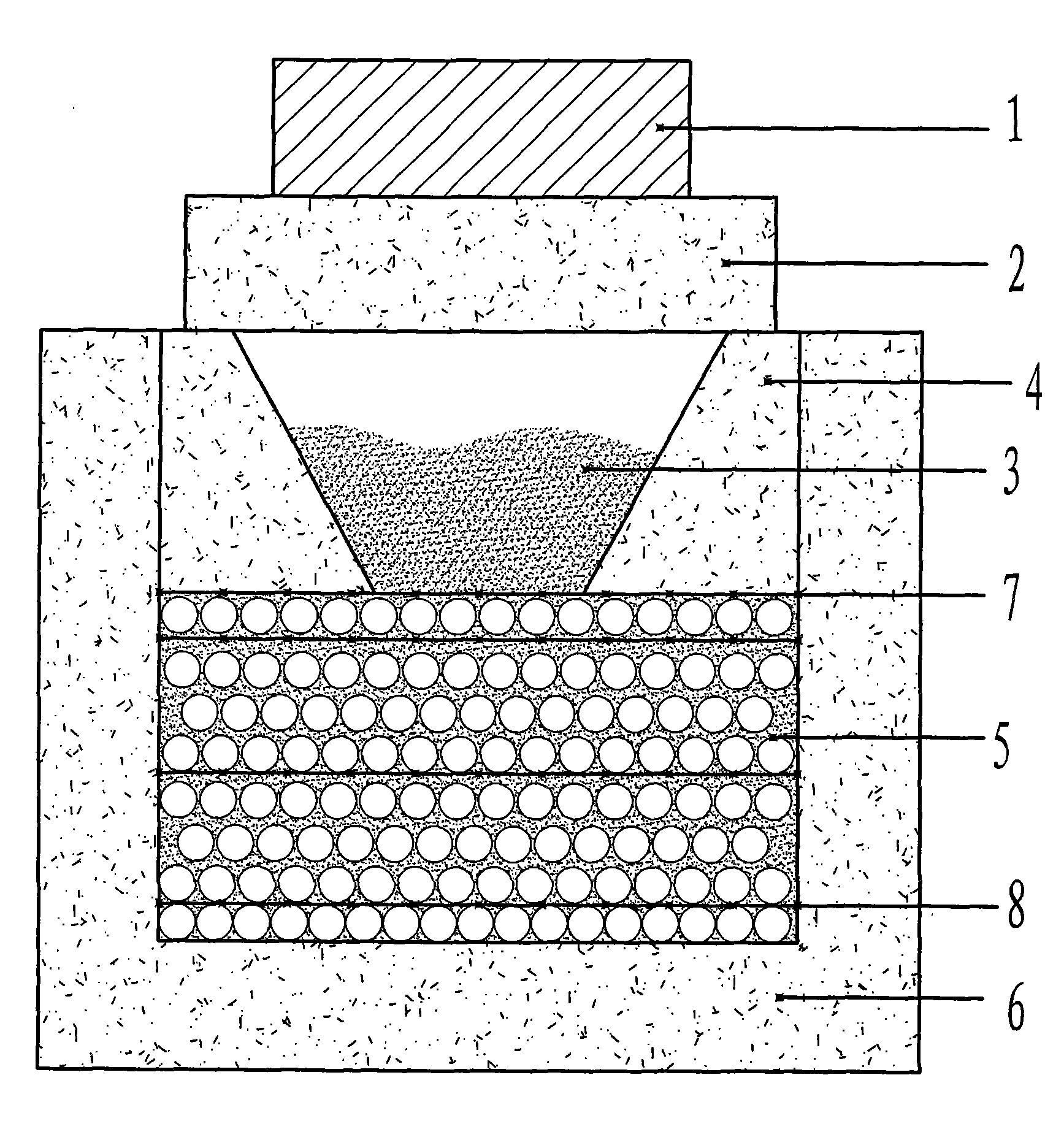

A descending high-temperature gasification product quenching device

ActiveCN105602629BSolve slaggingReduce water consumptionEnergy inputCombustible gas productionWater vaporSlag

Owner:SHANGHAI BOILER WORKS

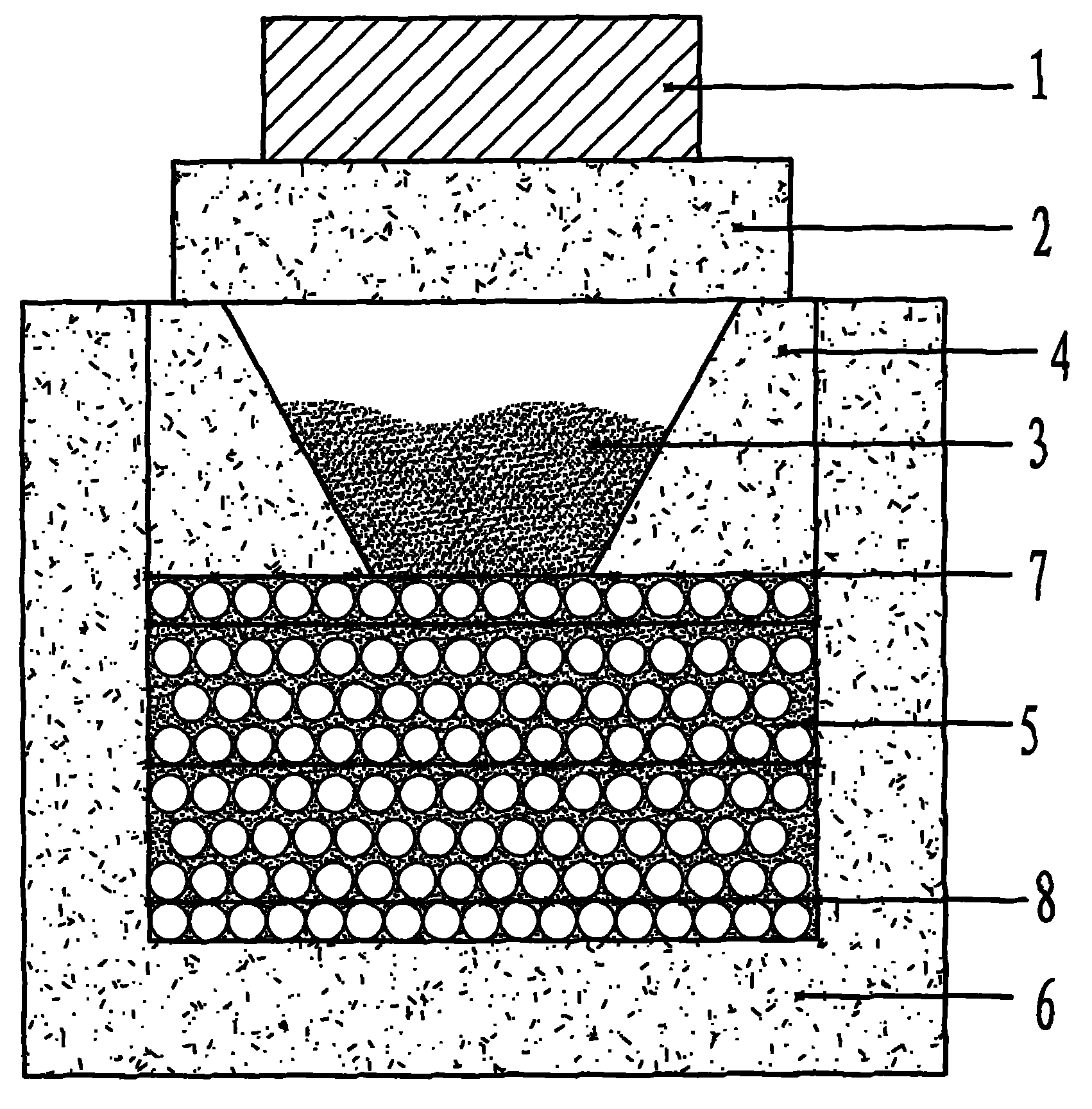

Production technology for brazing diamond polycrystal and used mold thereof

InactiveCN101591812BHigh volume concentrationImprove compactnessPolycrystalline material growthAfter-treatment detailsGraphiteUltimate tensile strength

The invention discloses production technology for a brazing diamond polycrystal and a used mold thereof. The middle part of a mold body is provided with a die cavity, the upper part of the die cavity is provided with a feeding ring, a graphite or ceramic block is arranged above the feeding ring, and a pressure block is arranged above the graphite or ceramic block. The production technology comprises the steps of: mixing a brazing material and diamond particles evenly first; then paving the mixture into the die cavity, wherein the inside of the mixture is provided with a reinforced metal mesh (wire); arranging a process metal mesh on the top of the mixture, arranging the feeding ring above the metal mesh, and adding a brazing complementary material into the ring; arranging the graphite or ceramic block above the feeding ring, and pressing the pressure block on the graphite or ceramic block; and placing the mold and the mixture into a vacuum furnace for heating, performing heat preservation for 10 to 30 seconds when the temperature reaches 10 to 60 DEG C higher than the melting point of the brazing material, and taking the obtained product out of the furnace after the cooling. The polycrystal has high strength, can be independently used or added into a diamond tool to be used, and improve the performance and quality of the diamond tool.

Owner:WUHAN WAN BANG LASER DIAMOND TOOLS

Self-etching cementitious substrate coating composition

ActiveCN102186936BImprove adhesionHigh volume concentrationCoatingsThin material handlingSurface reactionSilanes

Coating compositions for cementitious substrates may be made from a multistage latex polymer; silane; and a water-soluble acid, acid anhydride or acid salt capable of etching or otherwise reacting with the surface of the substrate to provide improved coating adhesion. The silane my may be present as a silane coupling agent distinct from the multistage latex polymer, or may be present as silane functionality on the multistage latex polymer. The coating compositions adhere well to cementitious substrates and have a self-etching capability which improves coating adhesion, especially near edges and corners.

Owner:SWIMC LLC

Staining reagents and other liquids and related technologies for biological specimen tissue processing

Owner:VENTANA MEDICAL SYST INC

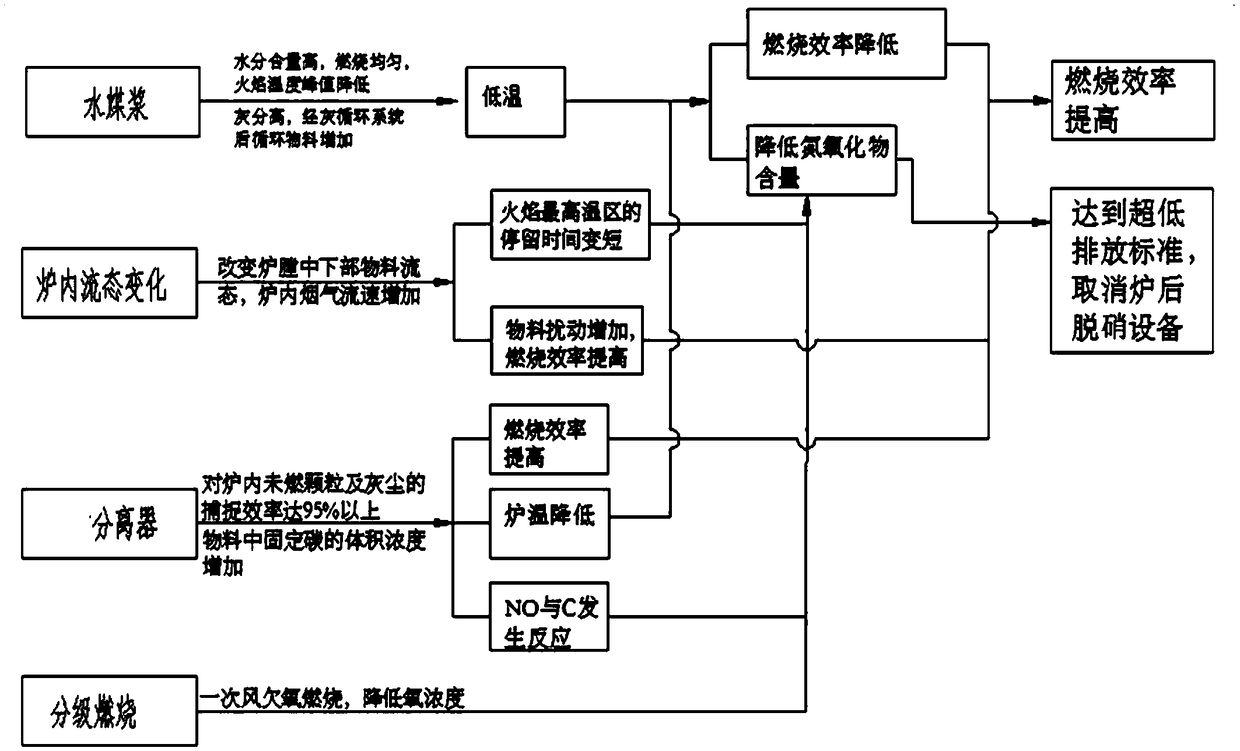

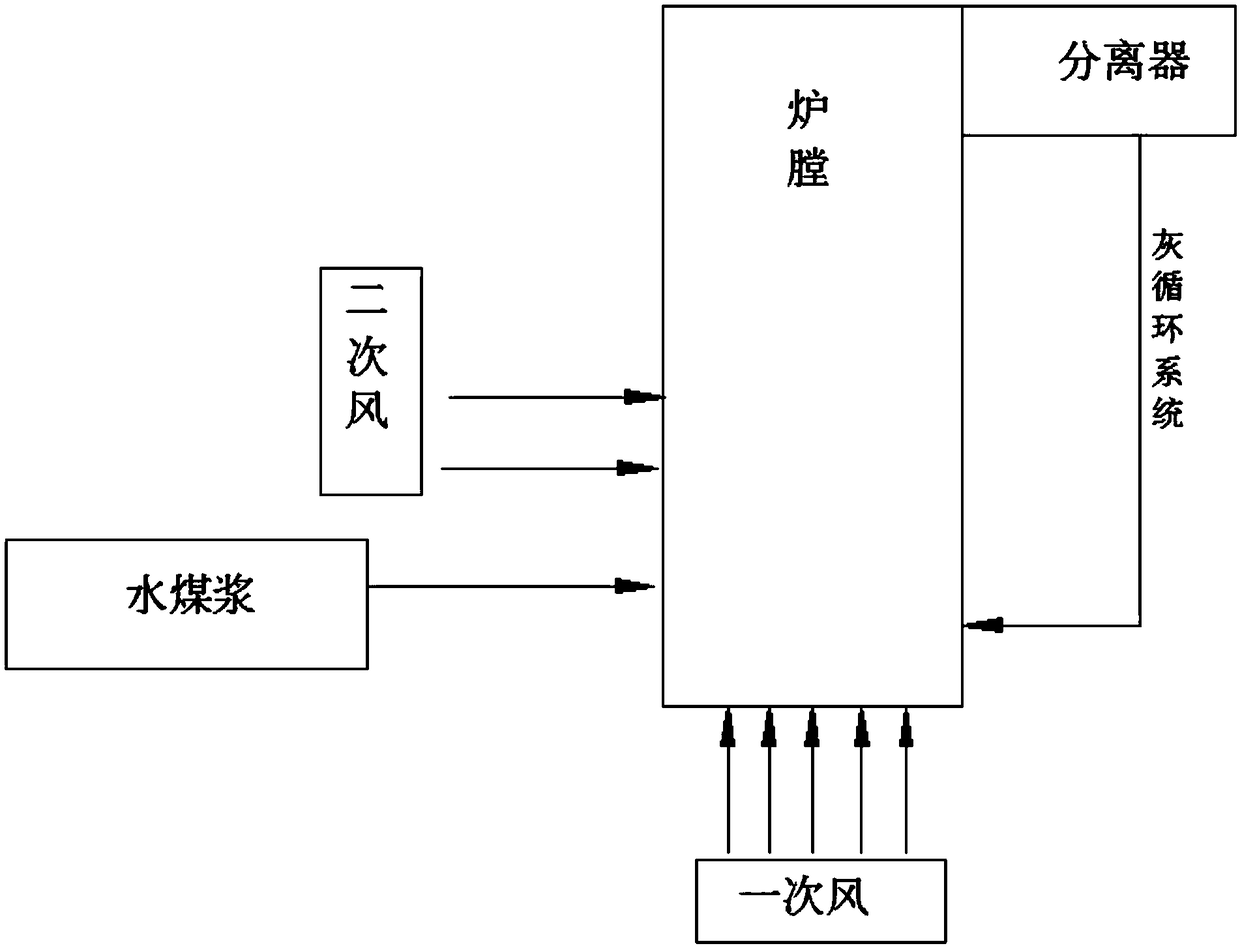

Low-nitrogen combustion process of circulating fluidized combustion boiler

InactiveCN108916867AReduce the temperatureReduce generationFluidized bed combustionApparatus for fluidised bed combustionCoal waterBoiler furnace

The invention relates to a low-nitrogen combustion process of a circulating fluidized combustion boiler. Coal water slurry is fed into a boiler furnace of the circulating fluidized combustion boiler to be used as fuel, staged combustion of the fuel is conducted, primary air is fed from the bottom of the boiler furnace, secondary air is fed from the side wall of the boiler furnace, high-temperatureflue gas in the furnace is subjected to solid-gas separation before entering a flue, and solid particles obtained through separation are returned into the boiler furnace for circulation combustion. The modes of coal water slurry combustion, staged combustion and solid particle circulation combustion are comprehensively adopted, the combustion efficiency of the boiler can be improved, and nitrogenoxides generated by the combustion process can be reduced.

Owner:QINGDAO CLEAR ENVIRONMENT PROTECTION BOILER ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com