Heat-insulation cooling type water-based mixed paint and preparation method thereof

A thermal insulation and cooling, water-based technology, applied in coatings, reflective/signal coatings, etc., can solve problems such as increasing power consumption, affecting the normal use of workshops, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

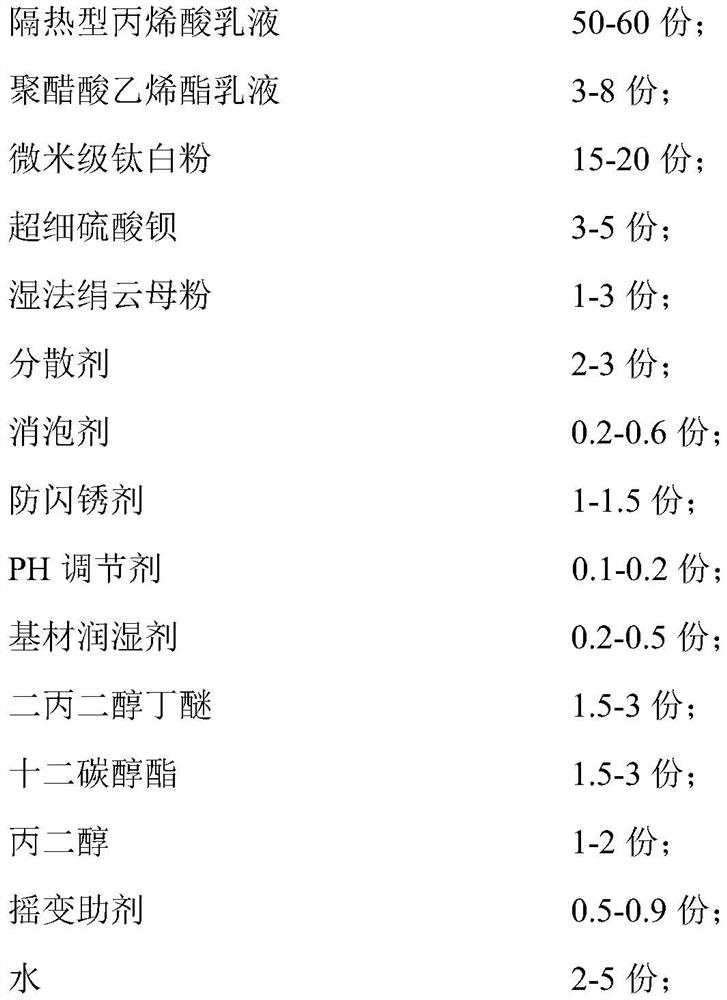

[0034] A heat-insulating and cooling-type water-based blending paint of the present embodiment is composed of the following raw materials in parts by weight:

[0035]

[0036] Among them, the crystal form of the micron-sized titanium dioxide is anatase; the particle size of the micron-sized titanium dioxide is 6 μm. Heat-insulating acrylic emulsion is Dow SR-01 heat-insulating acrylic emulsion. The mesh number of ultrafine barium sulfate is 3000 mesh. Wet-process sericite powder is Haiyang HY-TM3 wet-process sericite powder. The dispersant is a polycarboxylate ammonium dispersant. The defoamer is Puwei DF-226 defoamer. The anti-flash rust agent is Puwei FR-355 anti-flash rust agent. The pH regulator is Dow AMP-95PH regulator. The substrate wetting agent is Clariant Genapol x080 substrate wetting agent. The thixotropic additive is a mixture of Dow RM-3030, Dow RM-8W and Dow RM-12W in a mass ratio of 1:2:1.

[0037] The preparation method of the heat insulation and coo...

Embodiment 2

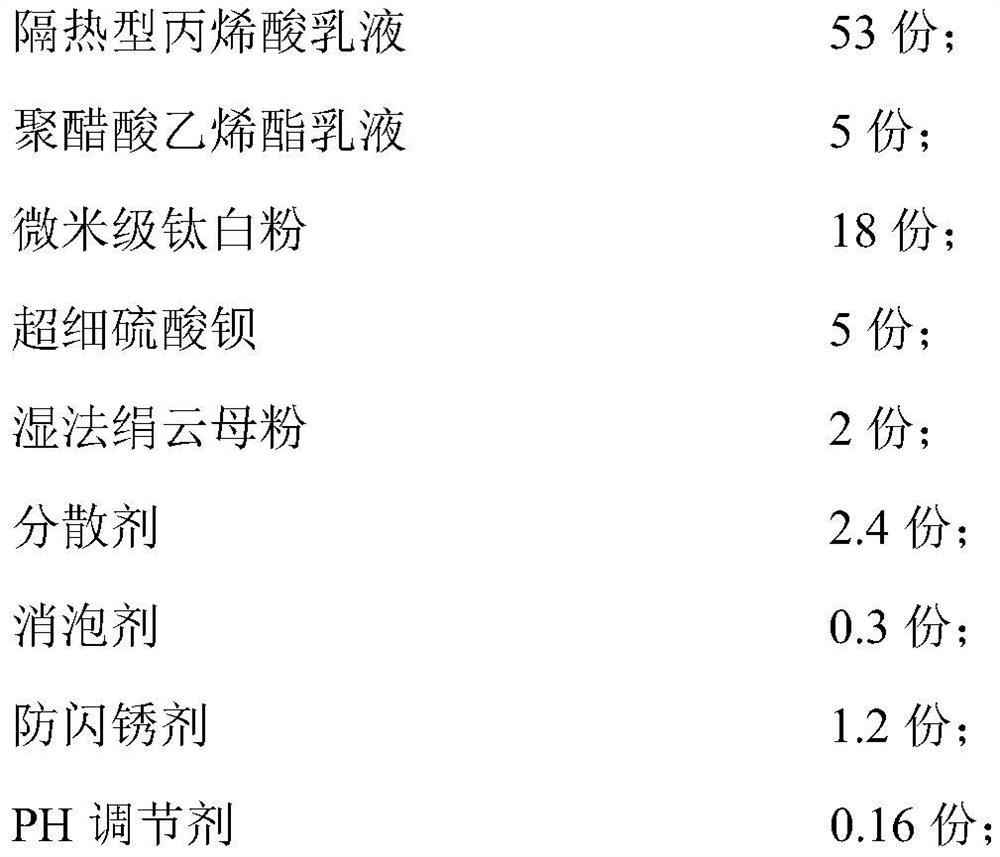

[0043] A kind of heat insulation cooling type water-based blending paint of the present embodiment is basically the same as embodiment 1, and its difference is as follows:

[0044] A heat-insulating and cooling-type water-based blending paint of the present embodiment is composed of the following raw materials in parts by weight:

[0045]

[0046] Wherein, the particle size of the micron-sized titanium dioxide is 8 μm.

[0047] Among them, the thixotropic additive is a mixture of Dow RM-3030, Dow RM-8W and Dow RM-12W in a mass ratio of 1:2.5:1.

[0048]The preparation method of the heat insulation and cooling type water-based blending paint of the present embodiment may further comprise the steps:

[0049] Step 1, adding the micron-sized titanium dioxide, ultrafine barium sulfate, wet-process sericite powder, dispersant, defoamer and water into a container, mixing and dispersing at 1000 rpm for 25 minutes to obtain a color paste;

[0050] Step 2, adding the heat-insulatin...

Embodiment 3

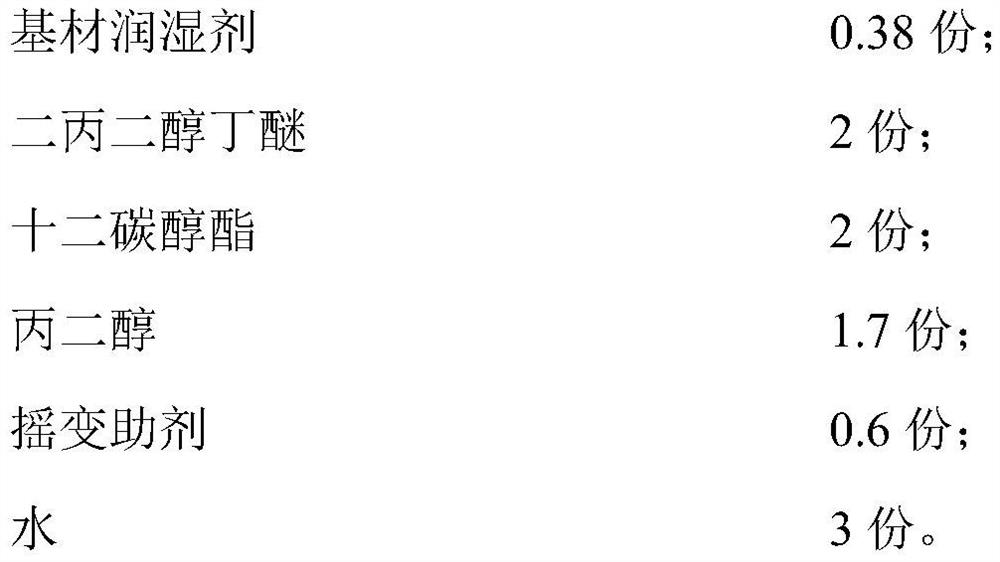

[0054] A kind of heat insulation cooling type water-based blending paint of the present embodiment is basically the same as embodiment 1, and its difference is as follows:

[0055] A heat-insulating and cooling-type water-based blending paint of the present embodiment is composed of the following raw materials in parts by weight:

[0056]

[0057] Wherein, the particle size of the micron-sized titanium dioxide is 5 μm.

[0058] Among them, the thixotropic additive is a mixture of Dow RM-3030, Dow RM-8W and Dow RM-12W in a mass ratio of 1:2.2:1.

[0059] The preparation method of the heat insulation and cooling type water-based blending paint of the present embodiment may further comprise the steps:

[0060] Step 1, adding the micron-sized titanium dioxide, ultrafine barium sulfate, wet-process sericite powder, dispersant, defoamer and water into a container, mixing and dispersing at 1000 rpm for 30 minutes to obtain a color paste;

[0061] Step 2, adding the heat-insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com