Octafluoropropane purifying method

An octafluoropropane and purification method technology, applied in the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of low production efficiency, insufficient removal depth, and high equipment requirements, reducing the number of regenerations and avoiding energy consumption Large, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

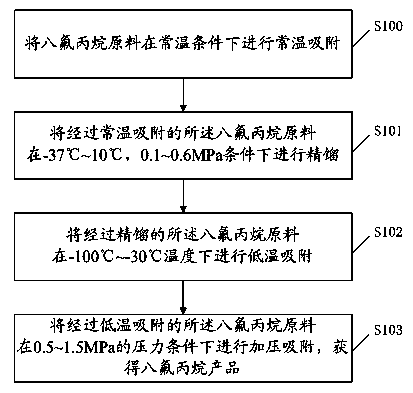

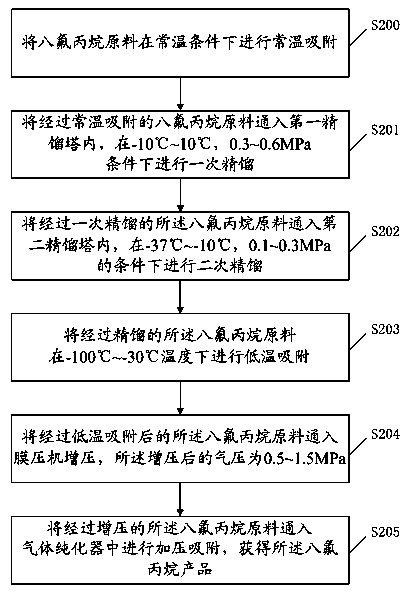

Method used

Image

Examples

Embodiment 1

[0093] Pass the octafluoropropane raw material into the normal temperature adsorber equipped with a molecular sieve mixed with 5A and 13X molecular sieve at 1:1.2 as the first adsorbent for normal temperature adsorption; pass the octafluoropropane raw material adsorbed at normal temperature into the first In the rectification tower, at 0°C, 0.4MPa, the vent flow is 2Nm 3 Carry out a rectification under the condition of one rectification; pass the octafluoropropane raw material through the first rectification into the second rectification tower, at -10°C, 0.3MPa, and the vent flow rate is 0.5Nm 3 Secondary rectification is carried out under the condition of / h; the rectified octafluoropropane raw material is placed at a temperature of -75°C, and the second adsorbent used includes CO 2 The special adsorbent is the second adsorbent a and 3A molecular sieve is used as the second adsorbent b for low-temperature adsorption; the octafluoropropane raw material that has been adsorbed a...

Embodiment 2

[0095] Pass the octafluoropropane raw material into the normal temperature adsorber equipped with a molecular sieve mixed with 5A and 13X molecular sieve at 1:1.5 as the first adsorbent for normal temperature adsorption; pass the octafluoropropane raw material adsorbed at normal temperature into the first In the rectification tower, at 10°C, 0.6MPa, the vent flow rate is 0.2Nm 3 Carry out a rectification under the condition of one rectification; pass the octafluoropropane raw material through the first rectification into the second rectification tower, at -5°C, 0.1MPa, and the vent flow is 0.7Nm 3 Secondary rectification is carried out under the condition of / h; the rectified octafluoropropane raw material is placed at a temperature of -55°C, and the second adsorbent used includes CO 2 The special adsorbent is the second adsorbent a and the molecular sieve mixed with 4A and 13X molecular sieve at 1:1.2 is the second adsorbent b for low-temperature adsorption; Under pressure c...

Embodiment 3

[0097] Pass the octafluoropropane raw material into the normal temperature adsorber equipped with a molecular sieve mixed with 5A and 13X molecular sieve at 1:1 as the first adsorbent for normal temperature adsorption; pass the octafluoropropane raw material adsorbed at normal temperature into the first In the rectification tower, at -10°C, 0.5MPa, the vent flow is 1.8Nm 3 Carry out a rectification under the condition of one rectification; pass the octafluoropropane raw material through the first rectification into the second rectification tower, at -20°C, 0.2MPa, and the vent flow rate is 1.0Nm 3 Secondary rectification is carried out under the condition of / h; the second adsorbent used includes CO 2 The special adsorbent is the second adsorbent a and 5A molecular sieve is used as the second adsorbent b for low-temperature adsorption; the octafluoropropane raw material that has undergone low-temperature adsorption is under the pressure condition of 1.2MPa, and is made of 5A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com