Production method of nano calcium carbonate

A technology of nano-calcium carbonate and production methods, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, carbon compounds, etc., can solve the problems of wide product particle size distribution, long production cycle, etc., achieve shortened production cycle, production The effect of short cycle and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

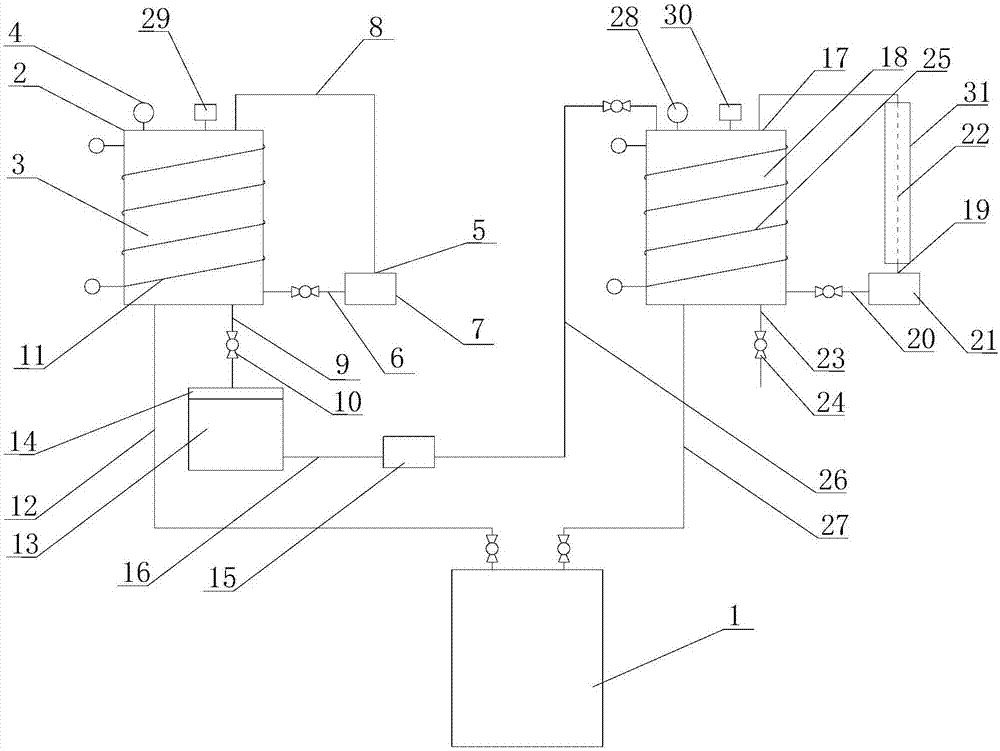

[0033] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

[0034] A kind of production method of nanometer calcium carbonate, comprises the following steps:

[0035] (1) calcining: get natural limestone, and carry out high-temperature calcining in calcining kiln, obtain CaO and kiln gas; CO in the kiln gas 2 The gas is separated and liquefied into tanks to obtain C0 2 Output tank 1.

[0036] (2) Digestion: remove impurities from CaO in step (1) and then add water for digestion, the water temperature is 80-100° C. to obtain Ca(OH)2 suspension. In this embodiment, the water temperature is 90°C.

[0037] (3) Sizing: the temperature of the Ca(OH)2 suspension obtained in step (2) is controlled at 18-22° C., the solid content is controlled at 9-13%, and a crystal form control agent is added to obtain a fine slurry. The crystal form control agent is one or more of triethanolamine, tartaric acid, citric acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com