Device and method for collecting nitrogen gas from cyclohexane oxidized tail gas

A technology for oxidizing tail gas and cyclohexane, applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds, etc., can solve the problems of waste of resources, waste of resources, environment, pollution, etc., achieve significant social and economic benefits, reduce emissions, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

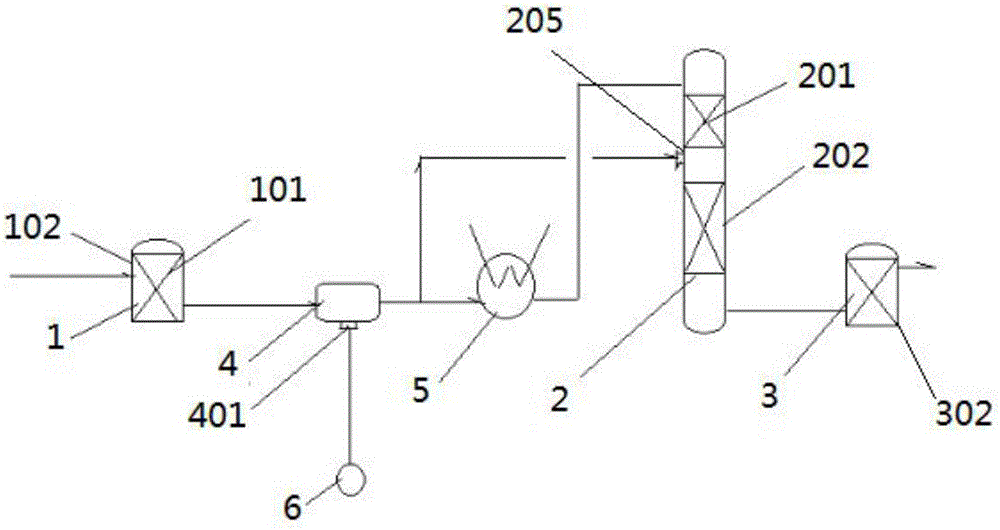

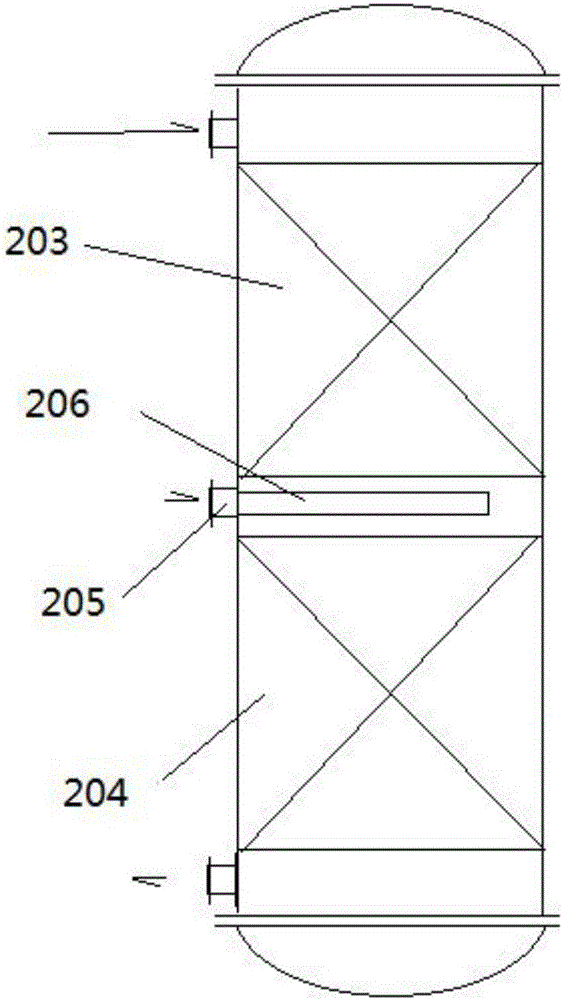

[0061] use figure 1 process and figure 2 of the reactor.

[0062] Basic parameters:

[0063] In the oxidation tail gas of the cyclohexane air oxidation device, the volume concentration of nitrogen is 96.4%;

[0064] The temperature-swinging adsorbent is activated carbon;

[0065] The catalyst is dehydrogenation catalyst, there are low-temperature type and high-temperature type, and it is mixed packing;

[0066] The pressure swing adsorbent is activated carbon.

[0067] (1) Temperature swing adsorption, the operating conditions are as follows:

[0068] The temperature is 25°C, the residence time of the oxidation tail gas in the temperature swing adsorption device 1 is 14 hours, and the pressure is 0.9MPa;

[0069] (2) The weight ratio of temperature swing adsorption gas to compressed air is: temperature swing adsorption gas:compressed air=8:1;

[0070] (3) The mixed gas of the intermediate mixer 4 partially enters the heating device 5, is heated to a temperature of 230°...

Embodiment 2

[0081] use figure 1 process and figure 2 the reactor

[0082] Basic parameters:

[0083] In the oxidation tail gas of the cyclohexane air oxidation device, the volume concentration of nitrogen is 96.4%;

[0084] The temperature-swinging adsorbent is activated carbon;

[0085] The catalyst is dehydrogenation catalyst, there are low-temperature type and high-temperature type, and it is mixed packing;

[0086] The pressure swing adsorbent is a molecular sieve.

[0087] (1) Temperature swing adsorption, the operating conditions are as follows:

[0088] The temperature is 30°C, the residence time of the oxidation tail gas in the temperature swing adsorption device 1 is 16 hours, and the pressure is 1MPa;

[0089] (2) The weight ratio of temperature swing adsorption gas to compressed air is: temperature swing adsorption gas:compressed air=10:1;

[0090] (3) The mixed gas of the intermediate mixer 4 partially enters the heating device 5, is heated to a temperature of 210° C.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com