Method and device for producing black copper by sludge containing copper

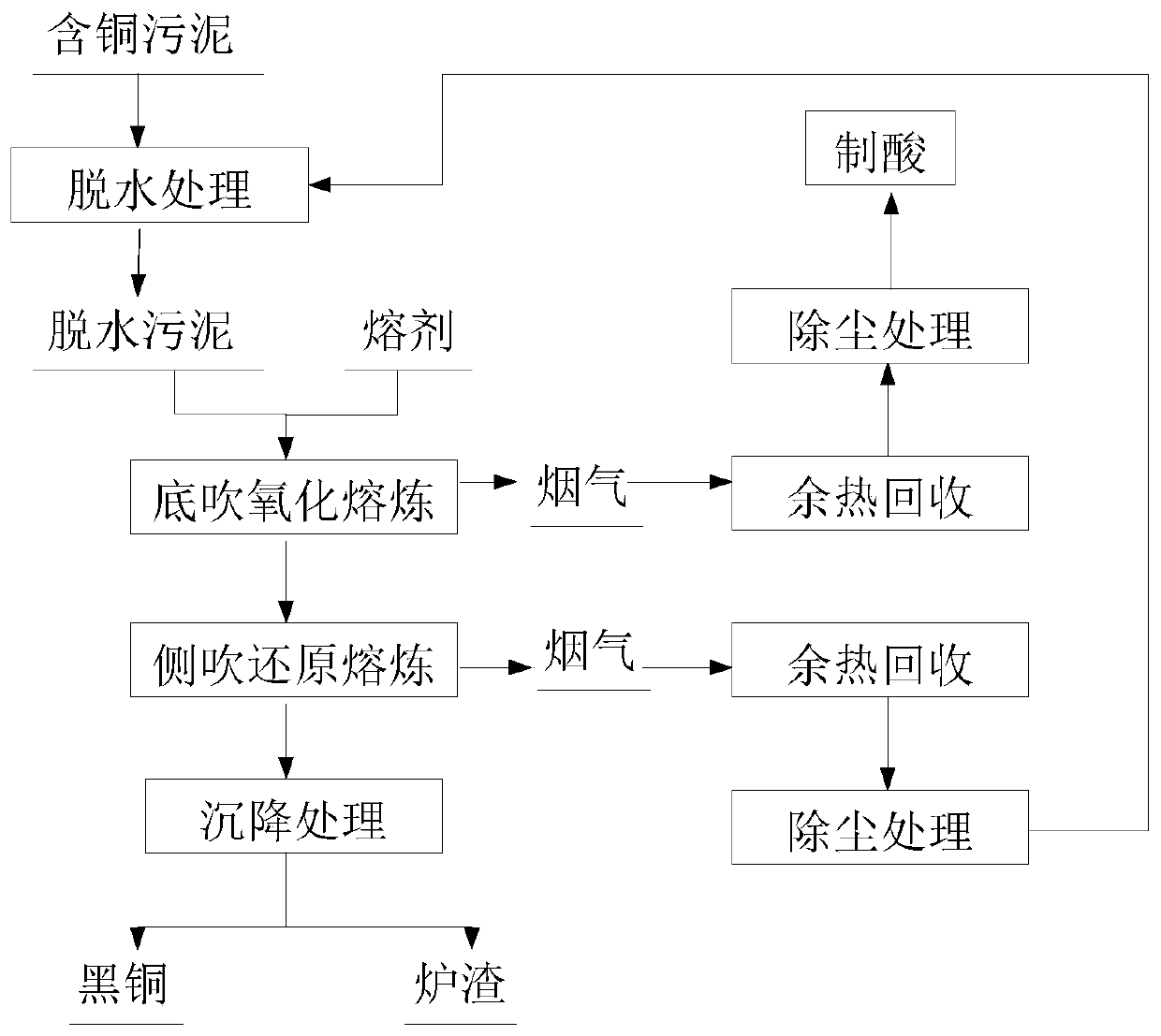

A technology of copper sludge and black copper, applied in the metallurgical field, can solve the problems of high sulfur content and long process, achieve the effect of low content of harmful substances, improve recovery rate, and solve long process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The copper-containing sludge with a water content of 75% is put into a rotary kiln for drying. The inlet temperature of the flue gas at the tail of the drying kiln is about 150°C, and it is dried under the flue gas at 150°C until the water content is about 20% and it is granular.

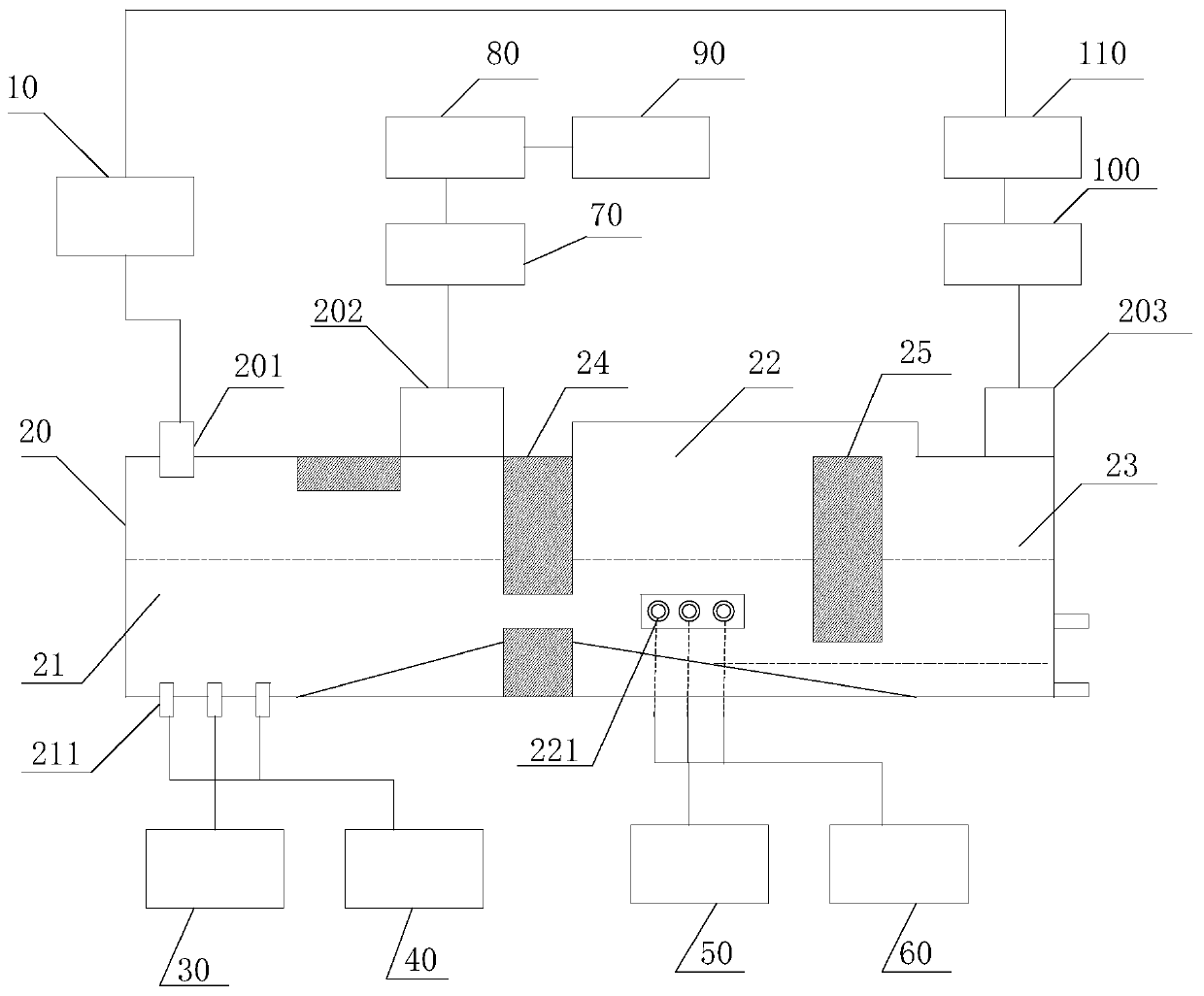

[0074] Every ton of copper-containing sludge (water content 20%) needs to be added with 57kg of silica, and the sludge and silica are mixed and put into figure 2 The melt pool in the bottom-blown oxidation zone shown is protected by water-cooled furnace walls, water-cooled lance refractories and lance hanging slag. Bottom-blown pure oxygen and coal powder are used to process 100kg of coal powder and 12Nm of air per ton of sludge (water content 20%) 3 (Powder spraying carrier gas), oxygen 294Nm 3 . The molten pool is all slag, the temperature of the molten pool is 1250-1350°C, and the SO in the flue gas 2 , O 2 The volume contents are 5.05% and 4.65% respectively. The flue gas is passed t...

Embodiment 2

[0078] The treatment method is the same as that of Example 1, but the sludge drying degree is higher, and the water content is about 10%. Oxygen-enriched air with an oxygen concentration of 90% is used for bottom blowing and side blowing combustion for heat supply, and the temperature of the melt pool in the furnace is controlled to be higher.

[0079] The copper-containing sludge with a water content of 75% is put into a rotary kiln for drying. The inlet temperature of the flue gas at the tail of the drying kiln is about 150°C, and it is dried under the flue gas at 150°C until the water content is about 10%, and it is granular.

[0080] Every ton of copper-containing sludge (water content 10%) needs to be added with 64kg of silica, and the sludge and silica are mixed and put into figure 2 The melt pool in the bottom-blown oxidation zone shown is protected by water-cooled furnace walls, water-cooled lance refractories and lance hanging slag. Bottom-blown pulverized coal and o...

Embodiment 3

[0084] The treatment method is the same as that of Example 1, but the drying degree of the sludge is low, and the water content is about 40%. Oxygen-enriched air with an oxygen concentration of 95% is used for bottom blowing and side blowing combustion for heat supply, and the temperature of the melting pool in the furnace is controlled to be low.

[0085] The copper-containing sludge with a water content of 75% is put into a rotary kiln for drying. The inlet temperature of the flue gas at the drying kiln tail is about 150°C, and it is dried under the flue gas at 150°C to a water content of about 40%.

[0086] Every ton of copper-containing sludge (water content 40%) needs to be added with 42.5kg of silica, and the sludge and silica are mixed and put into figure 2The melt pool in the bottom-blown oxidation zone shown is protected by water-cooled furnace walls, water-cooled lance refractories and lance hanging slag. Bottom-blown pulverized coal and oxygen-enriched (95% oxygen-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com