Color masterbatch plastic grade titanium dioxide and preparation method thereof

A technology of titanium dioxide and color masterbatch, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problem of poor photocatalytic performance of single aluminum coating, poor compatibility and dispersion performance of titanium dioxide, Problems such as inconvenience in downstream terminal applications, to achieve the effect of improving compatibility and machinability, excellent compatibility, and strengthening compatibility and machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

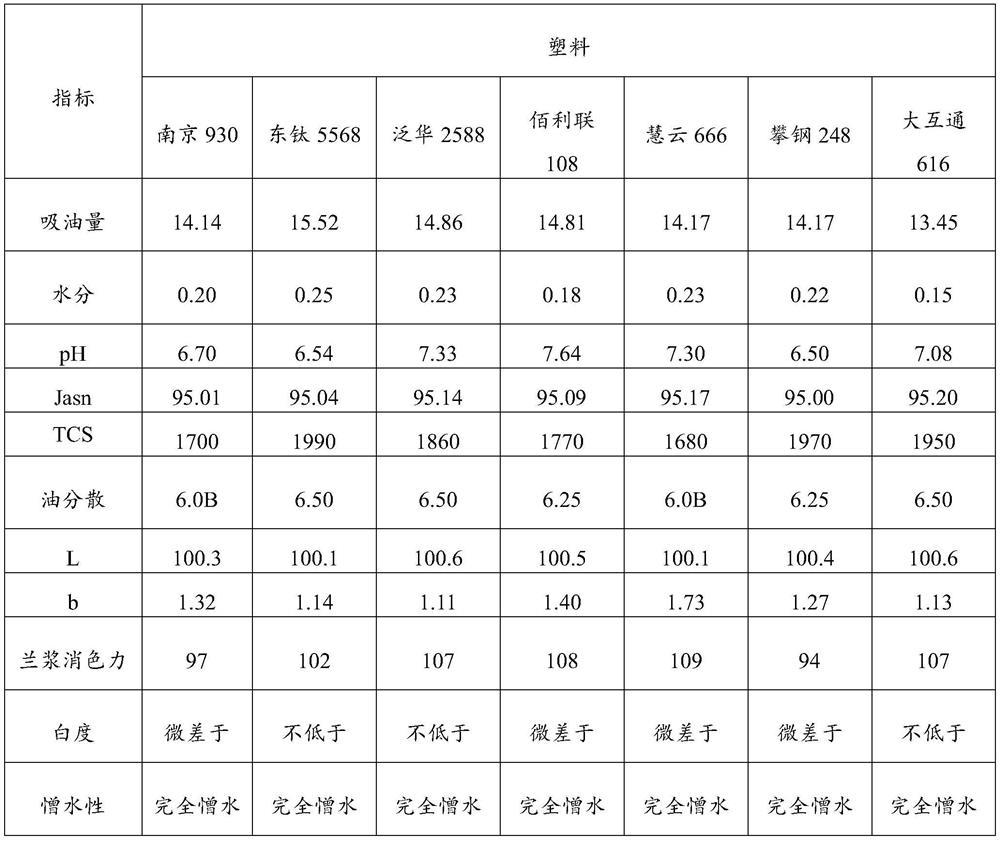

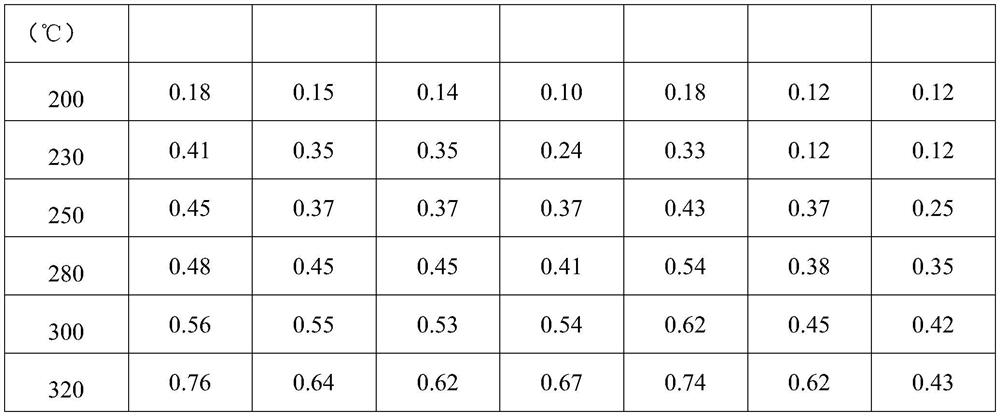

Examples

Embodiment 1

[0031] A plastic master grade titanium dioxide, the titanium dioxide includes an inner core and a coating layer coated on the inner core, the inner core is rutile titanium dioxide, the coating layer includes a first organic film layer coated on the inner core, and a coating layer coated on the second An inorganic film layer on an organic film layer and a second organic film layer coated on the inorganic film layer;

[0032] The first organic film layer is obtained by the reaction of titanium dioxide and the first organic coating agent, the first organic coating agent comprises polyacrylic acid emulsion and phosphate, the polyacrylic acid emulsion accounts for 0.1% of the total weight of titanium dioxide, and the phosphate accounts for the total weight of titanium dioxide 0.15% of;

[0033] The inorganic film layer has two layers, the layer close to the first organic coating layer contains zirconia, which accounts for 0.6% of the total weight of titanium dioxide, and the layer ...

Embodiment 2

[0050] A plastic master grade titanium dioxide, the titanium dioxide includes an inner core and a coating layer coated on the inner core, the inner core is rutile titanium dioxide, the coating layer includes a first organic film layer coated on the inner core, and a coating layer coated on the second An inorganic film layer on an organic film layer and a second organic film layer coated on the inorganic film layer;

[0051] The first organic film layer is obtained by the reaction of titanium dioxide and the first organic coating agent. The first organic coating agent includes polyacrylic acid emulsion and phosphate. The polyacrylic acid emulsion accounts for 0.3% of the total weight of titanium dioxide, and the phosphate accounts for the total weight of titanium dioxide. 0.08% of;

[0052] The inorganic film layer has two layers, the layer close to the first organic coating layer contains zirconia, which accounts for 0.3% of the total weight of titanium dioxide, and the layer ...

Embodiment 3

[0069] A plastic master grade titanium dioxide, the titanium dioxide includes an inner core and a coating layer coated on the inner core, the inner core is rutile titanium dioxide, the coating layer includes a first organic film layer coated on the inner core, and a coating layer coated on the second An inorganic film layer on an organic film layer and a second organic film layer coated on the inorganic film layer;

[0070] The first organic film layer is obtained by the reaction of titanium dioxide and the first organic coating agent, the first organic coating agent comprises polyacrylic acid emulsion and phosphate, the polyacrylic acid emulsion accounts for 0.2% of the total weight of titanium dioxide, and the phosphate accounts for the total weight of titanium dioxide 0.1% of;

[0071] The inorganic film layer has two layers, the layer close to the first organic coating layer contains zirconia, which accounts for 0.4% of the total weight of titanium dioxide, and the layer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com