Multi-stage capillary pump

A capillary pump and capillary technology, which is applied in the field of alkali metal thermoelectric direct conversion devices, can solve problems such as affecting the efficiency of thermoelectric converters, and achieve the effects of avoiding interruption of alkali metal working medium, full circulation, and avoiding dry burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

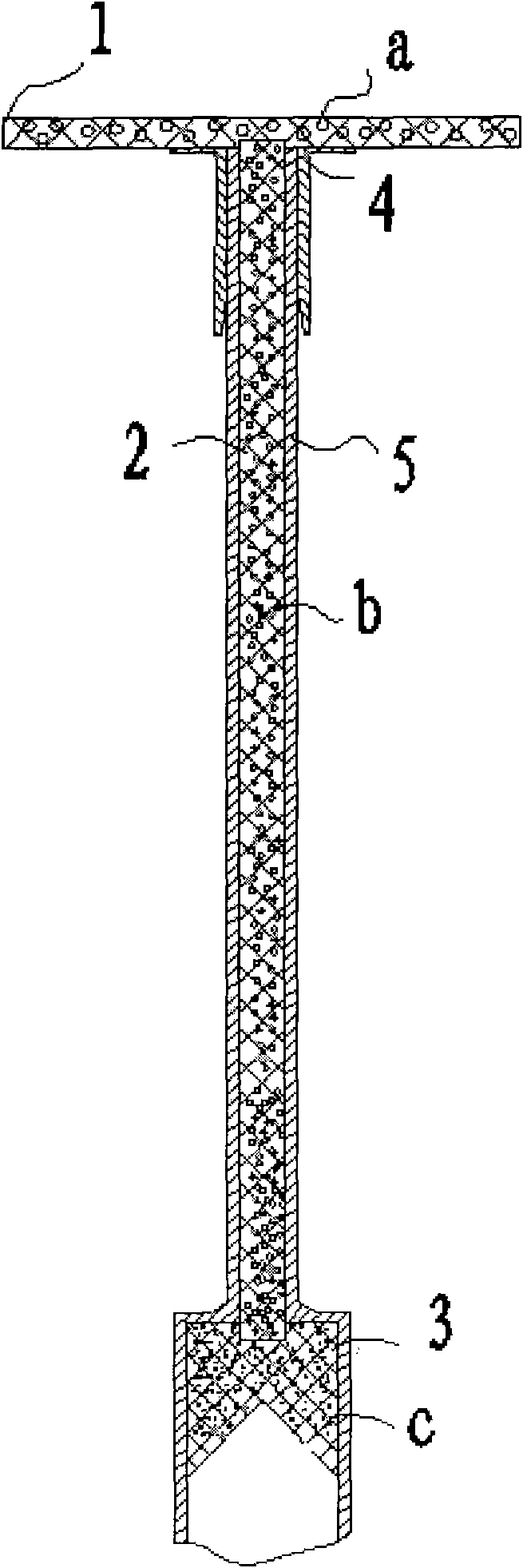

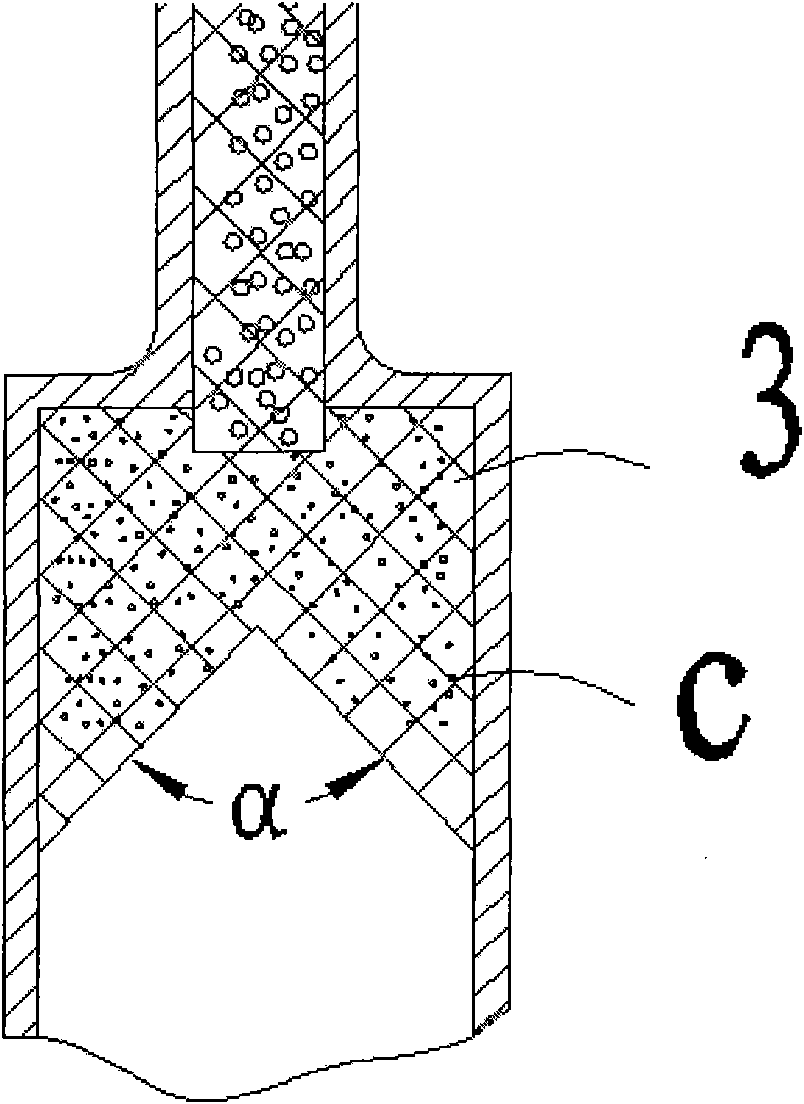

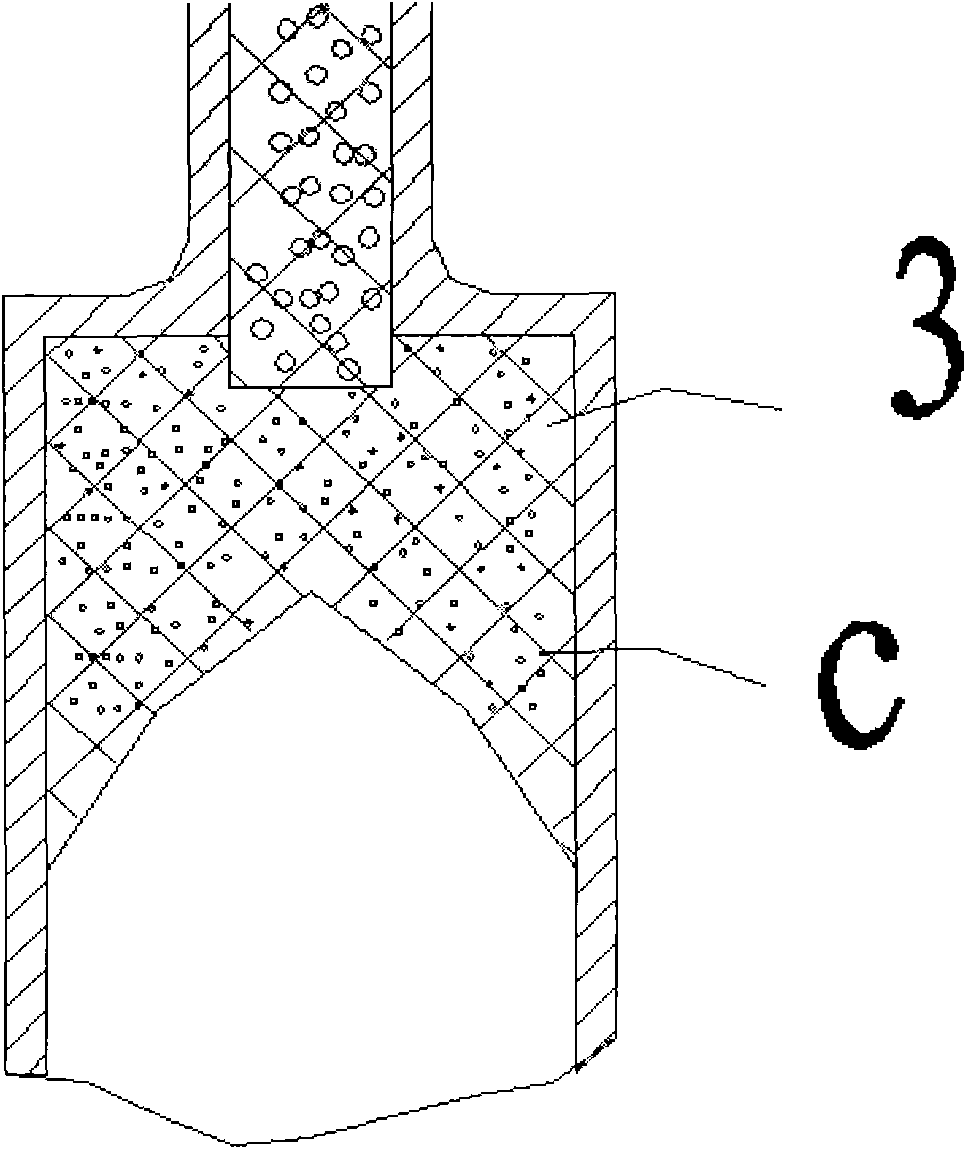

[0023] combine figure 1 , the main components of the first embodiment of the present invention are all porous structures. Therefore, according to the aperture size, the device of the present invention can be divided into three stages. The first stage porous structure is the condenser 1 . The second level of porous structure is the capillary channel 2 . The third level porous structure is the evaporator 3 . The condenser is directly connected to the capillary passage. In order to ensure the stability of the condenser, a supporting frame can be used to support it. The capillary passage is connected with the evaporator by a refractory metal sleeve 4 . There are stainless steel sleeves 5 in the capillary passage and the outer jacket of the evaporator, and vacuum welding is used between the evaporator and the stainless steel sleeve to ensure the sealing performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertex angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com