Technology and equipment for electric heating regeneration of activated carbon

A technology of activated carbon and electric heating, applied in filter regeneration, petroleum industry, filtration and separation, etc., can solve the problems of high loss of activated carbon, long regeneration time, and high energy consumption, to avoid energy consumption, avoid direct contact, and reduce loss rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

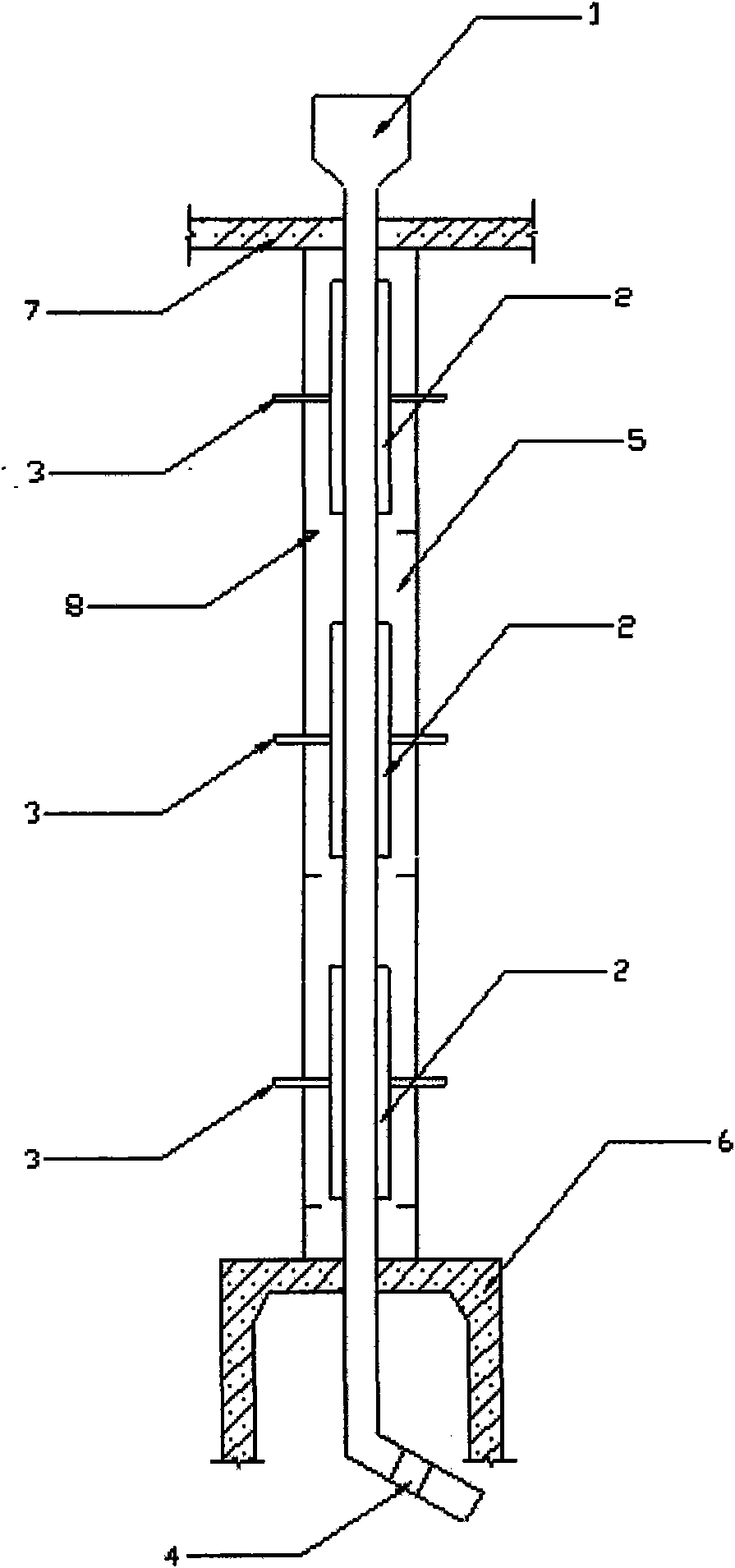

[0026] A kind of specific embodiment of the present invention is described below in conjunction with accompanying drawing:

[0027] In this embodiment, the production capacity of the activated carbon electrothermal regeneration process is 75Kg / h.

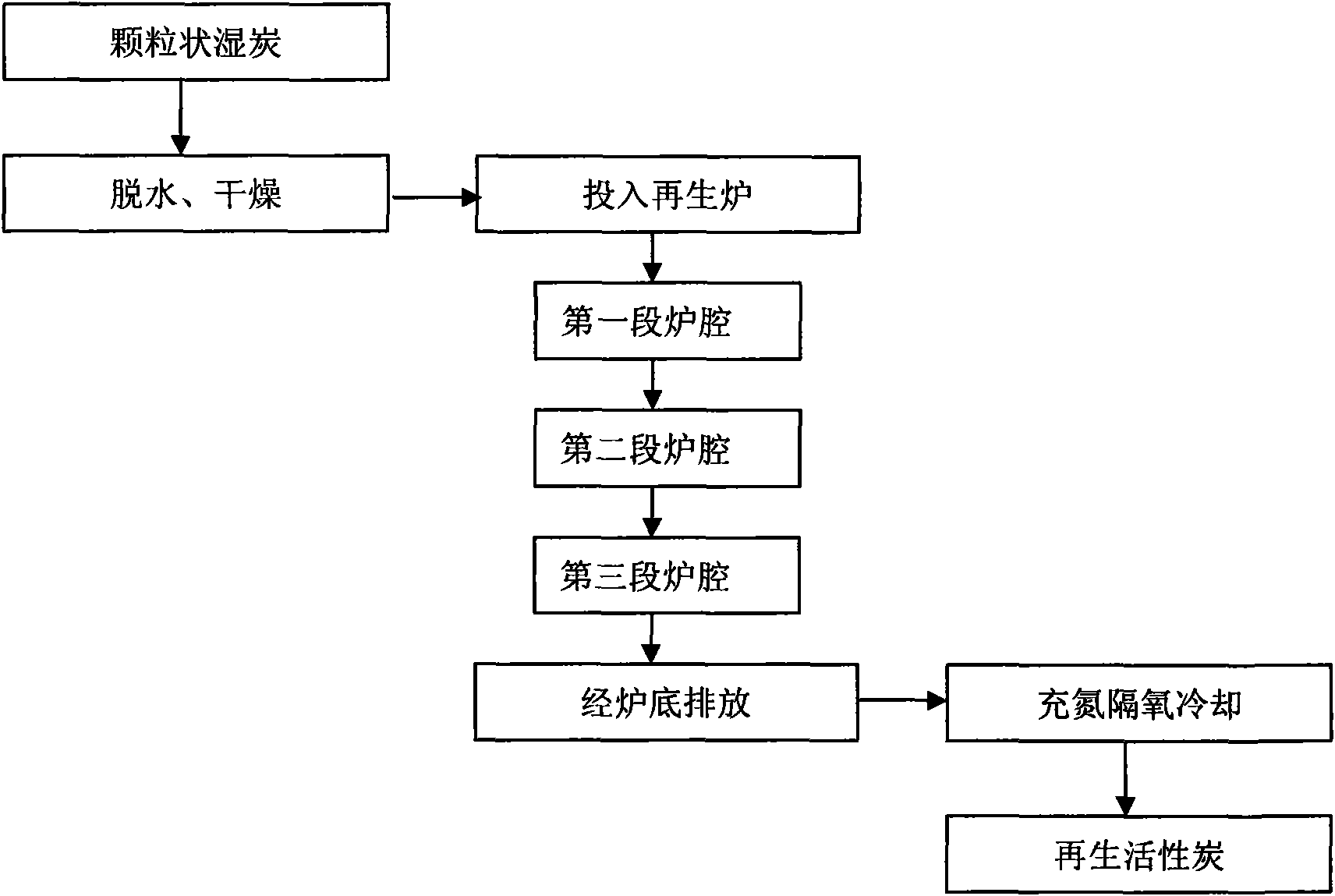

[0028] The granular wet carbon produced in the water treatment process is dehydrated by the dehydration tank, sucked into the fluidized bed by negative pressure, and dried in the hot air at 200-250°C to reduce the moisture content to 6%.

[0029] The dehydrated and dried carbon particles are put into the electric heating regeneration furnace through the feed port, and the carbon particles pass through the furnace cavity between the graphite electrodes in turn, and the arc is excited to make the carbon particles conductively heated, and the temperature of the carbon particles in the furnace cavity increases gradually from top to bottom, and the carbon particles The linear velocity of particles moving in the furnace cavity is 5.83m / s....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com