Processing method of mother liquor of ainothiazoly loximate

A treatment method of aminothiaxamic acid, applied in organic chemistry, ultrafiltration, etc., can solve the problems of high energy consumption, high COD and BOD, and increased sewage treatment costs for concentrated recovery of aminothiaxamic acid, and achieve the reduction of COD and BOD and other indicators , Guaranteed quality, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

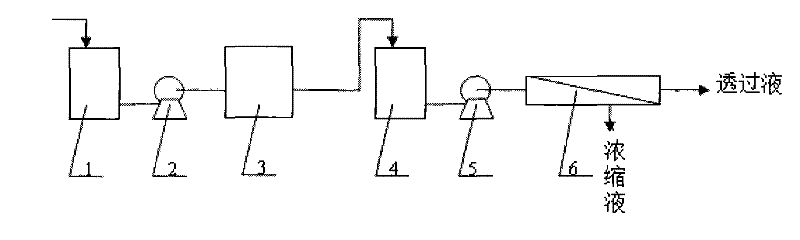

Method used

Image

Examples

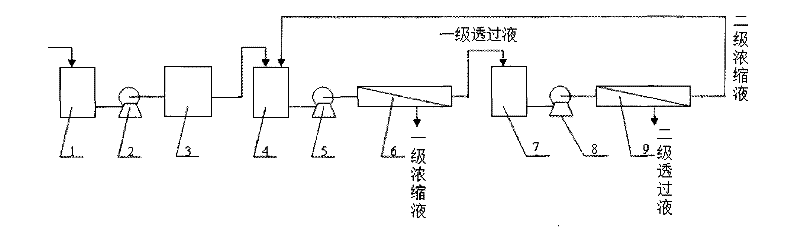

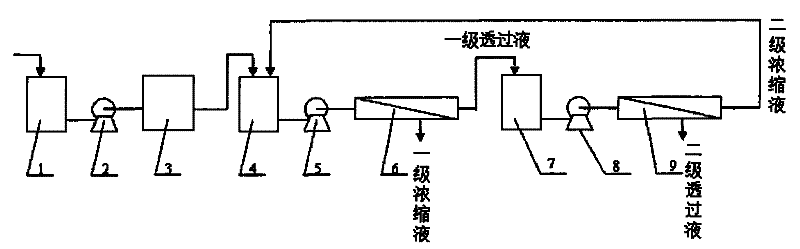

Embodiment 1

[0019] Put the aminothiaxamic acid mother liquor with a content of 1%, pH=6, and a temperature of 25°C in the raw water tank, and pump the aminothiaxamic acid mother liquor into a precision filter with a filtration accuracy of 4.5 μm by a booster pump under the operating condition of a pressure of 0.2 MPa Pretreatment is carried out, and the pretreated mother liquor enters the first-stage circulating water tank, and then is pumped into the first-stage nanofiltration component by the high-pressure pump under the operating pressure of 1.8MPa. The concentration of aminothioxamic acid in the first-stage nanofiltration concentrate can reach about 10%. After being discharged from the system, the crystallization process continues. The first-stage nanofiltration permeate enters the second-stage circulating water tank, and then is pressurized to 1.5MPa by the second-stage high-pressure pump, and enters the second-stage nanofiltration component for treatment. The concentrated liquid of th...

Embodiment 2

[0021] The aminothiaxamic acid mother liquor with a content of 1%, pH=7, and a temperature of 20°C is placed in the raw water tank, and the aminothiaxamic acid mother liquor is pumped into a cloth bag filter with a filtration accuracy of 5 μm by a booster pump under the operating condition of a pressure of 0.3 MPa. Pretreatment, the pretreated mother liquor enters the first-level circulating water tank, and then is pumped into the first-level nanofiltration component by the high-pressure pump under the operating pressure of 2.0MPa. The concentration of aminothioxamic acid in the first-level nanofiltration concentrate can reach about 10%, and is discharged After the system, the crystallization process continues. The first-stage nanofiltration permeate enters the second-stage circulating water tank, and then is pressurized to 1.6MPa by the second-stage high-pressure pump, and enters the second-stage nanofiltration component for treatment. The concentrated liquid of the second-stag...

Embodiment 3

[0023] Put the aminothiaxamic acid mother liquor with a content of 1%, pH=8, and a temperature of 20°C in the raw water tank, and pump the aminothiaxamic acid mother liquor into a ceramic membrane filter with a filtration accuracy of 0.5 μm by a booster pump under the operating condition of a pressure of 1.0 MPa The pretreated mother liquor enters the first-stage circulating water tank, and then is pumped into the first-stage nanofiltration component by the high-pressure pump under the operating pressure of 2.3MPa. The concentration of aminothioxamic acid in the first-stage nanofiltration concentrate can reach about 10%. , after being discharged from the system, the crystallization process continues. The first-stage nanofiltration permeate enters the second-stage circulating water tank, and then is pressurized to 1.8MPa by the second-stage high-pressure pump, and then enters the second-stage nanofiltration component for treatment, and the concentrated liquid of the second-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com